Electric cylinder erecting system loading and performance testing device and testing method

A system loading and testing device technology, applied in measurement devices, electrical testing/monitoring, machine/structural component testing, etc., can solve the problems of inability to multi-cylinder synchronous drive reasoning and control performance testing, and achieve convenient and safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

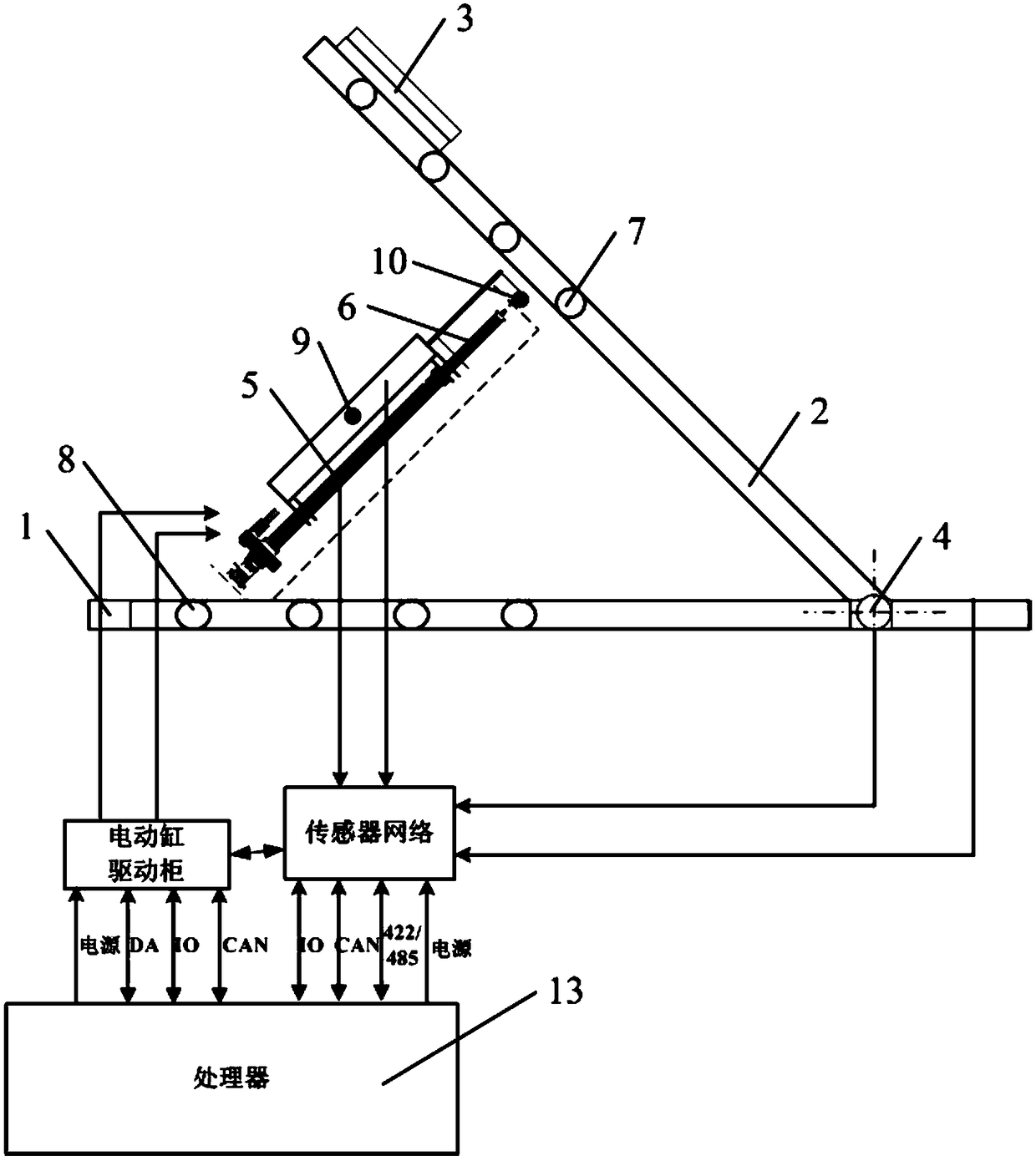

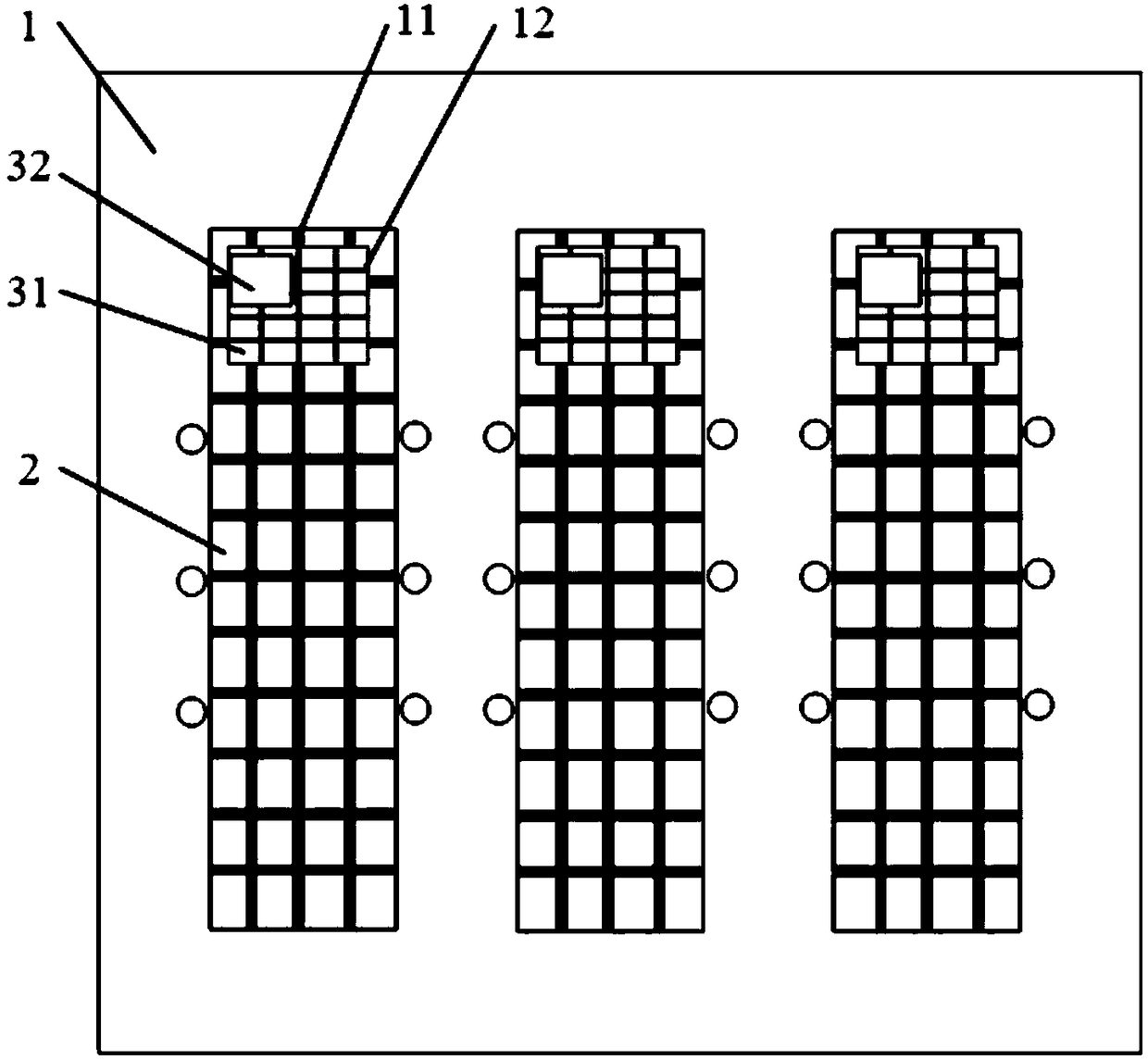

[0033] This embodiment provides a loading and performance testing device for the electric cylinder erecting system, such as Figure 1 to Figure 2 Shown, comprise processor 13 (not shown in the figure), base 1 and multiple groups of test benches positioned on base 1, the structure, shape and size of multiple groups of test benches are all the same, and above-mentioned test bench includes support 2, The movable load 3 on the support 2, a plurality of upper fulcrums 7 slidingly connected with the support 2 and a plurality of lower fulcrums 8 slidingly connected with the base 1, the adjacent supports 2 are detachably and fixedly connected; one end of the support 2 is connected to the base The seat 1 is connected in rotation, and the other end is suspended in the air. An angular displacement sensor 4 is provided at the connection between the bracket 2 and the base 1. The angular displacement sensor 4 is connected to the processor 13; when in use, the cylinder body 5 of the electric ...

Embodiment 2

[0054] This embodiment provides a loading and performance testing method for the electric cylinder erecting system. The electric cylinder erecting system loading and performance testing device provided in the embodiment is used. The above testing method includes the motion accuracy test of a single electric cylinder and the synchronous movement of multiple electric cylinders. Accuracy testing, gravitational loading control of electric cylinders, and active loading control of electric cylinders.

[0055] Specifically, the above-mentioned single electric cylinder motion accuracy test includes the following steps: one of the electric cylinders is disassembled from the other electric cylinders as a test cylinder; the test cylinder is started, the end of the piston rod of the test cylinder is extended outward, and the bracket is lifted , the angular displacement sensor collects the actual rotation angle of the bracket, according to the theoretical elongation value of the piston rod,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com