Combination spout stop/bottom bushing.

A nozzle and bushing technology, which is applied in the field of faucets, can solve the problems of entanglement of the nozzle pulling out the hose, water spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

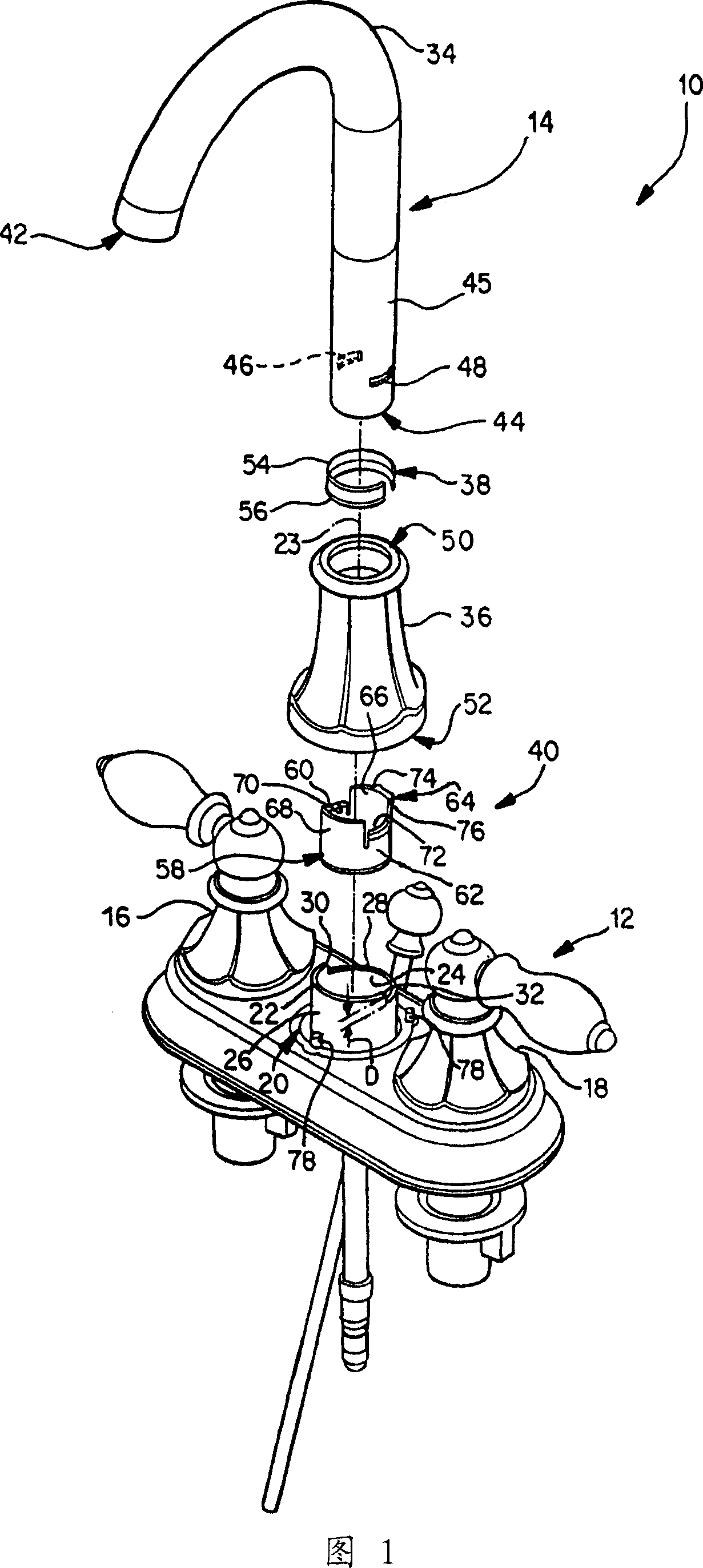

[0015] Referring now to the drawings and in particular to FIG. 1, there is shown a faucet assembly 10 embodying the invention.

[0016] The faucet part 10 includes a faucet housing 12 and a spout part 14 .

[0017] The faucet housing 12 has installed therein a hot water valve part 16 and a cold water valve part 18 . The faucet housing 12 includes a body 20 for rotatably mounting the spout member 14 . The body 20 comprises a cylindrical element 22 with a shaft 23 .

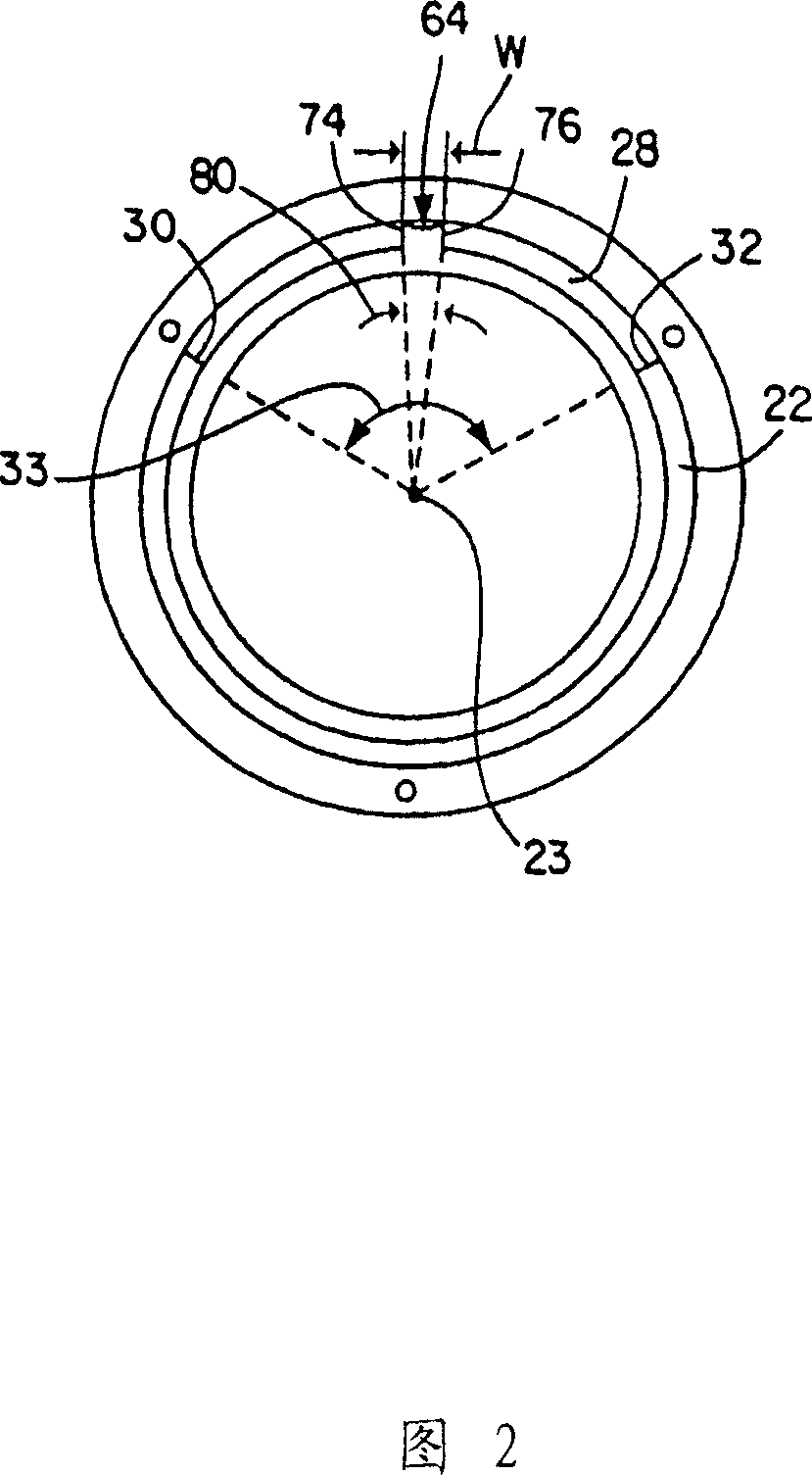

[0018] Referring also to FIG. 2 , cylindrical member 22 includes an inner surface 24 , an outer surface 26 , and an annular passage 28 defining a pair of rotation limiting members 30 , 32 . The annular passage 28 and the rotation limiting parts 30, 32 may be formed in the cylindrical member 22, for example, by removing an annular portion of the cylindrical member 22, thereby forming an incision having a predetermined depth D and providing the rotation limiting parts 30, 32 A predetermined angular distance at an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com