Oxide superconductor thick film and method for manufacturing the same

Inactive Publication Date: 2004-06-10

DOWA ELECTRONICS MATERIALS CO LTD +1

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, even with the high Jc attained by using such compressing operation, when a substantial cross-sectional area of the thick film on which the superconducting current flows was small, an adequate net value of the superconducting current cannot be attained, and thus it is not suitable for practical use.

In the above-described method of forming a Bi2223 thick film related to the pr

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

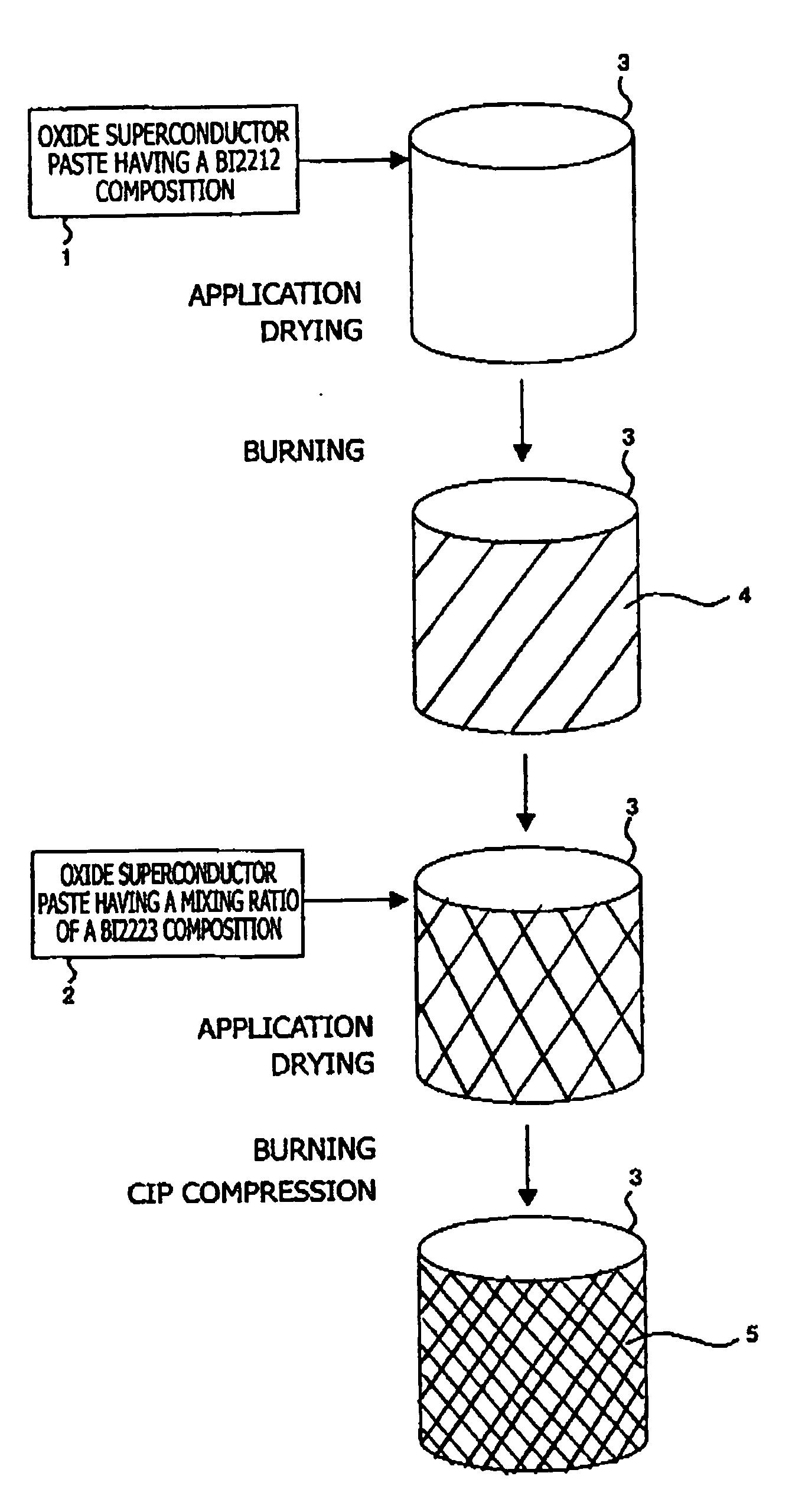

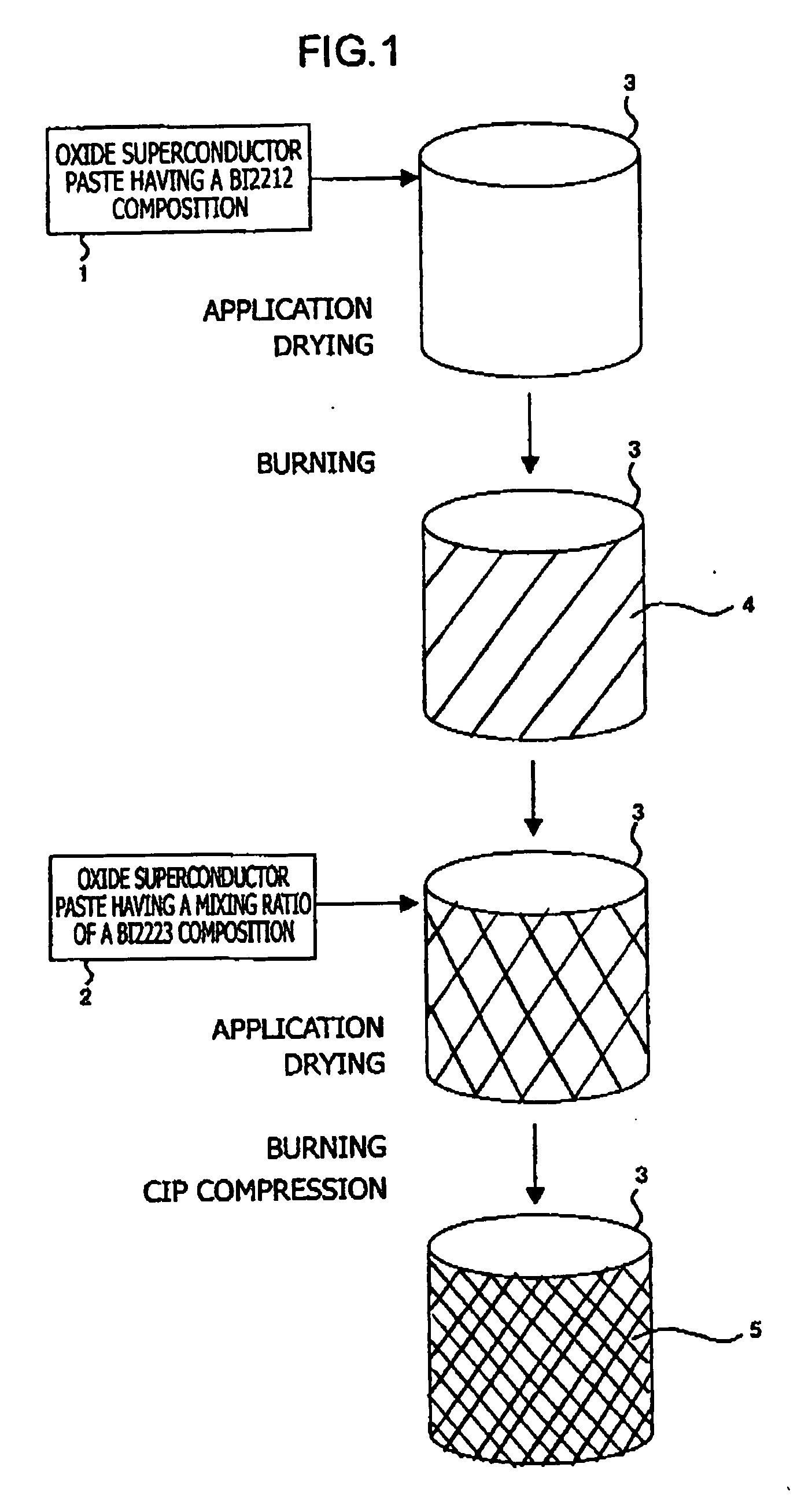

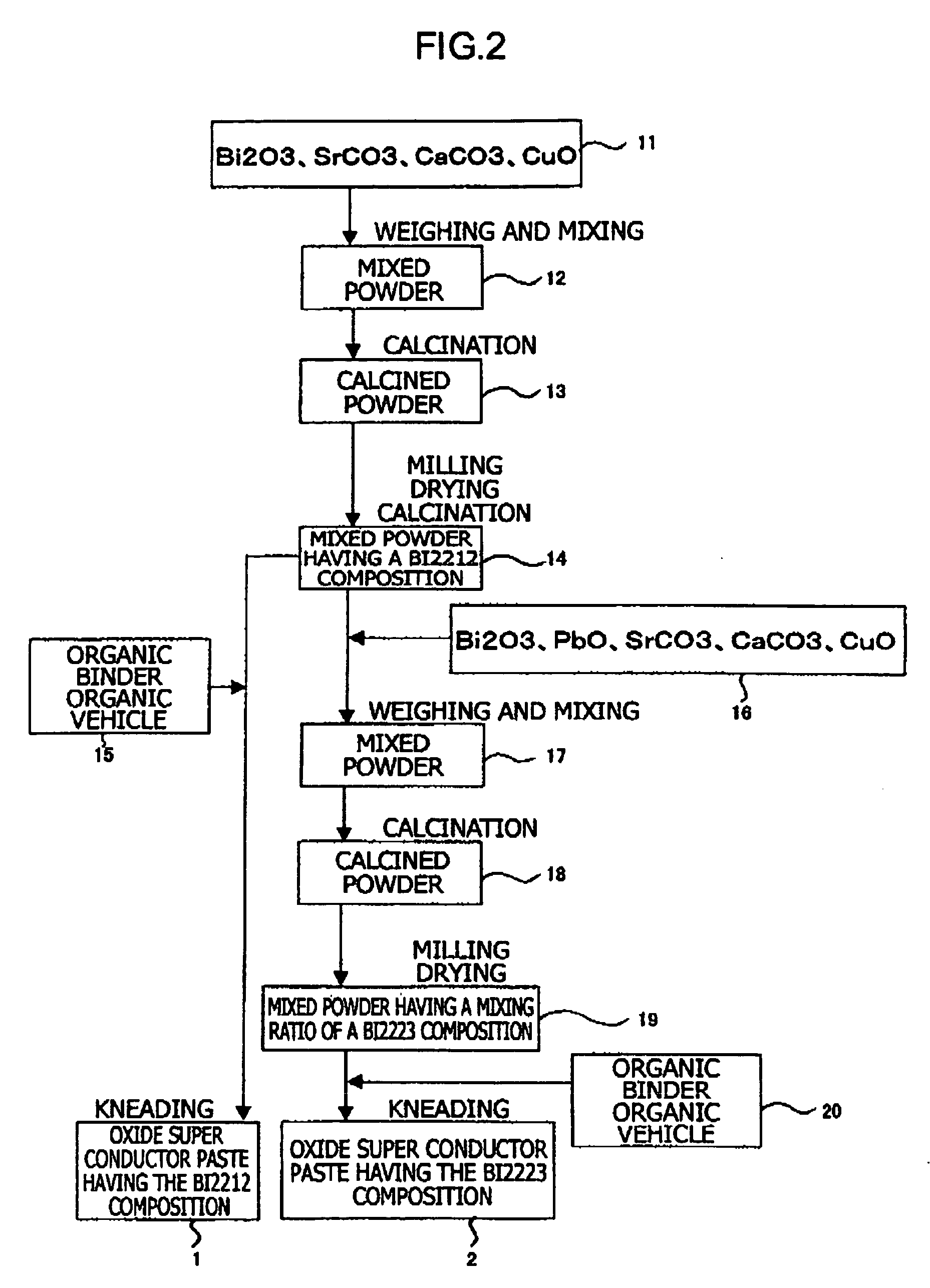

The present invention provides a Bi2223 based thick film that does not peel off when a thermal or a mechanical shock is applied to a base or an oxide superconductor thick film or the like in the middle of a manufacturing process and a method of manufacturing the same An oxide superconductor paste 1 having a mixing ratio of Bi2212 composition is applied to a base 3, dried, burned, and thereafter burned at a temperature approximate to its melting point to obtain a partially molten layer 4. Next, an oxide superconductor paste 2 having a mixing ratio of Bi2223 composition is applied to the partially molten layer 4, dried, burned, compressed by a CIP, and thereafter repeatedly burned and compressed for a predetermined number of times to obtain the base 3 having a desired superconductor thick film 5 formed thereon.

Description

[0001] 1. Field of the Invention[0002] The present invention relates to an oxide superconductor thick film containing Bi, Pb, Sr, Ca and Cu having a high critical current density and a high adhesiveness to an oxide substrate or an oxide base, and a method for manufacturing the same.[0003] 2. Description of the Related Art[0004] An oxide substrate or an oxide base such as MgO, alumina or YSZ, or a metal substrate or a metal base such as Ag, Au, Pt or Ni is formed with an oxide superconductor in thick film form to function, so as to devise a variety of applied products.[0005] As a method of forming this oxide superconductor into film form, a technique is tried in which an oxide superconductor powder, to which an appropriate organic binder is added, is made into paste form, thereafter applied to the substrate or the base using the screen printing method, the doctor blade method, the spray method, or the like, and burned to thereby form a polycrystalline oxide superconductor thick film....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G29/00C01G1/00H01B12/06H01B13/00H01L39/24

CPCH01L39/2429Y10S505/782H10N60/0352

Inventor KOJIMA, MASAHIROKAWAHARA, MASAKAZUICHIKAWA, MICHIHARUKADO, HIROYUKISHIBUYA, MASATOYO

Owner DOWA ELECTRONICS MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com