Roll device

A roller, roller rotation technology, applied in packaging, optics, instruments, etc., can solve the problem of difficult to set accurate conveying position and conveying time, and does not propose that different specifications of film components are attached to different specifications of flat-panel display units. Universal equipment, Unable to set the exact delivery position and delivery time of membrane components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

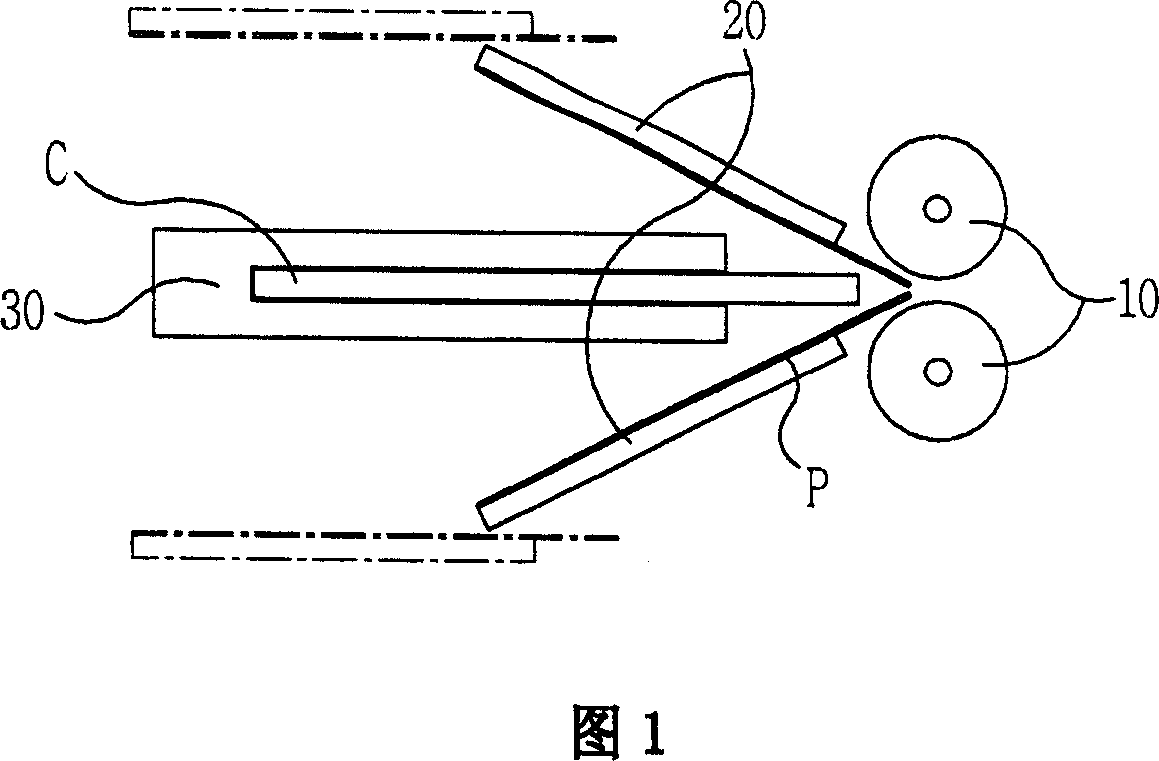

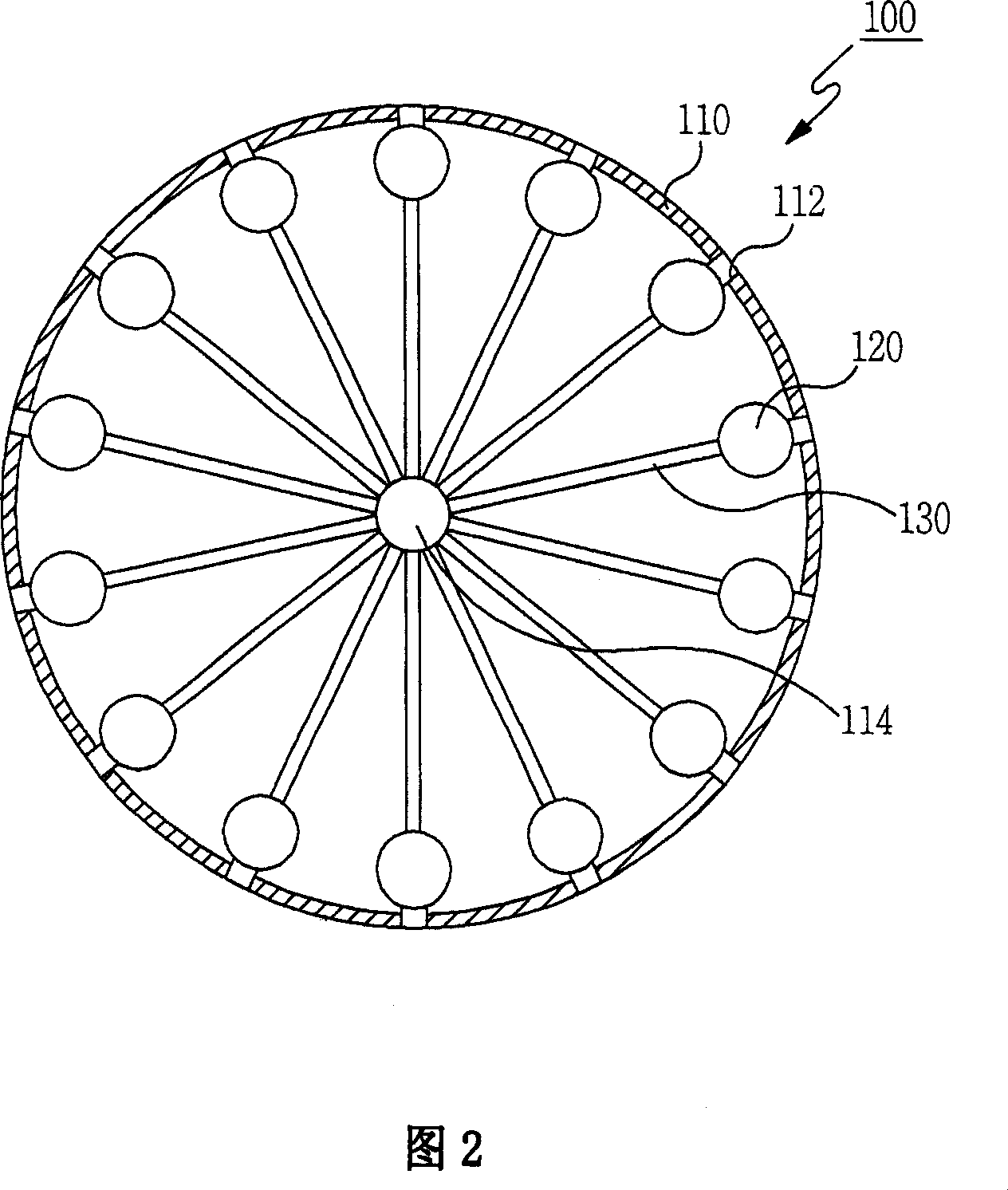

[0032] The features of the roller device according to the present embodiment include that the length of the region in which the vacuum suction force is applied can be varied according to the specifications of the film-like member to be attached. To this end, as shown in FIG. 2, the drum 100 according to the present embodiment includes: an adsorption drum 110; a vacuum pipe 120; a connecting member 130; a vacuum section regulator 140;

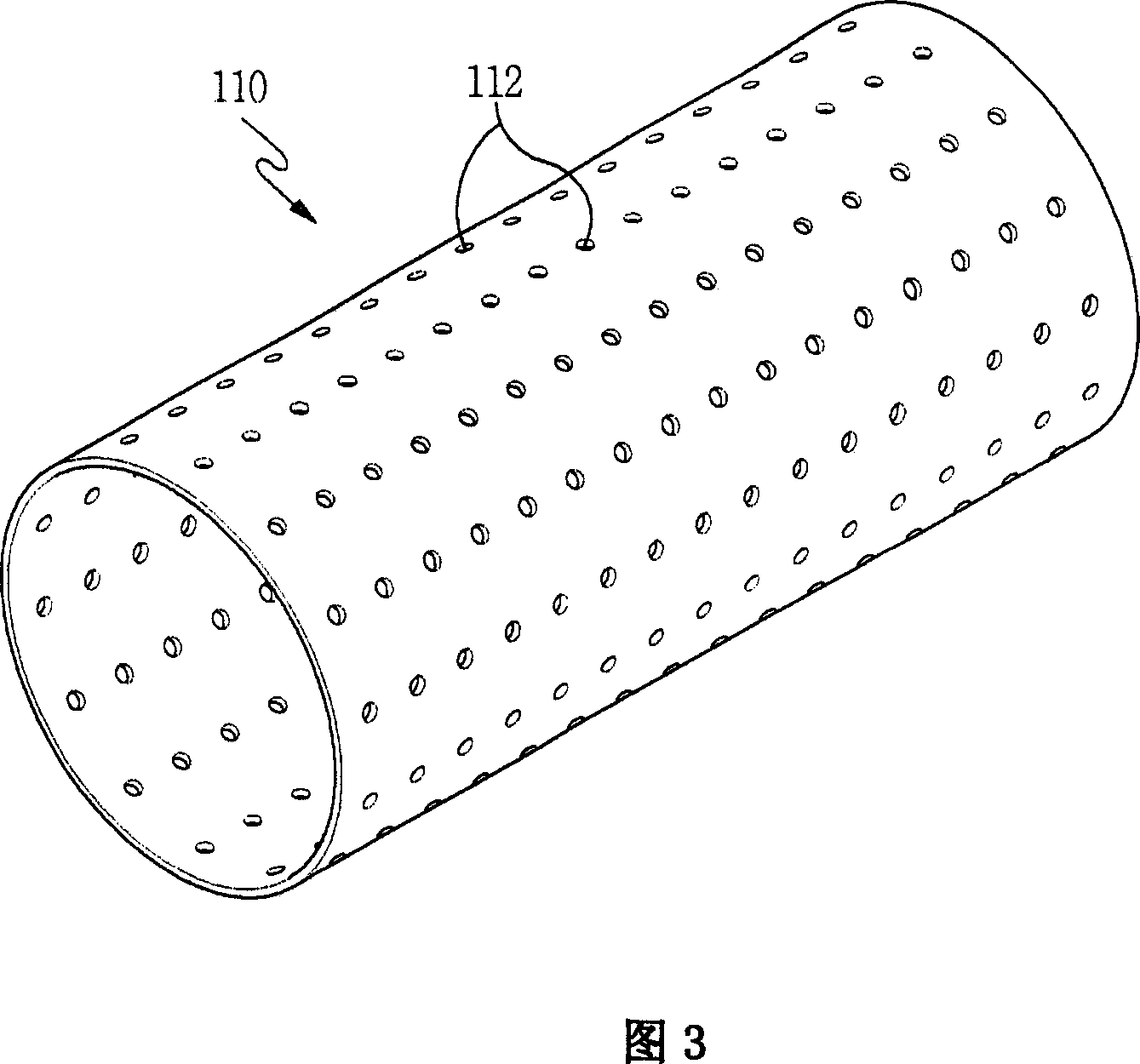

[0033] As shown in FIG. 3, the adsorption roller 110 has a large-diameter cylindrical structure whose circumference is larger than the long side of the conventional largest membrane member. The entire surface of the adsorption roller 110 is punched with a plurality of adsorption holes 112 . Specifically, a plurality of suction holes 112 are uniformly punched on the cylinder having a predetermined thickness to allow the membrane member to be attached to the outer peripheral surface of the cylinder by suction. In this case, it is preferable that ...

no. 2 example

[0047] The features of the roller device 200 according to the present embodiment include that a plurality of vacuum suction sections having different lengths from each other are defined on the outer peripheral surface of the device 200 to correspond to the specification of the membrane member to be attached. For this, as shown in FIG. 7 , the roller device 200 according to the present embodiment includes: a suction roller 210 ; a vacuum pad 220 ; a connection part 230 ; and a roller rotator (not shown).

[0048] Similar to the first embodiment, a plurality of vacuum suction holes 212 are formed on the entire surface of the adsorption roller 210 . The adsorption roller 210 is a constituent element that allows a film member to be attached to its outer peripheral surface.

[0049] A vacuum pad 220 is disposed inside the suction drum 210 to connect with the suction holes 212 . The vacuum pad 220 is a constituent element that applies vacuum suction force to the suction holes 212 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com