Method and machine for changing agricultural mulch

a technology for agricultural mulch and machines, applied in the field of agricultural mulch change machines, can solve the problems of difficult removal of used film, high labor intensity, and high cost of disposal of used film, and achieve the effects of saving time, effort, and expense, and extending the useful life of partially degraded film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

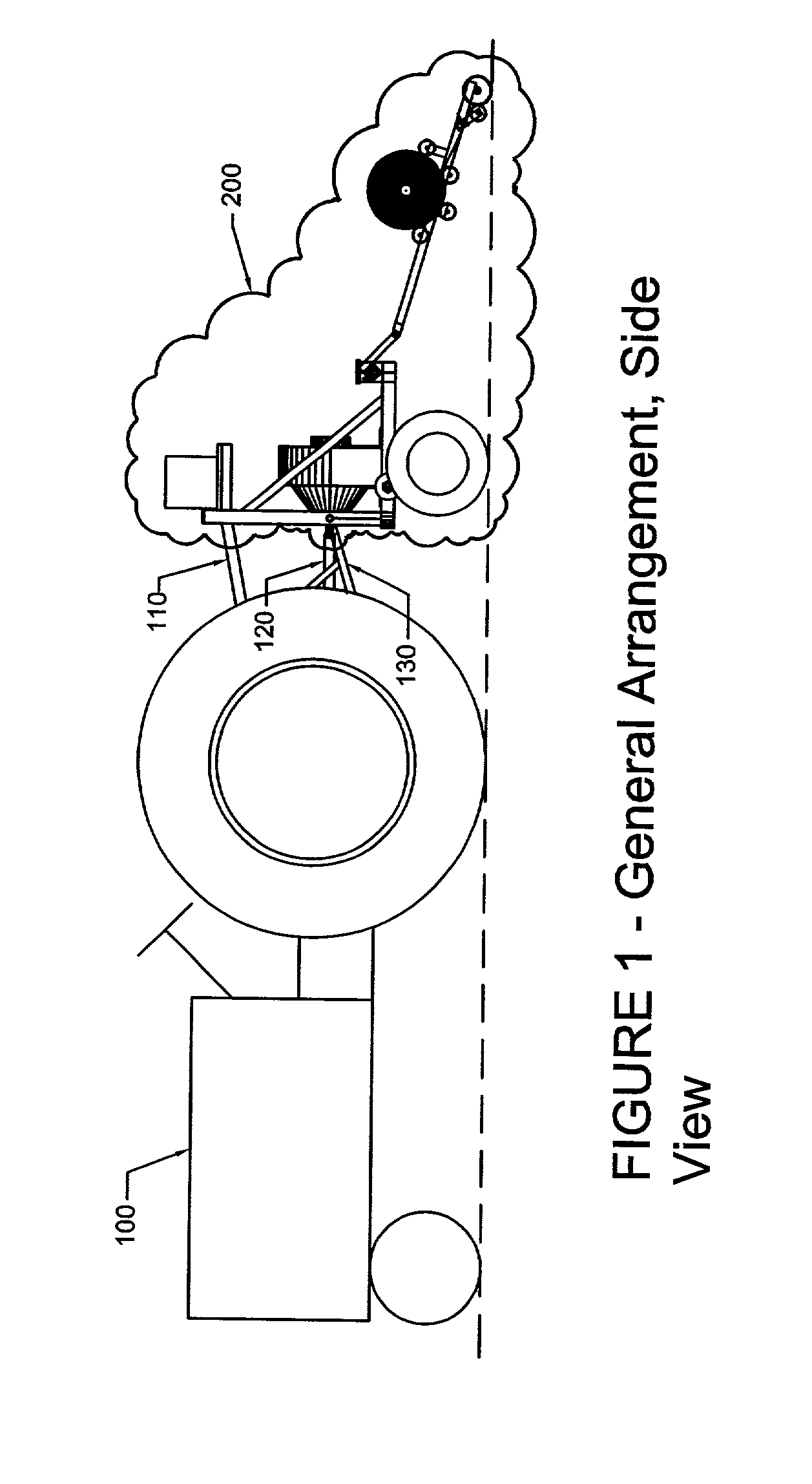

[0066] FIG. 1 illustrates the Field Plastic Laminating Machine 200 attached to a farm tractor 100 using the 3-point hitch top arm 110 and the 3-point hitch bottom arms 130. The blower drive (either tractor hydraulic or tractor power take-off) is connected to the tractor FIG. 1 illustrates the connection of a power take-off universal shaft 120 to the pressure blower input shaft 225.

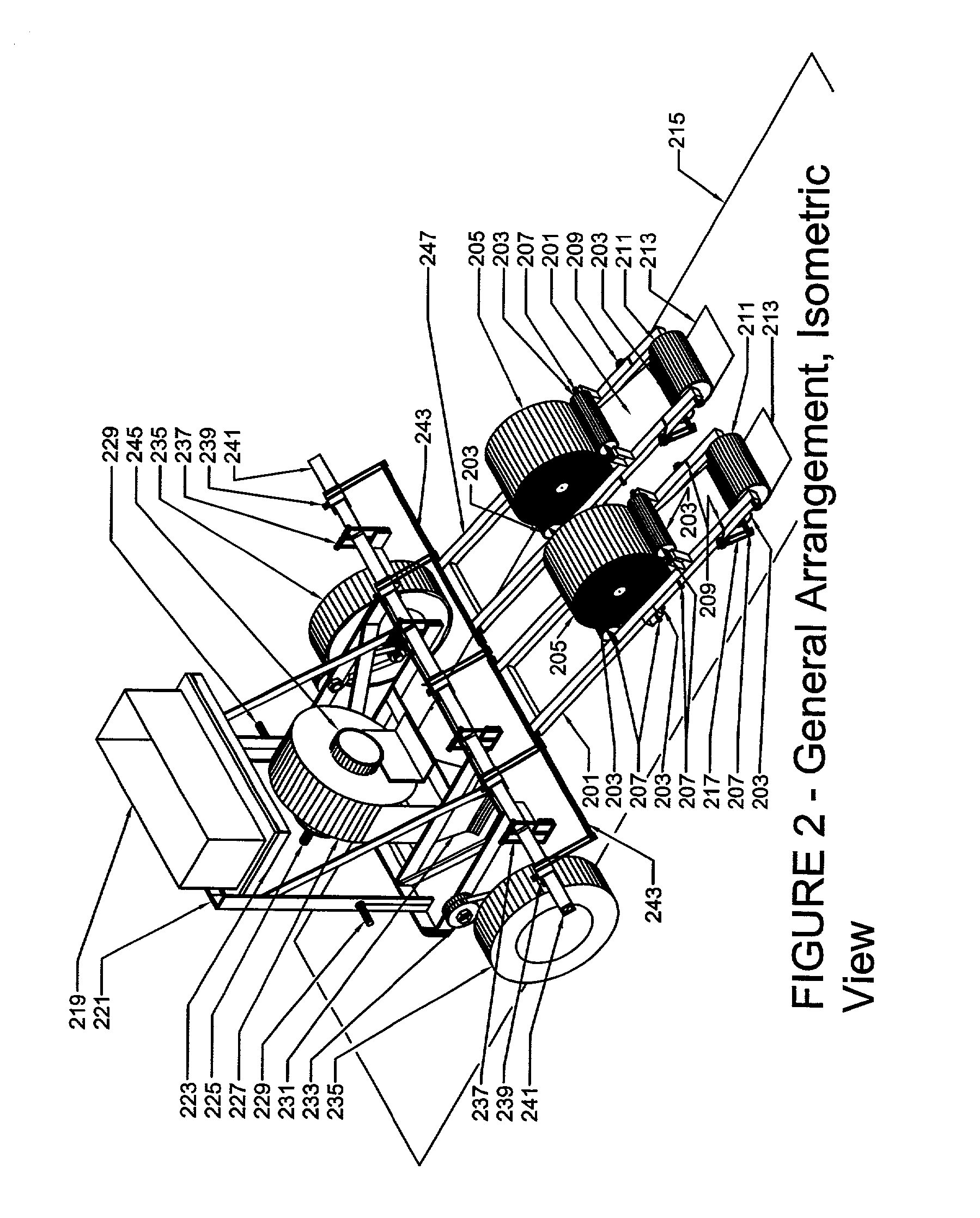

[0067] The significant machine components illustrated in FIG. 2 are the carrier frame 221 which is an industry standard welded fabrication of hot rolled structural steel shapes and forged steel hitch pins 229 with rubber tire, rim and axle 235 mounted on an adjustable height wheel mount 233; the toolbar 241 that is attached to the carrier frame by mounts 237; the carrier swivel rod 243 attached to the toolbar 241 by adjustable toolbar clamps 239, the pressure blower 227, attached pressure blower outlet nozzle 231 and attached pressure blower inlet 245. and the film roll stock carrier frame attached to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap