Bender stand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

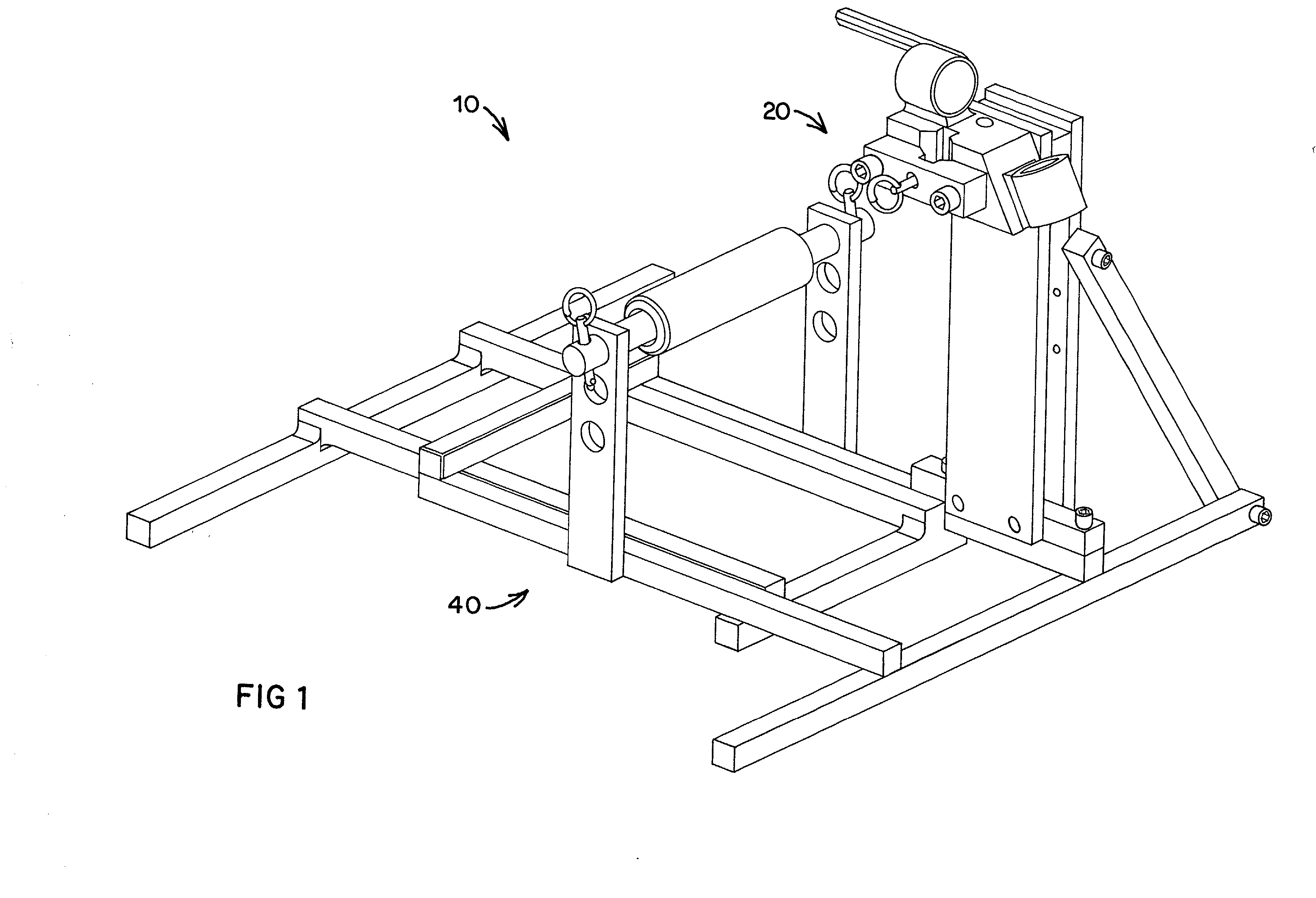

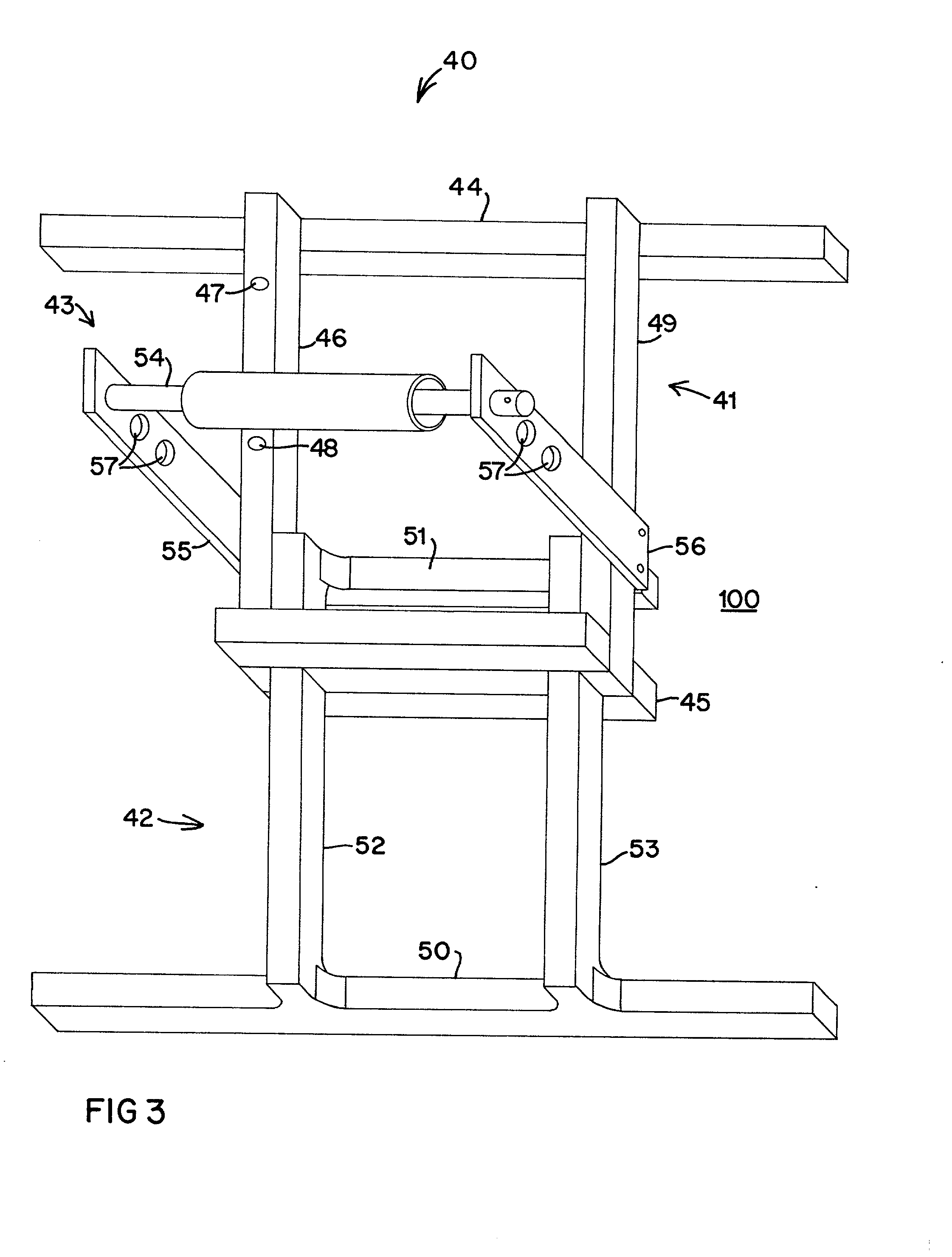

[0023] A bender stand 10 of the present invention is shown in FIG. 1 and includes a bender securing assembly 20 and a base 40. In addition, details of the bender securing assembly 20 are shown in FIG. 2 and details of the base 40 are shown in FIG. 3. The bender stand 10 includes the bender securing assembly 20 connected to the base 40 so that a user may conveniently bend conduit using a hand bender and without jury-rigging a support to keep the conduit in position for accurate bending.

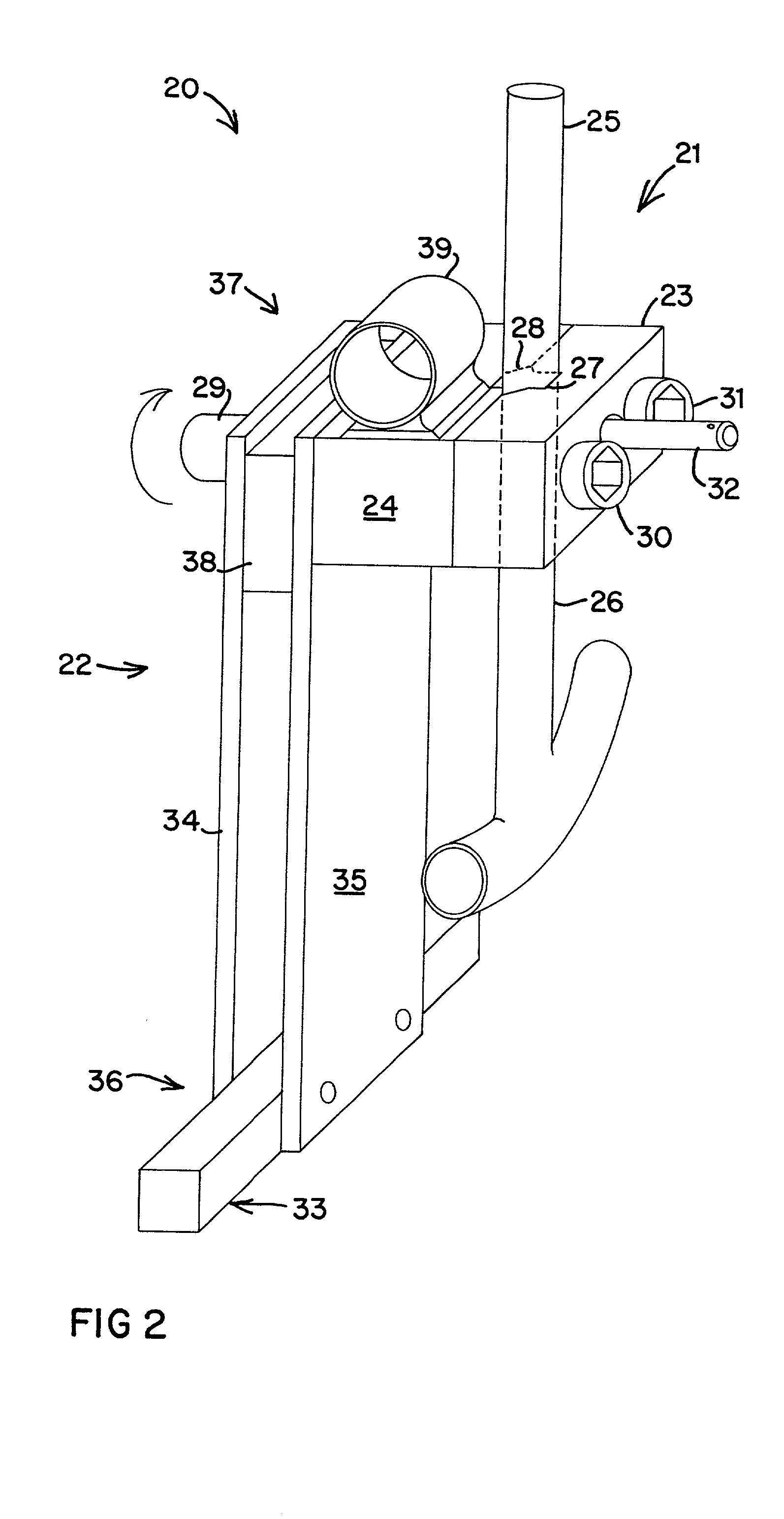

[0024] With reference to FIG. 2, the securing assembly 20 includes a rotatable bender securing frame 21 and a support frame 22. The securing frame 21 includes a first securing block 23 and a second securing block 24 for securing a handle 25 of a hand bender 26 therebetween. The first securing block 23 preferably includes a first V-notch 27 and the second securing block 24 preferably includes a second V-notch 28 therein for fixing the position of the handle 25 once the bender 26 is positioned at a desir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com