Structured abrasive article

a structured abrasive and article technology, applied in the direction of abrasive equipment, metal-working equipment, manufacturing tools, etc., can solve the problems of inability to effectively withstand high cutting ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

This invention pertains to an abrasive array, an abrasive article, a method of making an abrasive article and a method of using an abrasive article.

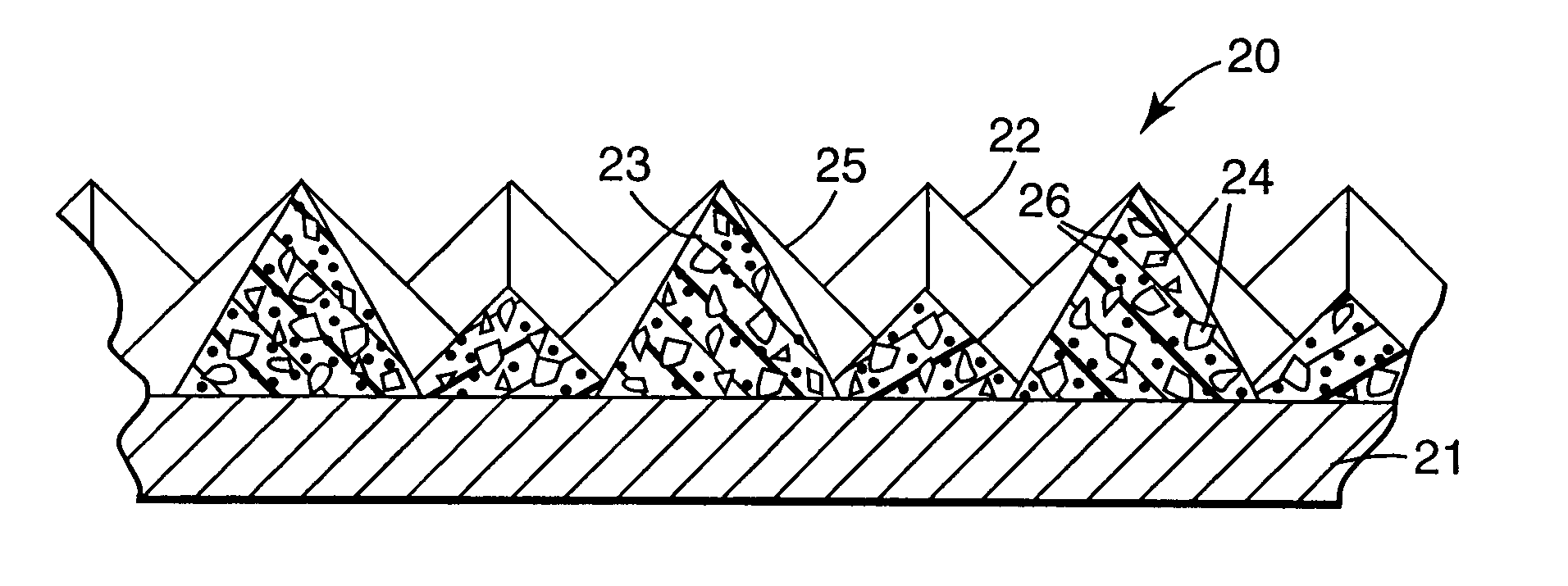

Referring to FIG. 1, the abrasive article 20 comprises abrasive composites 22 separated by boundary 25. The abrasive composites are bonded to a surface of a backing 21. The boundary or boundaries associated with the composite shape result in one abrasive composite being separated to some degree from another adjacent abrasive composite. To form an individual abrasive composite, a portion of the boundaries forming the shape of the abrasive composite must be separated from one another. Note that in FIG. 2, the base or a portion of the abrasive composite closest to the backing can abut with its neighboring abrasive composite. (Note that “neighboring” does not necessarily mean “adjacent”.) Abrasive composites 22 comprise a plurality of abrasive particles 24 that are dispersed in a binder 23 and a grinding aid 26. It is also within the scop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com