Heat energy recycling device for producing biogas by waste heat and operating mode thereof

An operation mode, biogas technology, applied in biological sludge treatment, waste fuel and other directions, can solve the problems of consuming large heat energy, polluting the environment, aggravating the greenhouse effect, etc., to reduce operating costs, save heat energy, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

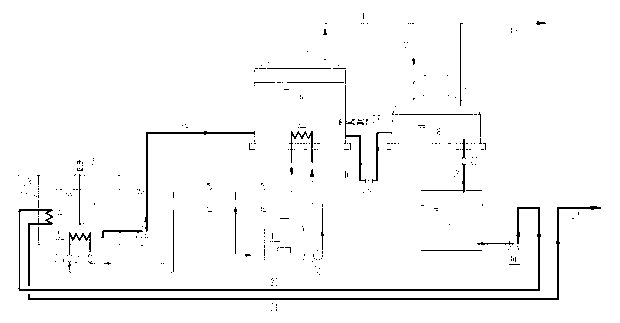

[0030] Such as figure 1 As shown, a thermal energy recycling device for producing biogas by using waste heat and its operation mode are characterized in that the device is composed of a raw material blending pool 1, a raw material blending pool mixer 2, a raw material pump 3, a primary raw material heater 4, and a secondary raw material Heater 5, anaerobic fermentation tank 6, anaerobic tank heater 7, secondary fermentation tank and gas storage tank 8, biogas residue biogas slurry pool 9, biogas residue biogas slurry delivery pump 10, hot water boiler 11, hot water circulation Pump 12, raw material delivery pipeline 13 from raw material blending tank to anaerobic fermentation tank, hot water supply pipeline 14, hot water return pipeline 15, biogas residue transported from anaerobic fermentation tank to secondary fermentation tank and gas storage tank The biogas slurry delivery pipeline 16, the pipeline 17 for introducing the biogas produced by the anaerobic fermentation tank i...

Embodiment 2

[0032] Such as figure 1 As shown, the positional relationship of each component of a thermal energy recycling device that utilizes waste heat to produce biogas is as follows: the raw material inlet 23 is on the upper part of the raw material blending pool 1, and is used to send raw materials into the raw material blending pool 1; the primary raw material heater 4 , installed on the wall of the raw material blending pool 1 in a suspended manner, is a high-temperature biogas residue and biogas slurry heater; the secondary raw material heater 5, in the raw material blending pool 1, is a hot water heater; the raw material blending pool mixer 2, in The raw material blending pool 1 plays the role of blending and stirring.

[0033] The high-temperature biogas residue biogas slurry delivery pipeline 20 is a delivery pipeline connecting the biogas residue biogas slurry tank 9 and the primary raw material heater 4, and transports the 35°C high-temperature biogas residue biogas slurry fr...

Embodiment 3

[0039] Such as figure 1 As shown, the operation mode of a thermal energy recycling device that utilizes waste heat to produce biogas is as follows:

[0040] (1) Open the discharge valve 22 of the secondary fermentation tank, and discharge the biogas residue and biogas slurry at a high temperature of 35°C in the secondary fermentation tank and the gas storage tank 8 to the biogas residue and biogas slurry tank 9 . When the liquid level of the secondary fermentation tank and the gas holder 8 reaches a suitable low level, close the discharge valve 22 of the secondary fermentation tank and stop discharging.

[0041] (2) Open the discharge valve 26 of the anaerobic fermentation tank, and discharge the biogas residue and biogas slurry at a high temperature of 35°C to the secondary fermentation tank and the gas storage tank 8, so that the liquid level of the secondary fermentation tank and the gas storage tank 8 reaches a high level, Close the anaerobic fermenter drain valve 26. At...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap