Body warp, warp letting off device of towel rapier loom

A technology of rapier looms and wool warp yarns, applied in looms, velvet looms, textiles, etc., to achieve the effects of improving cloth surface quality and loom efficiency, reducing resistance, and improving the rate of first-class products off the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

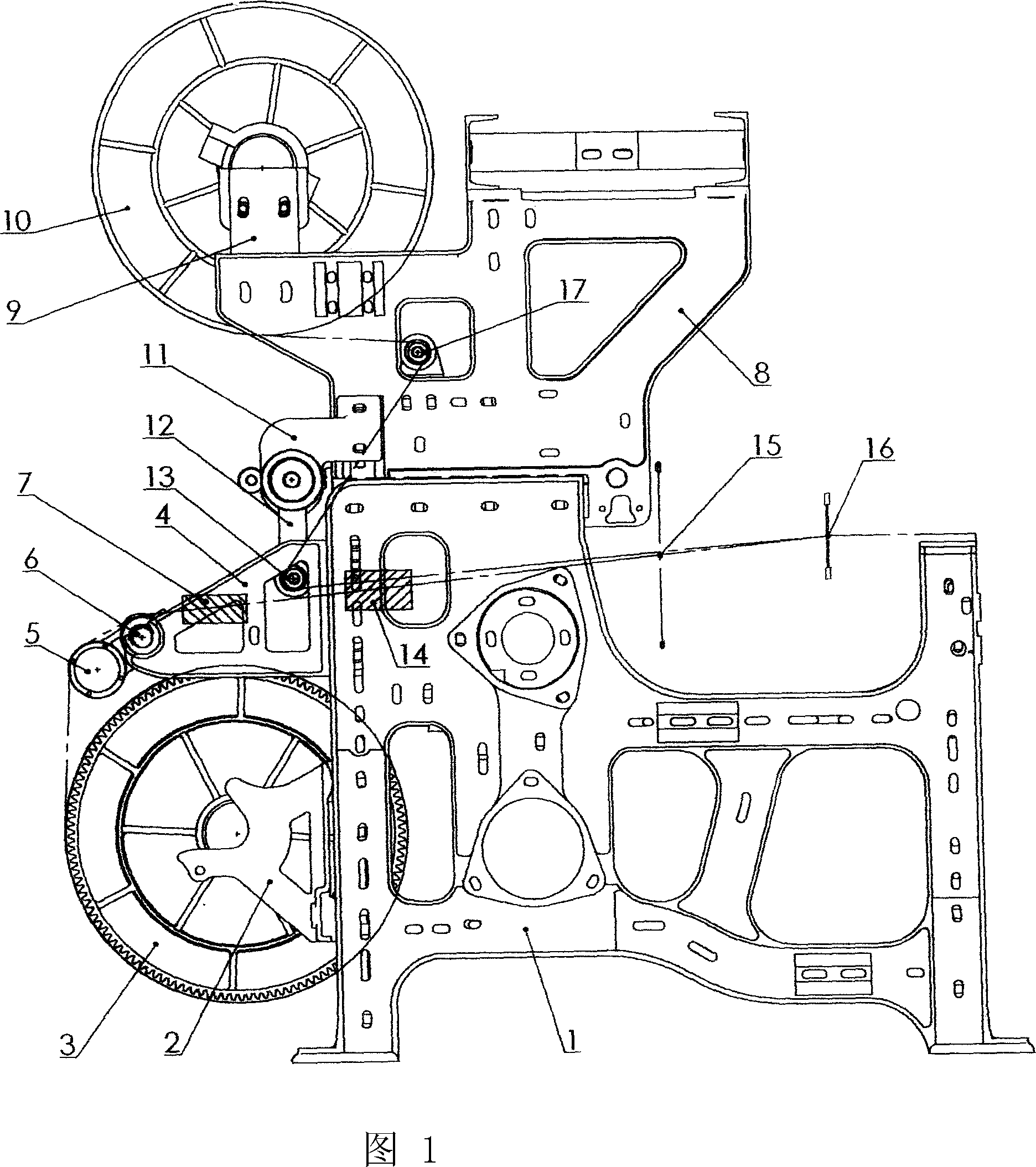

[0018] The warp breakage self-stop protection mechanism of the towel rapier loom includes a large wallboard 1, a bottom warp shaft support 2, a bottom warp shaft 3, a back beam support 4, a bottom warp tension roller 5, and a rear bar 6 , small wallboard 8, heightening wool warp beam support 9, wool warp beam 10, swing arm support 11, swing arm 12, wool warp yarn tension roller 13, heddle eye 15, weaving mouth 16, wool warp beam 10 passes through to increase Wool warp beam supporting foot 9 is fixed on the small wallboard 8, is provided with woolen warp thread guide roller 17 between woolen warp beam 10 and woolen warp yarn tension roller 13, is provided with between rear bar 6 and woolen warp yarn tension roller 13 Bottom warp yarn electronic warp stop device 7; wool warp yarn electronic warp stop device 14 is arranged between wool warp yarn tension roller 13 and heald eye 15, and bottom warp yarn electronic warp stop device 7 is installed on the back rest support foot 4; wool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com