Systems and methods for forming integrated circuit components having precise characteristics

A technology of integrated circuits and components, which is applied in the system field of integrated circuit components, can solve the problems of increasing the cost of integrated circuit devices, increasing cycle time and manpower, and reducing efficiency, so as to achieve the effects of reducing cycle time, increasing production, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

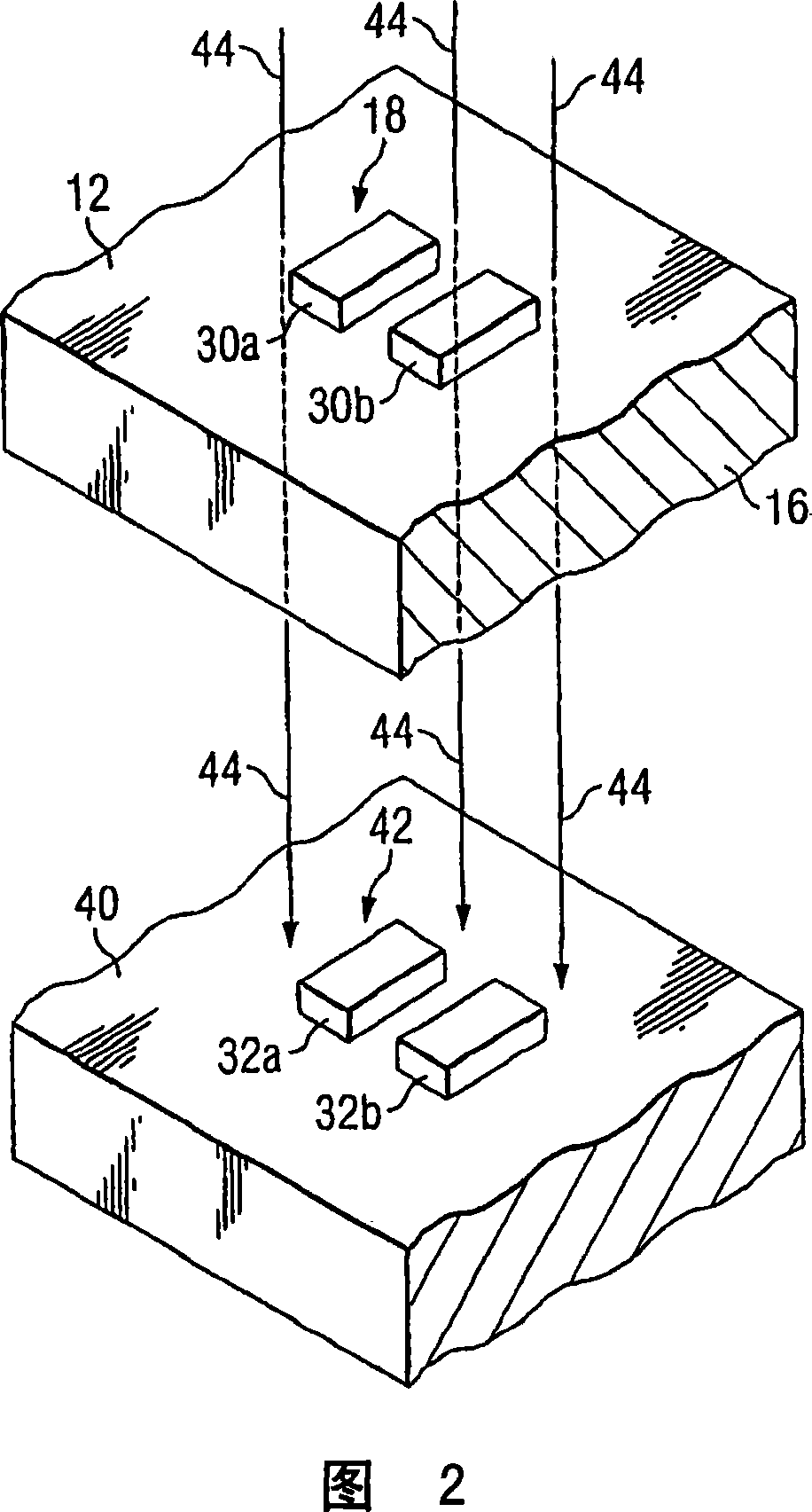

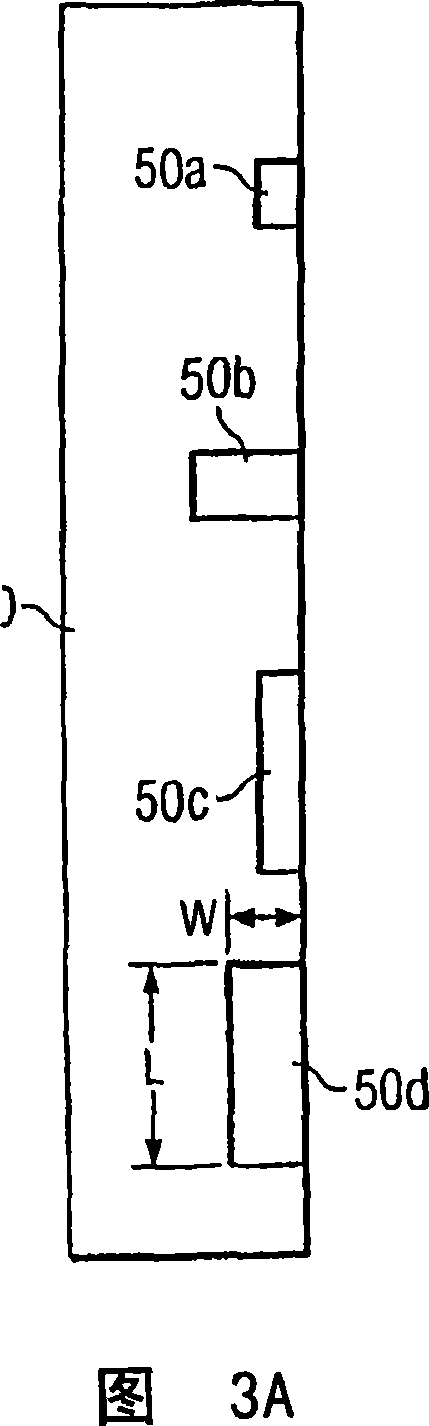

[0018] Preferred embodiments of the present invention and their advantages are best understood by referring to FIGS. 1 through 6, wherein like numerals are used to indicate like and corresponding parts.

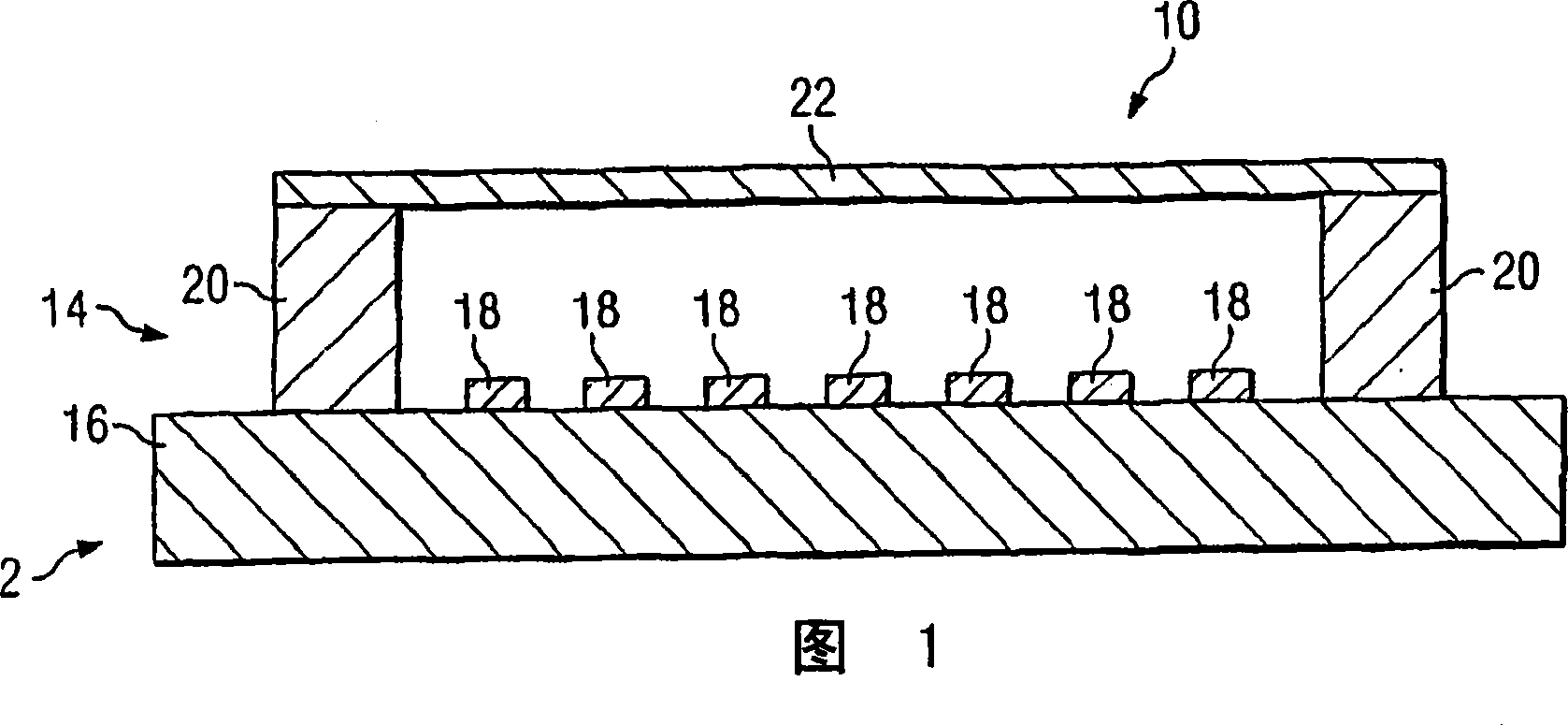

[0019] Figure 1 illustrates a cross-sectional view of an example photomask assembly 10 in accordance with certain embodiments of the invention. Photomask assembly 10 may include a pellicle assembly 14 mounted on photomask 12 . Substrate 16 and patterned layer 18 may form photomask 12, otherwise referred to as a mask or reticle, which may have a variety of sizes and shapes including, but not limited to, circular, rectangular, or square, for example. The photomask 12 can also be any of a variety of photomask types including, but not limited to, a primary master, a five-inch reticle, a six-inch reticle, a nine-inch reticle, or a projected image of a circuit pattern to any other appropriately sized reticle on a semiconductor wafer. The photomask 12 can also be a binary mask, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com