Heavy duty tire

一种轮胎、胎体的技术,应用在特殊轮胎、轮胎零部件、胎沿等方向,能够解决未启示减少滚动阻力等问题,达到能量损耗降低、防止耐久性劣化、减少滚动阻力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13 and comparative example 1~5

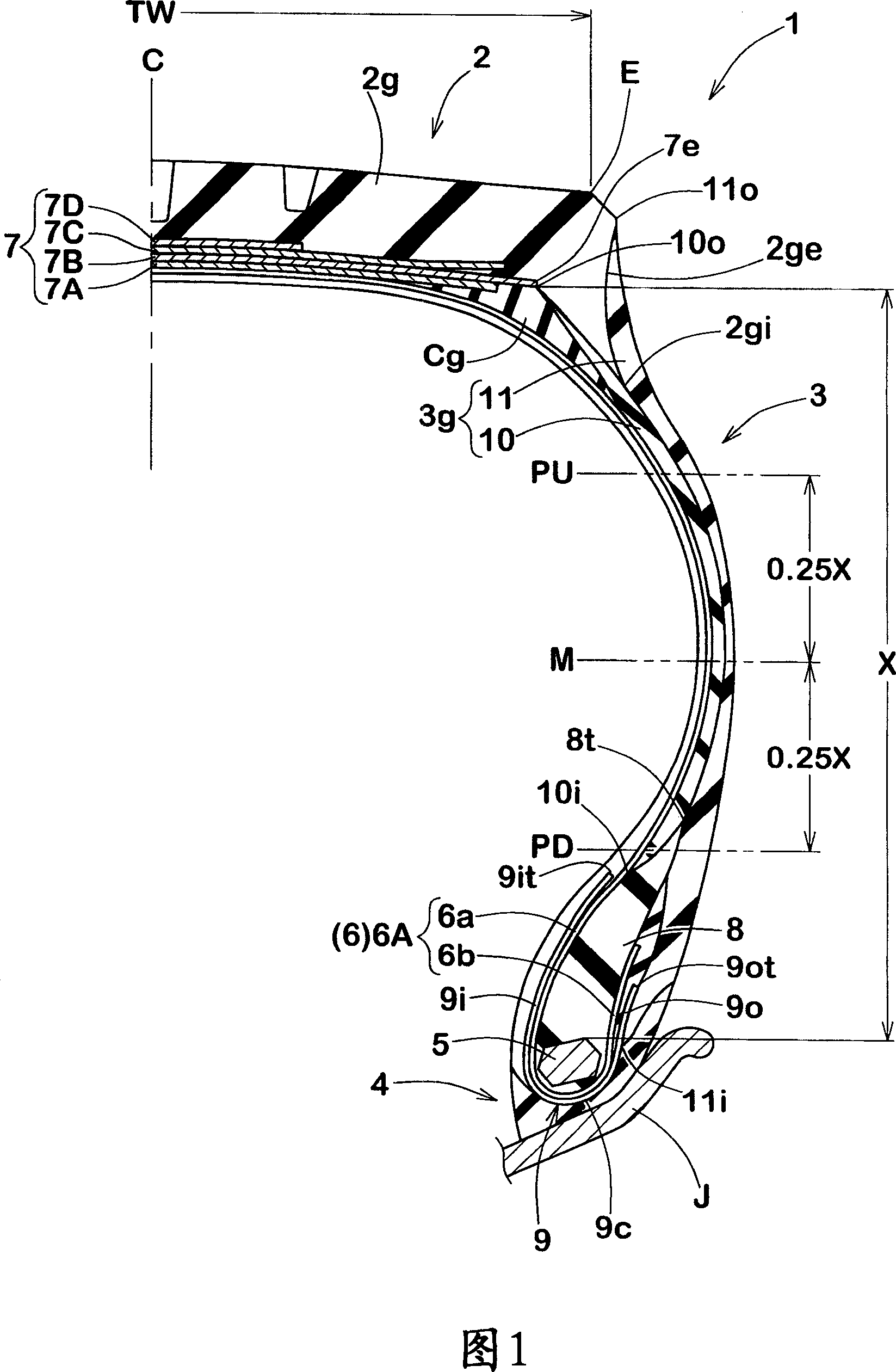

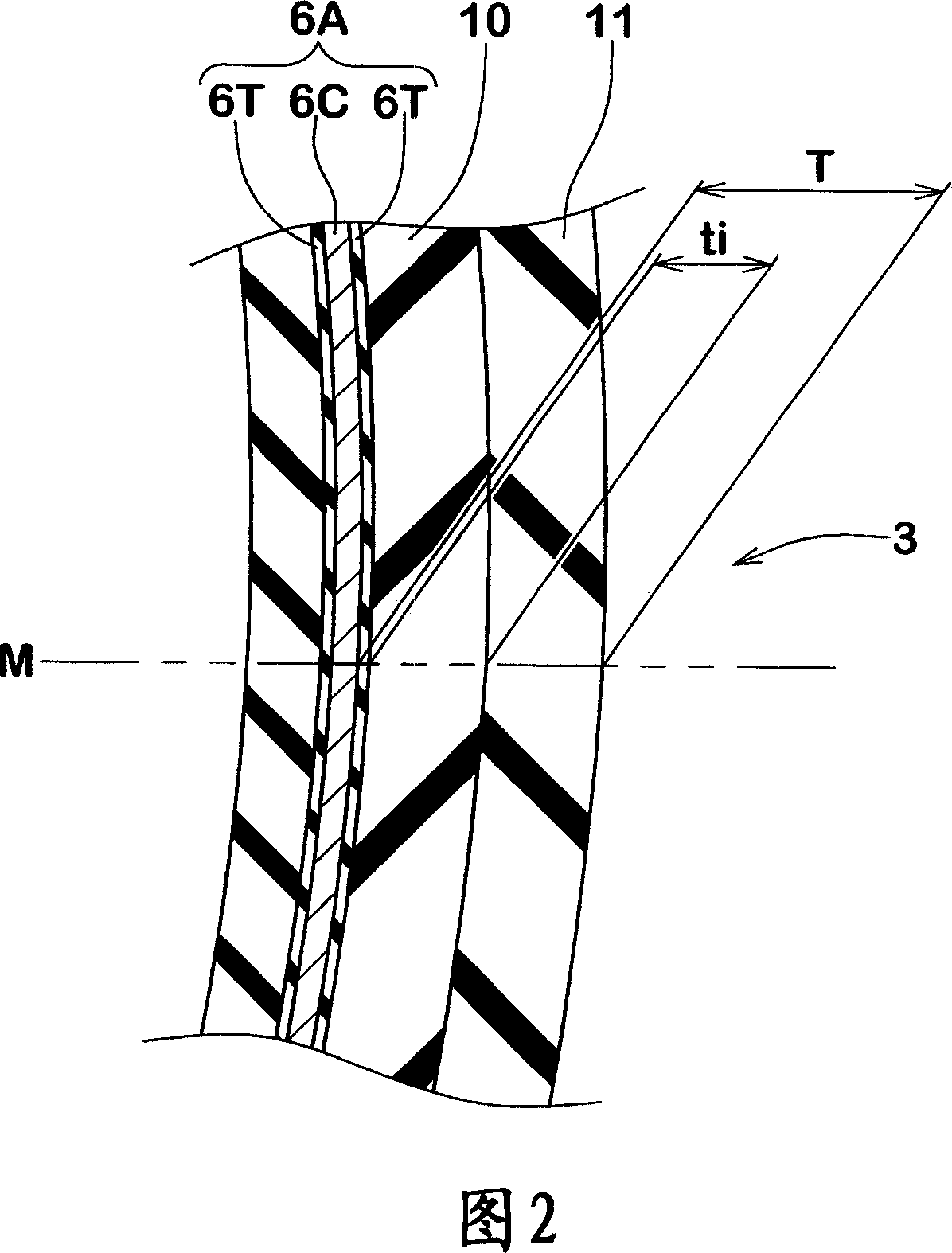

[0044] A truck tire (size: 11R22.5 14PR) having the basic structure shown in FIG. 1 was manufactured according to the specifications shown in Table 1, and its rolling resistance and durability were measured by the method described below. The tire specifications not described in the table are the same for all tires. The radial distance X of the tire from the axially outer end 7e of the belt layer 7 to the radially outer surface of the bead core 5 is 180 mm.

[0045]

[0046] The tire was run using a rolling resistance meter under the condition of a rim of 7.50×22.5, an internal pressure of 700 kPa, a speed of 80 km / h, and a tire load of 24.52 kN, and the rolling resistance was measured. The result is shown with the result of Comparative Example 1 as an index of 100. The smaller the value, the better the scrolling characteristics.

[0047]

[0048]An incision with a length of 5 mm and a depth of 3 mm is formed at the midpoint position M in the sidewall part, and the drum of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com