Multi-piece solid golf ball

Inactive Publication Date: 2004-10-07

DUNLOP SPORTS CO LTD

View PDF8 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

0009] A main object of the present invention is to provide a multi-piece solid golf b

Problems solved by technology

In the golf ball, since the cover is formed from ionomer resin as a base resin, the spin performance of the resulting golf ball is not sufficiently obtained, and the controllability is poor.

In addition, the scuff resistance is not sufficiently obtained.

In the golf ball, since the cover is formed from ionomer resin as a base resin, the hardness of the cover is high, and the shot feel and controllability are poor.

However, since the cover has low hardness and large thickness, the rebound characteristics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

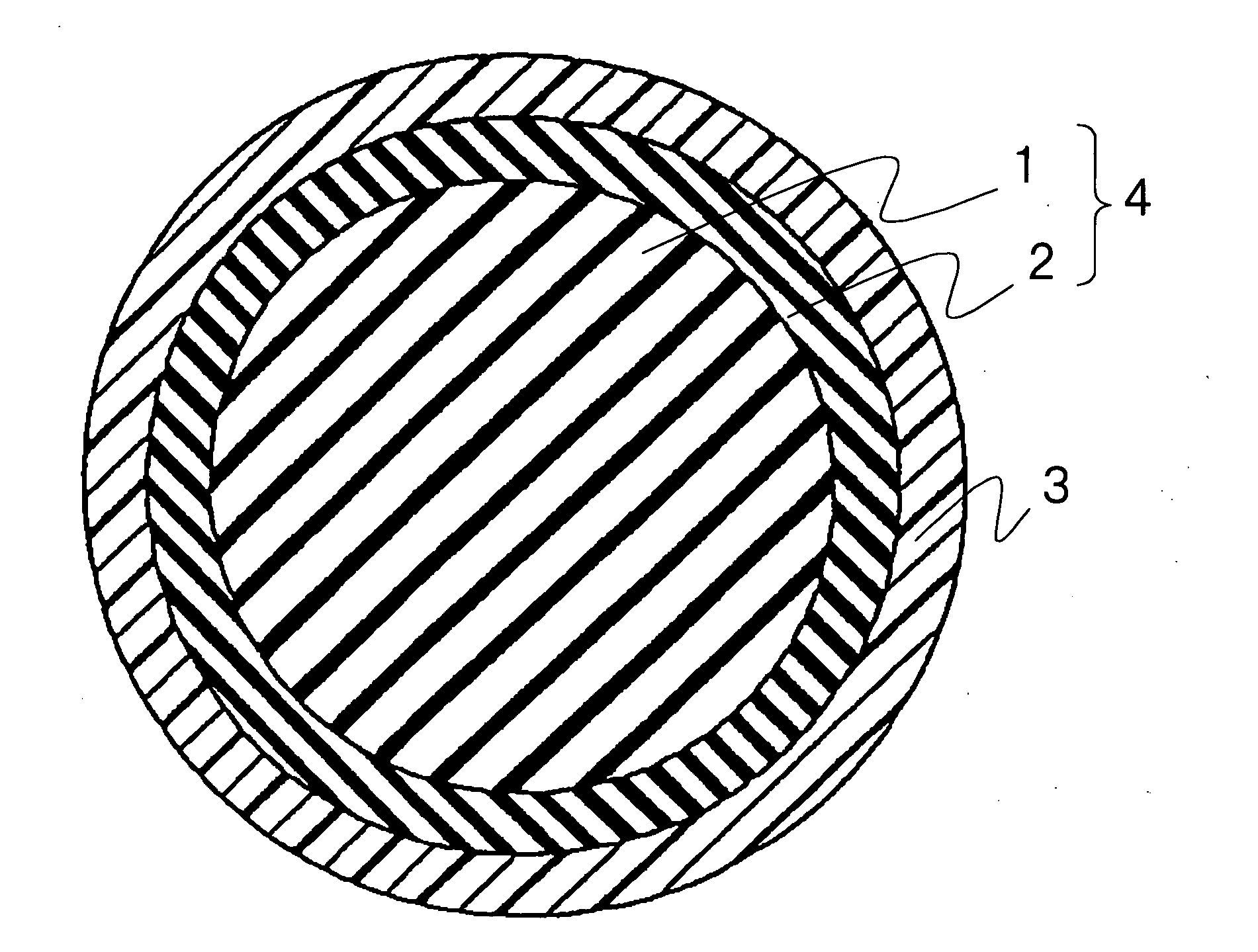

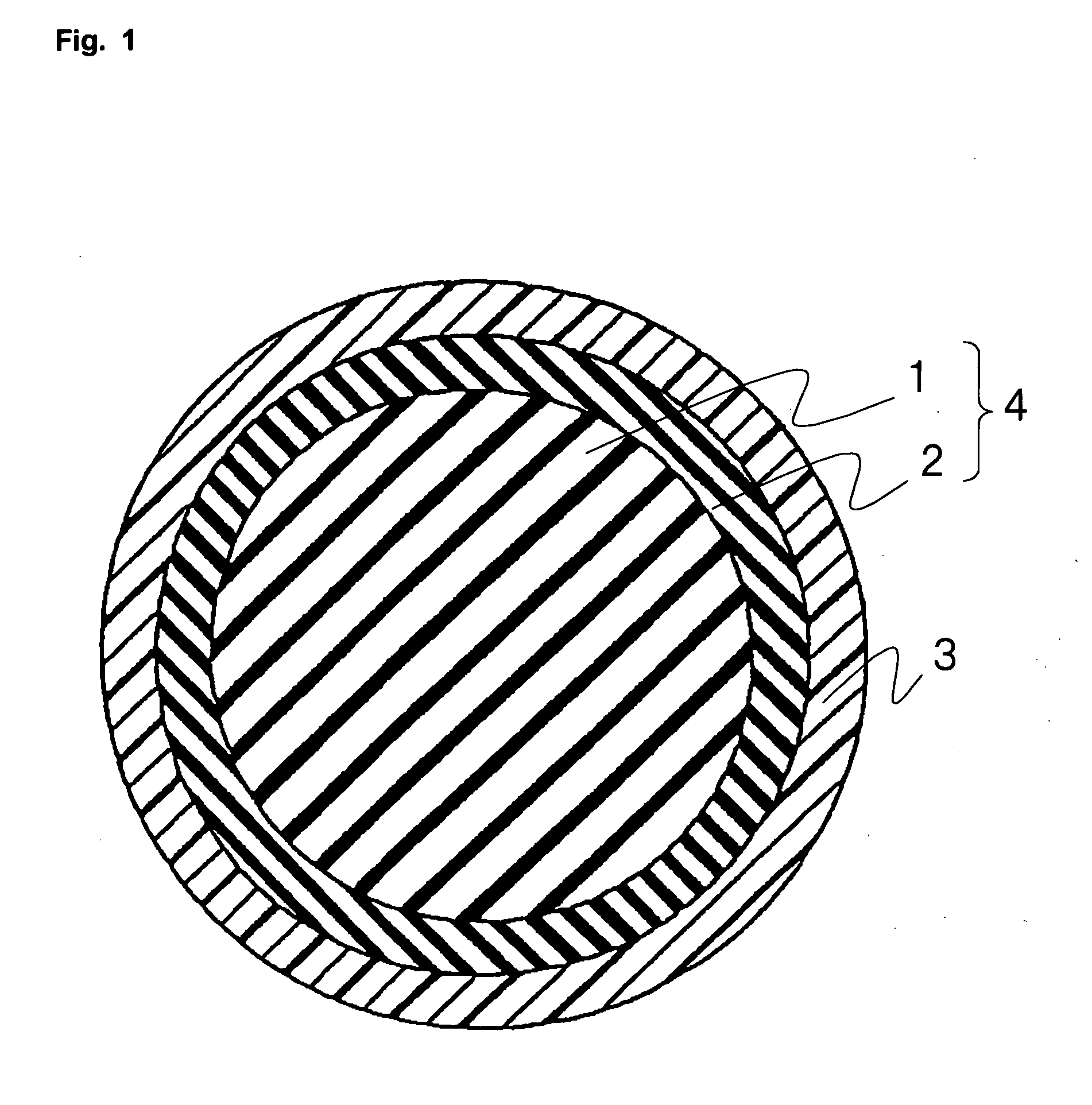

The present invention provides a multi-piece solid golf ball having good shot feel, excellent flight performance and excellent controllability. The present invention relates to a multi-piece solid golf ball comprising a core composed of a center and at least one intermediate layer formed on the center, and a cover covering the core, wherein assuming that a central point hardness of the center, a surface hardness of the center, a hardness of the intermediate layer and a hardness of the cover in Shore D hardness are represented by HM, HS, HI and HC, respectively, the HM, HS, HI and HC satisfy a correlation represented by the following formula: HM<HS<HI<HC and the cover is formed from polyurethane material as a main component, and has a hardness in Shore D hardness of 45 to 60.

Description

[0001] The present invention relates to a multi-piece solid golf ball. More particularly, it relates to a multi-piece solid golf ball having good shot feel, excellent flight performance and excellent controllability.[0002] In golf balls commercially selling, there are solid golf balls such as two-piece golf ball, three-piece golf ball and the like, and thread wound golf balls. Recently, the two-piece golf ball and three-piece golf ball, of which flight distance can be improved while maintaining soft and good shot feel at the time of hitting as good as the conventional thread wound golf ball, generally occupy the greater part of the golf ball market. Multi-piece solid golf balls represented by three-piece golf ball have good shot feel while maintaining excellent flight performance, because they can vary hardness distribution and design of golf balls, when compared with the two-piece golf ball.[0003] The three-piece solid golf balls are obtained by inserting an intermediate layer betw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A63B37/00A63B37/04

CPCA63B37/0003A63B37/0031A63B37/0043A63B37/0062A63B37/0075A63B37/0076A63B37/04A63B37/00622A63B37/00621

Inventor SASAKI, TAKASHI

Owner DUNLOP SPORTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com