Method for controlling salt and alkali in basin tidal flat

A tidal flat and watershed technology, applied in construction, application, soil drainage, etc., can solve the problems of easy silting, collapse, salinity and alkali drainage, shallow depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

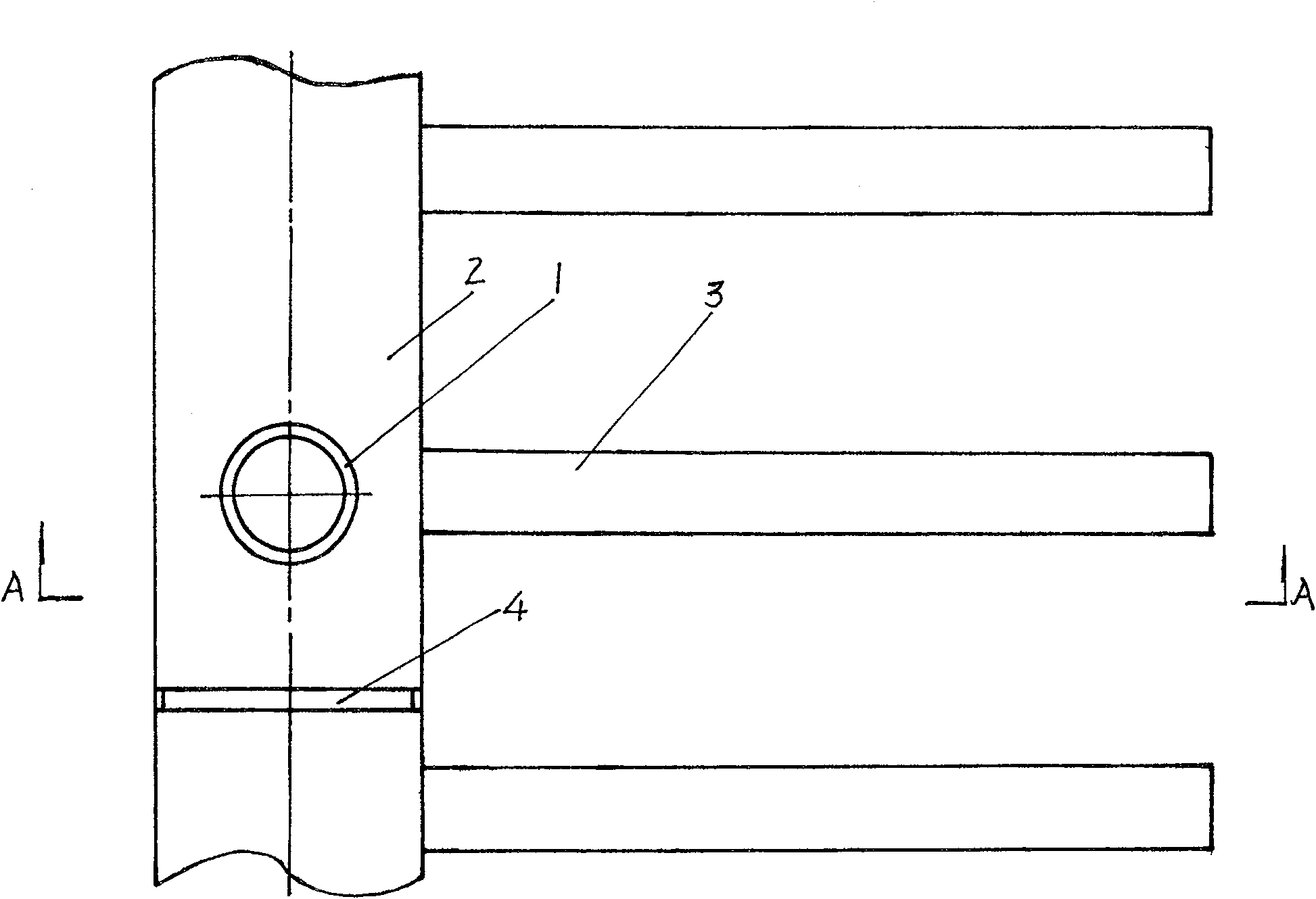

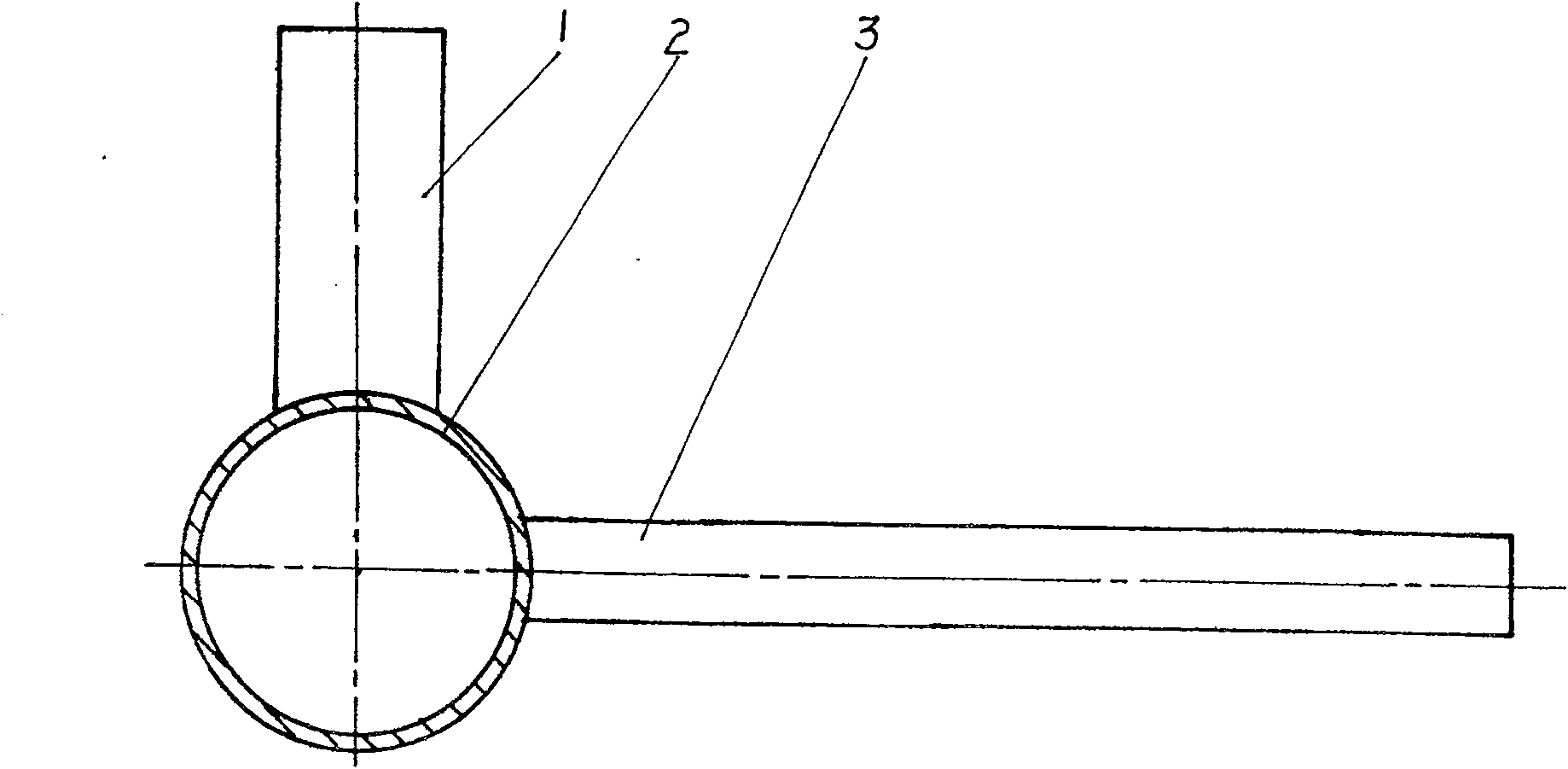

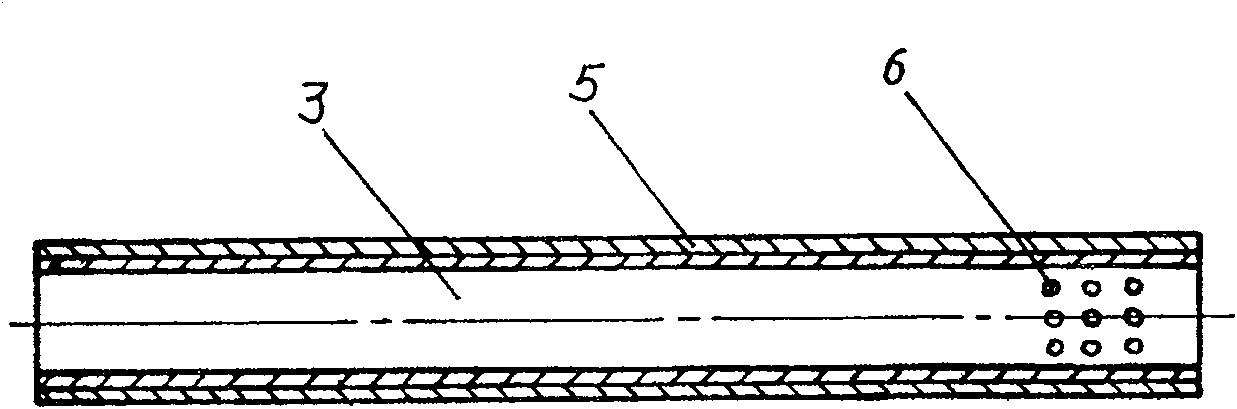

[0017] like figure 1 , figure 2 and image 3 Shown, the method for controlling river basin tidal flat saline-alkali in the present embodiment, it may further comprise the steps:

[0018] A, at first on the hollow branch pipe 3 that the diameter that PVC plastic is made is 2cm, process out some rows of sieve holes 6 that the diameter is 1mm, and the distance between every row of sieve holes 6 is 1cm;

[0019] B, wrapping 2 layers of mesh bags 5 on the outer surface of the hollow branch pipe 3 processed through the sieve holes;

[0020] c, burying a main pipeline 2 with a diameter of 1m in the tidal flats of the watershed, and its depth is 1.7m;

[0021] d. In the tidal flats of the watershed, dig a channel with a depth of 1.5m to bury the hollow branch pipe 3 every 5-10m, then put the hollow branch pipe 3 and lay 4mm thick fine sand around the hollow branch pipe 3 to wrap the hollow branch pipe 3 live, one end of each hollow branch pipe 3 is connected with the main pipe 2,...

Embodiment 2

[0024] like figure 1 , figure 2 and image 3 Shown, the method for controlling river basin tidal flat saline-alkali in the present embodiment, it may further comprise the steps:

[0025] A, at first on the hollow branch pipe 3 that the diameter that PVC plastic is made is 5cm, process out some row diameters and be the sieve holes 6 of 5mm, the distance between every row of sieve holes 6 is 2cm;

[0026] B, winding 3 layers of mesh bags 5 on the outer surface of the hollow branch pipe 3 with the sieve holes processed;

[0027] c. Embedding a main pipeline 2 with a diameter of 1.5m in the tidal flats of the river basin and a depth of 2.2m;

[0028] d. In the tidal flats of the river basin, dig a channel with a depth of 2.0m to bury the hollow branch pipe 3 every 5-10m, then put the hollow branch pipe 3 and lay 4mm thick fine sand around the hollow branch pipe 3 to wrap the hollow branch pipe 3 live, one end of each hollow branch pipe 3 is connected with the main pipe 2, and...

Embodiment 3

[0031] like figure 1 , figure 2 and image 3 Shown, the method for controlling river basin tidal flat saline-alkali in the present embodiment, it may further comprise the steps:

[0032] A, at first on the hollow branch pipe 3 that the diameter that PVC plastic is made is 4cm, process out some row diameters and be the sieve holes 6 of 3mm, the distance between every row of sieve holes 6 is 1.5cm;

[0033] B, winding 3 layers of mesh bags 5 on the outer surface of the hollow branch pipe 3 with the sieve holes processed;

[0034] c, bury the main pipeline 2 with a diameter of 1.3m in the tidal flats of the watershed, and its depth is 1.9m;

[0035] d. In the tidal flats of the watershed, dig a channel with a depth of 1.7m to bury the hollow branch pipe 3 every 5-10m, then put the hollow branch pipe 3 and lay 4mm thick fine sand around the hollow branch pipe 3 to wrap the hollow branch pipe 3 live, one end of each hollow branch pipe 3 is connected with the main pipe 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com