Supporting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

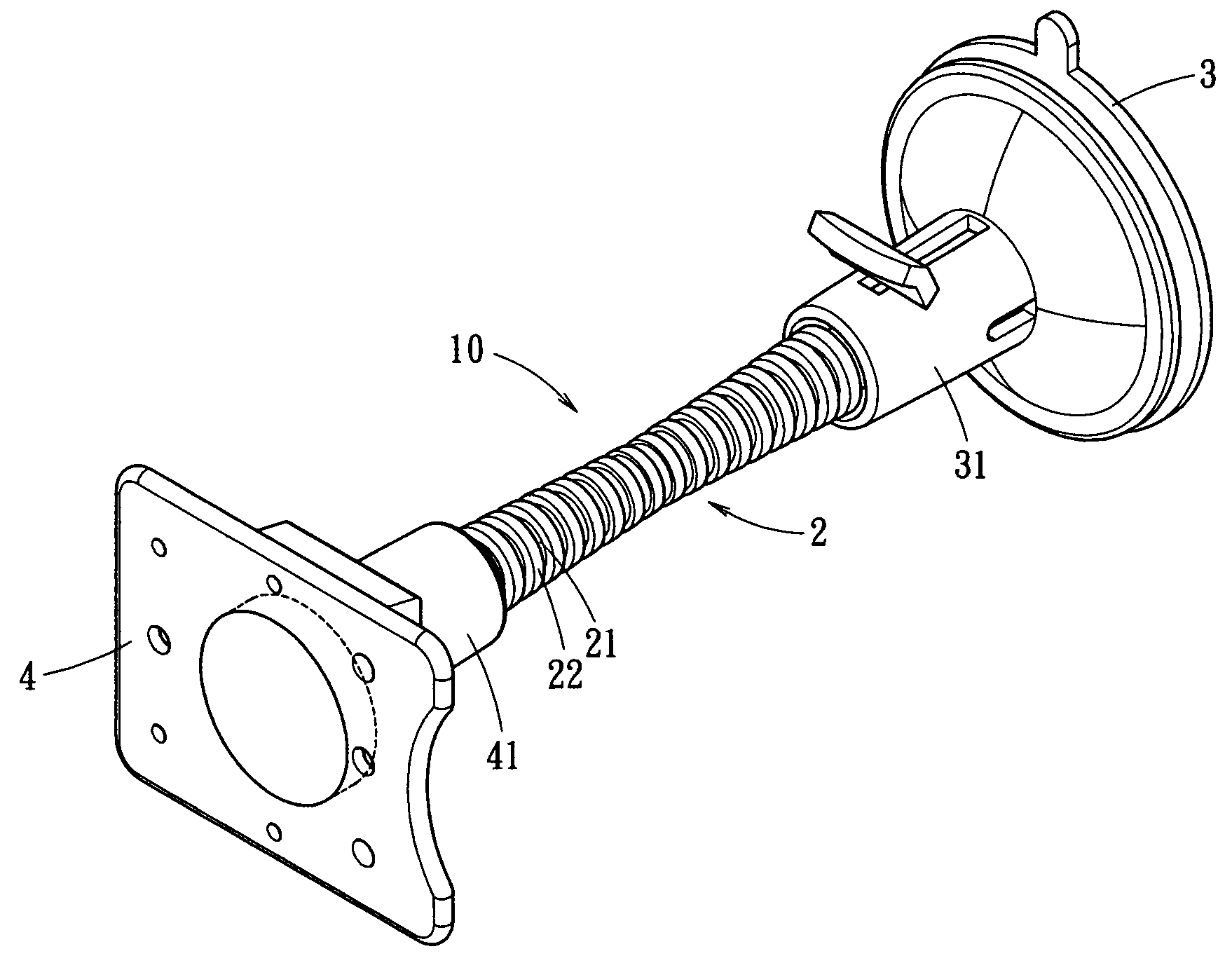

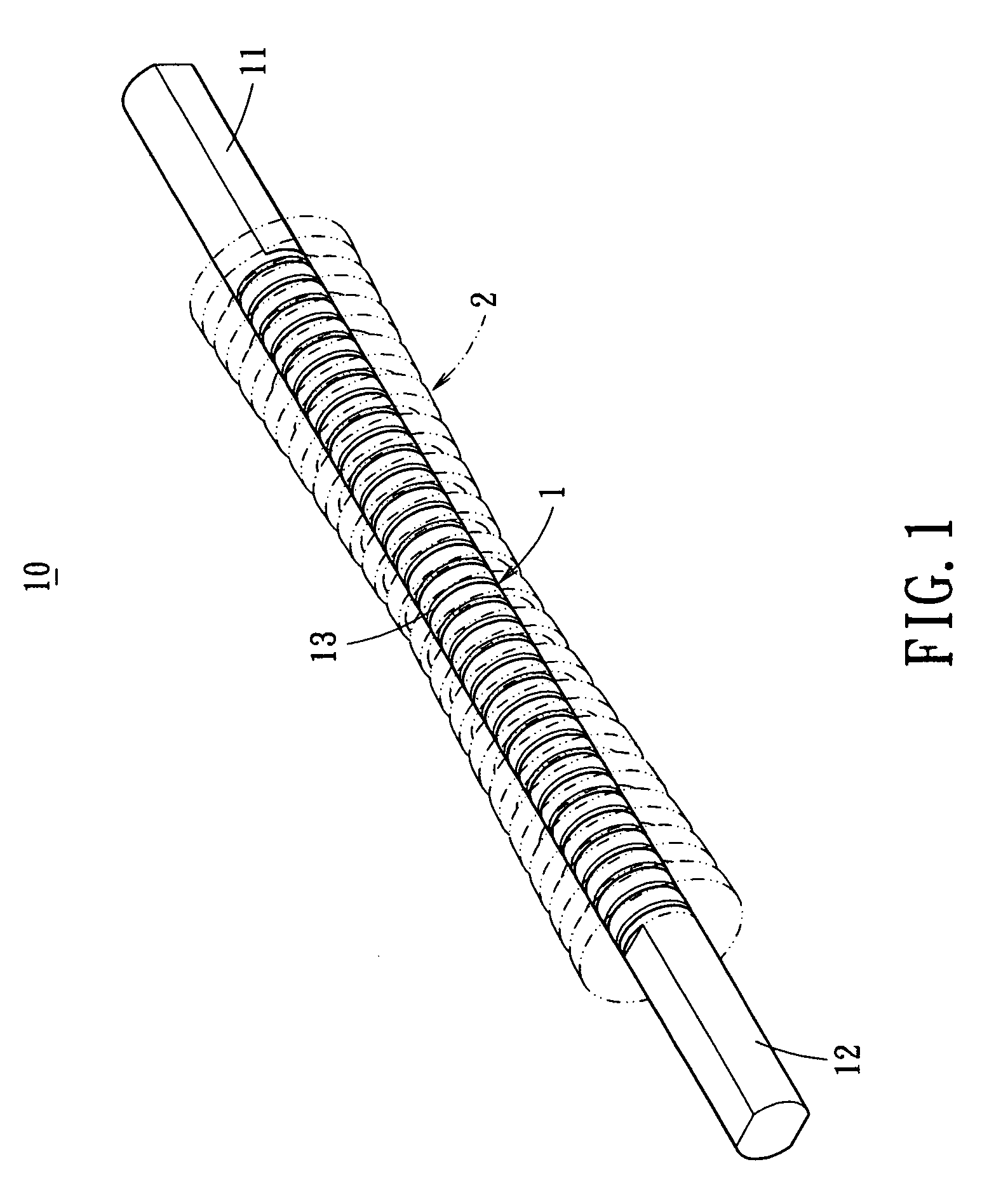

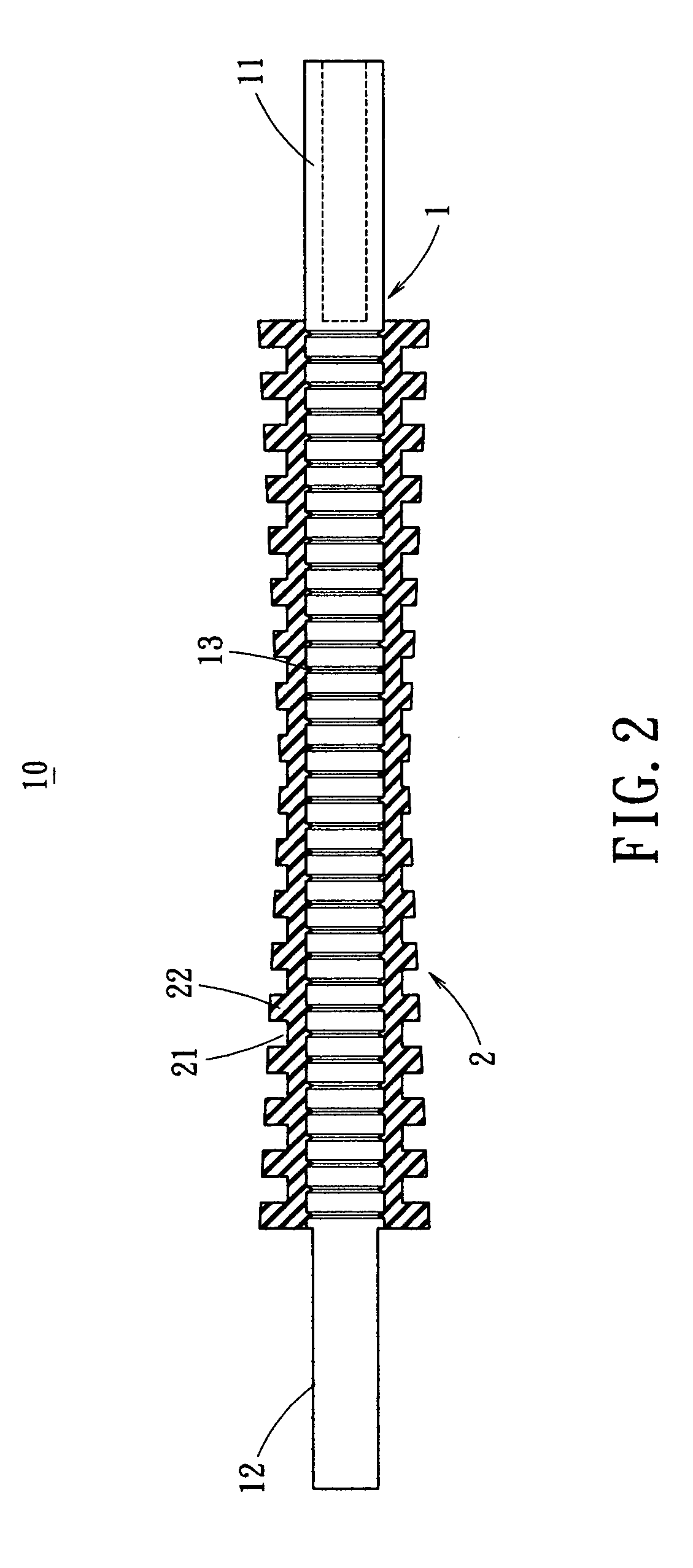

[0015] As shown in FIGS. 1 and 2, the supporting structure provided by the present invention comprises an elongate body member 1. Preferably, the body member is made of flexible material such as aluminum material to be bendable or foldable with any degree as desired.

[0016] An exterior covering member 2 is formed to wrap around the elongate body member 2. In this embodiment, the exterior covering member 2 is formed by direct mold injection onto the side surface of the body member 2 with two connecting ends 11 and 12 exposed thereby. In this embodiment, the exterior covering member 2 is fabricated from soft plastic material with bellow configuration. That is, the exterior covering member 2 includes alternative recessed slots 21 and protruding ribs 22 along an elongate direction thereof. Further, the exterior covering member 2 has a gradually reduced diameter from two ends to the center thereof.

[0017] The elongate body member 1 made of flexible aluminum material has a roughened surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com