Low liquid level quick-break switch device

A technology of quick disconnect switch and low liquid level, applied in the field of low liquid level quick disconnect switch device, can solve the problems of machine damage, reduce the accuracy of controllable liquid level, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

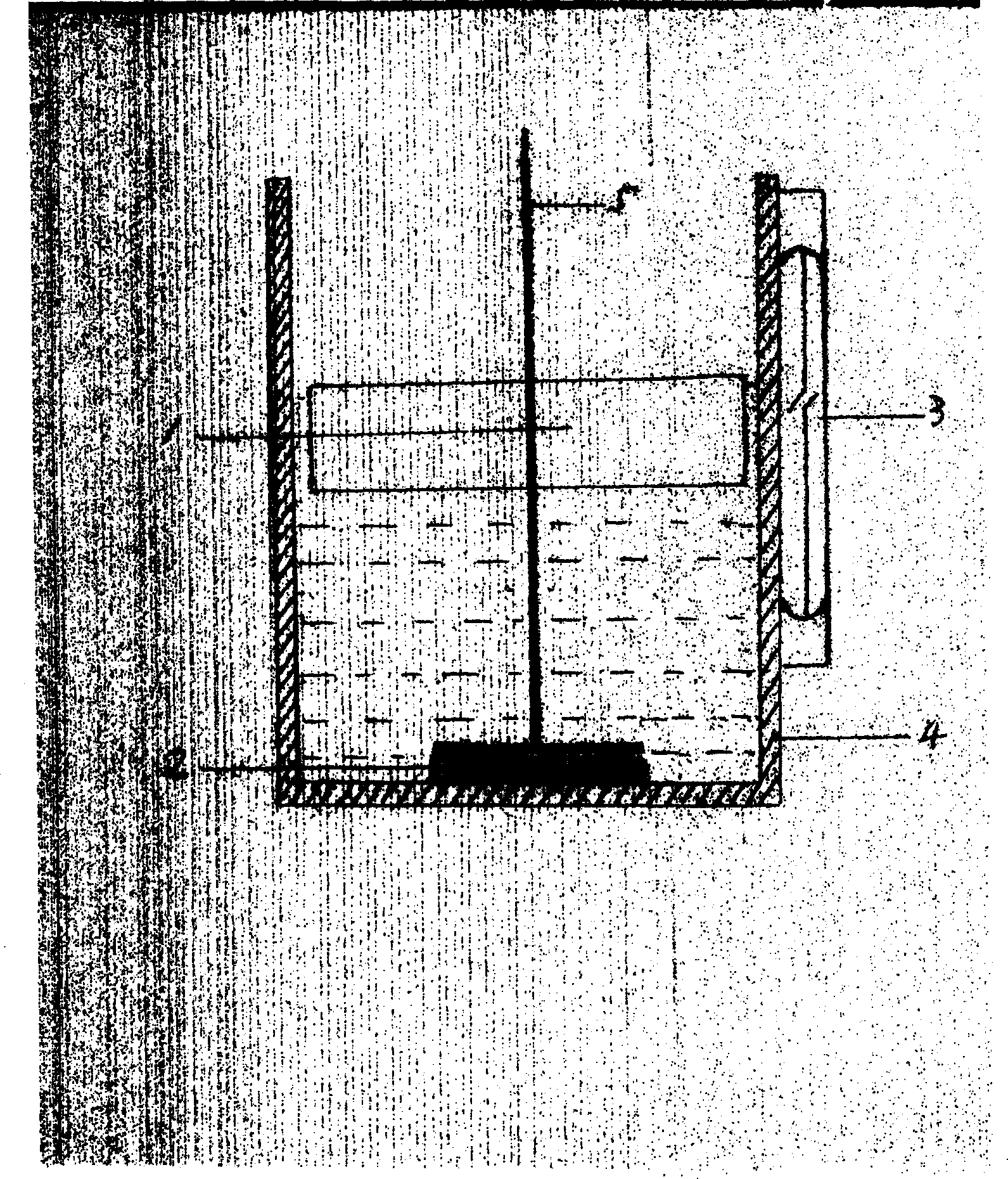

[0007] As shown in the figure, a low-liquid level quick-break switch device is composed of a magnetic float valve 1, a magnetic device 2, an induction switch 3, a liquid container 4, and a pull reset device 5. The above-mentioned induction switch 3 is fixed on the outer wall of the liquid container 4 , no longer immersed in the liquid, and the height of the induction switch can be adjusted at will, so as to achieve the size of the stroke to control the liquid level reduction, and at the same time improve the accuracy of the controllable liquid level; the above-mentioned magnetic float valve 1 and magnetic device 2 are set In the liquid container 4, the magnetic device 2 is located below the corresponding position of the magnetic float valve 1, and is located at the bottom of the liquid container 4. The magnetism of the magnetic float valve 1 is used to induce the induction switch 3 to realize the opening or disconnection of the circuit. When the magnetic float valve 1 drops to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com