Device for placing an object

A technology of objects and actuators, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems of unstable movement of objects, aggravation, and affecting the positioning accuracy of objects, so as to achieve simple alternate contact and solve placement problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

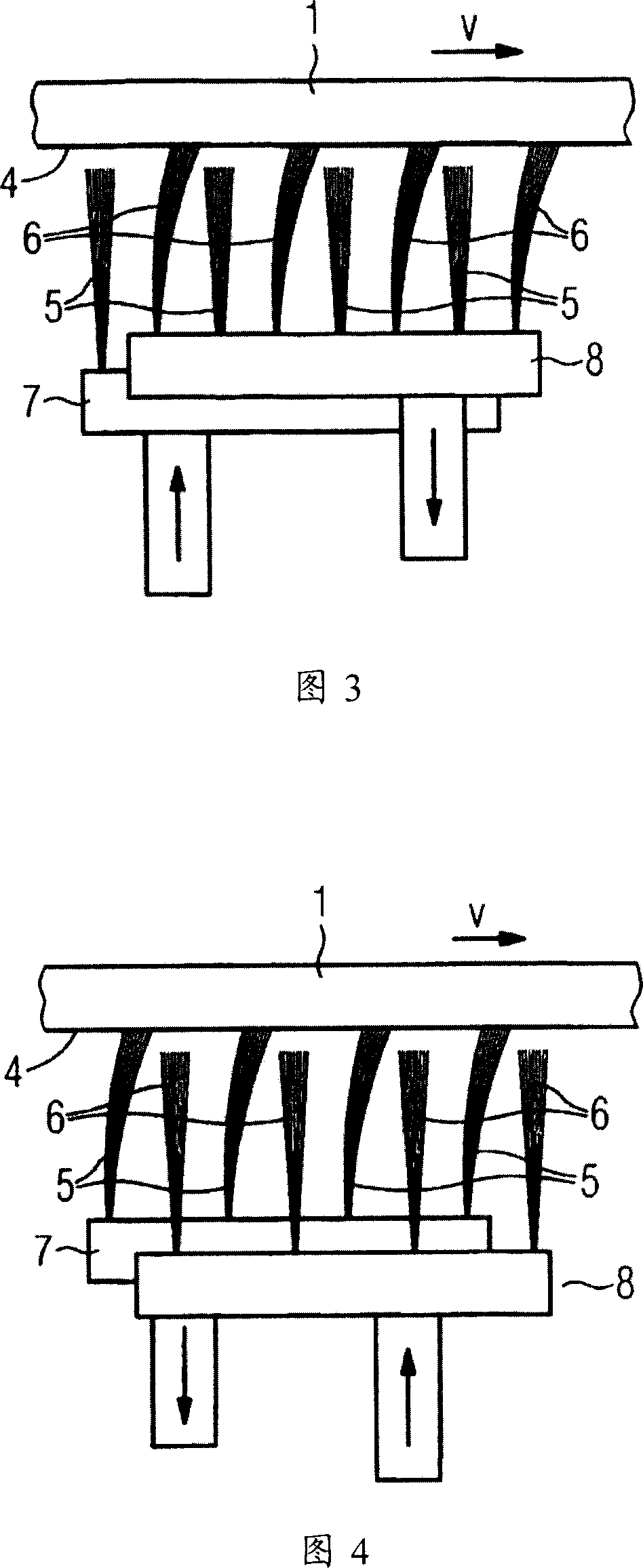

[0027] Figures 3 and 4 show a first embodiment of the device according to the invention. In the described embodiment, an object in the form of a sheet metal 1 is placed on the brush. A first part 5 of the brush is connected to a die 7 . A second part 6 of the brush is connected to a mold 8 . By alternately raising and lowering the first part 5 of the brush and the second part 6 of the brush, these two parts of the brush alternately remain in contact with one surface 4 of the sheet metal. In the first embodiment shown in Fig. 3 and Fig. 4, the alternate ascending and descending of the first part 5 of the brush and the second part 6 of the brush are realized by the alternate ascending and descending of the relatively movable molds 7 and 8. At the point in time shown in FIG. 3 , the first part 5 of the brush is not in contact with the surface of the metal sheet and the second part 6 of the brush remains in contact with the surface of the metal sheet 1 . That is, at the point i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com