Chemico-mechanical microvalve and devices comprising the same

a micro-fluidic and mechanical technology, applied in chemical/physical/physico-chemical microreactors, optical light guides, fluid speed measurement, etc., can solve the problems of inability to control the valve, significant technical obstacles to overcome, and control of fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

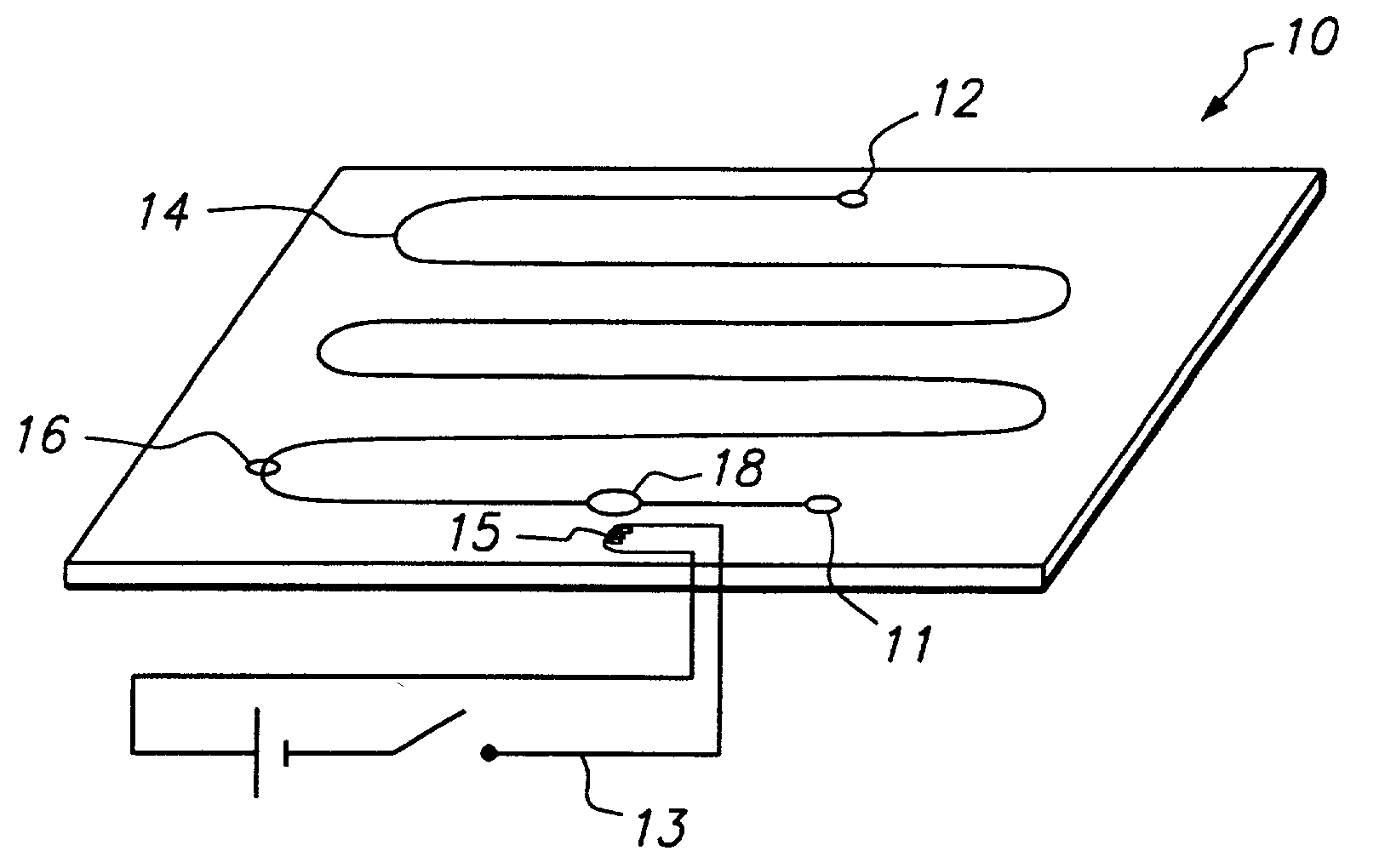

first embodiment

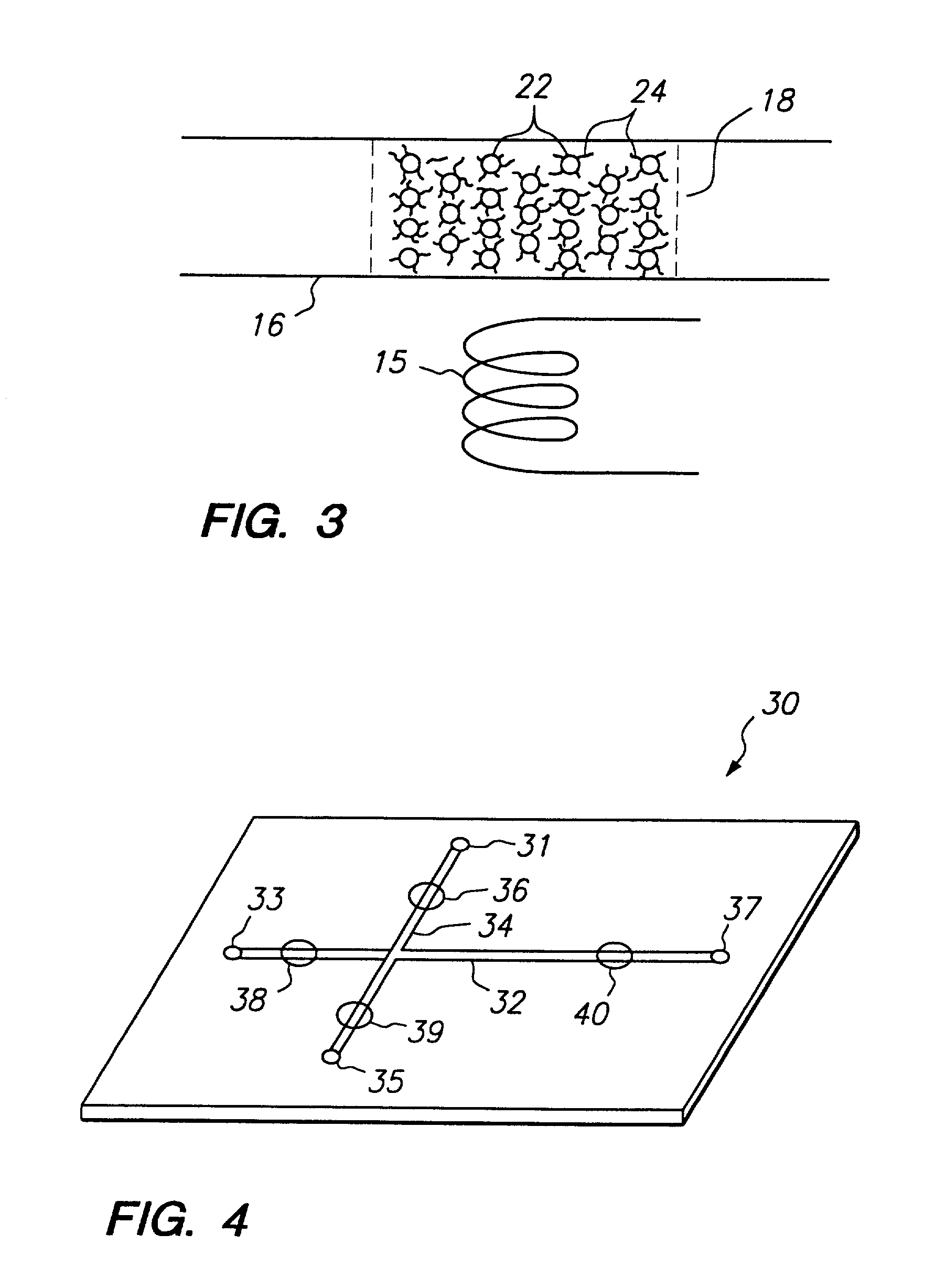

[0036] In the subject invention, the micro-valve is made solely of the phase reversible material. In this embodiment, the phase reversible material may be positioned at one or more distinct locations along the fluid flow path, or along substantially the entire fluid flow path. Where the phase-reversible material occupies substantially the entire fluid flow path, during use its phase is generally switched from a fluid permeable to a fluid impermeable state at one or more distinct locations along the fluid flow path, but not along the entire fluid flow path.

[0037] In a preferred structure of the this first embodiment, the micro-fluidic device contains at least two intersecting flow paths, one of which is substantially filled by the phase reversible material. In other words, the device includes at least a main flow path and at least one intersecting second flow path, where substantially all of the secondary flow path is occupied by the phase reversible material. By "substantially all" ...

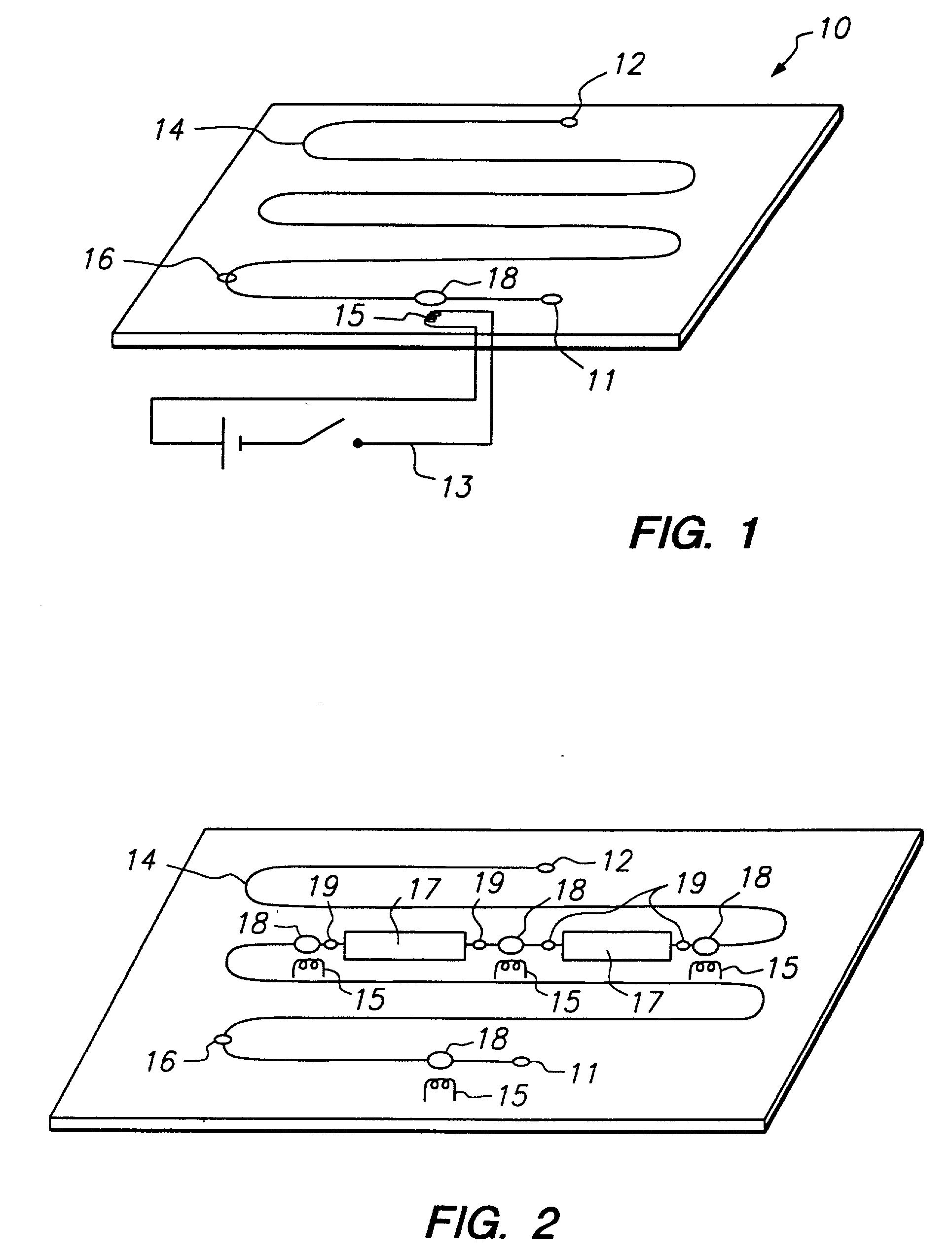

second embodiment

[0039] In these embodiments where the micro-valve consists essentially of the phase reversible material, the phase reversible material will be stably associated with the region of the device in which fluid flow modulation is desired. Stable association may be achieved in a number of ways, including bonding, and the like. In many embodiments, the phase reversible material may be bonded directly to the region of interest of the micro-fluidic device, where the nature of the bond may be covalent or non-covalent. For example, where the phase reversible material is a polymeric gel, the polymeric constituents of the phase reversible material may be bonded directly to the micro-compartment wall of the device in the region in which valve fluid control is desired, where the nature of the bond may be covalent or non-covalent, but will usually be covalent. The length of the micro-compartment occupied by the micro-valve in this second embodiment, i.e. the length of the micro-compartment to which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micro-volume | aaaaa | aaaaa |

| micro-volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com