Cleaning system for shirt collar and sleeves

a collar and sleeves technology, applied in the field of shirt collar and sleeves cleaning system, can solve the problems of fatigue in arms and hands, dirty collar and sleeves, stubborn rings around them, etc., and achieve the effect of optimal stain removal and cleaning stubborn stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

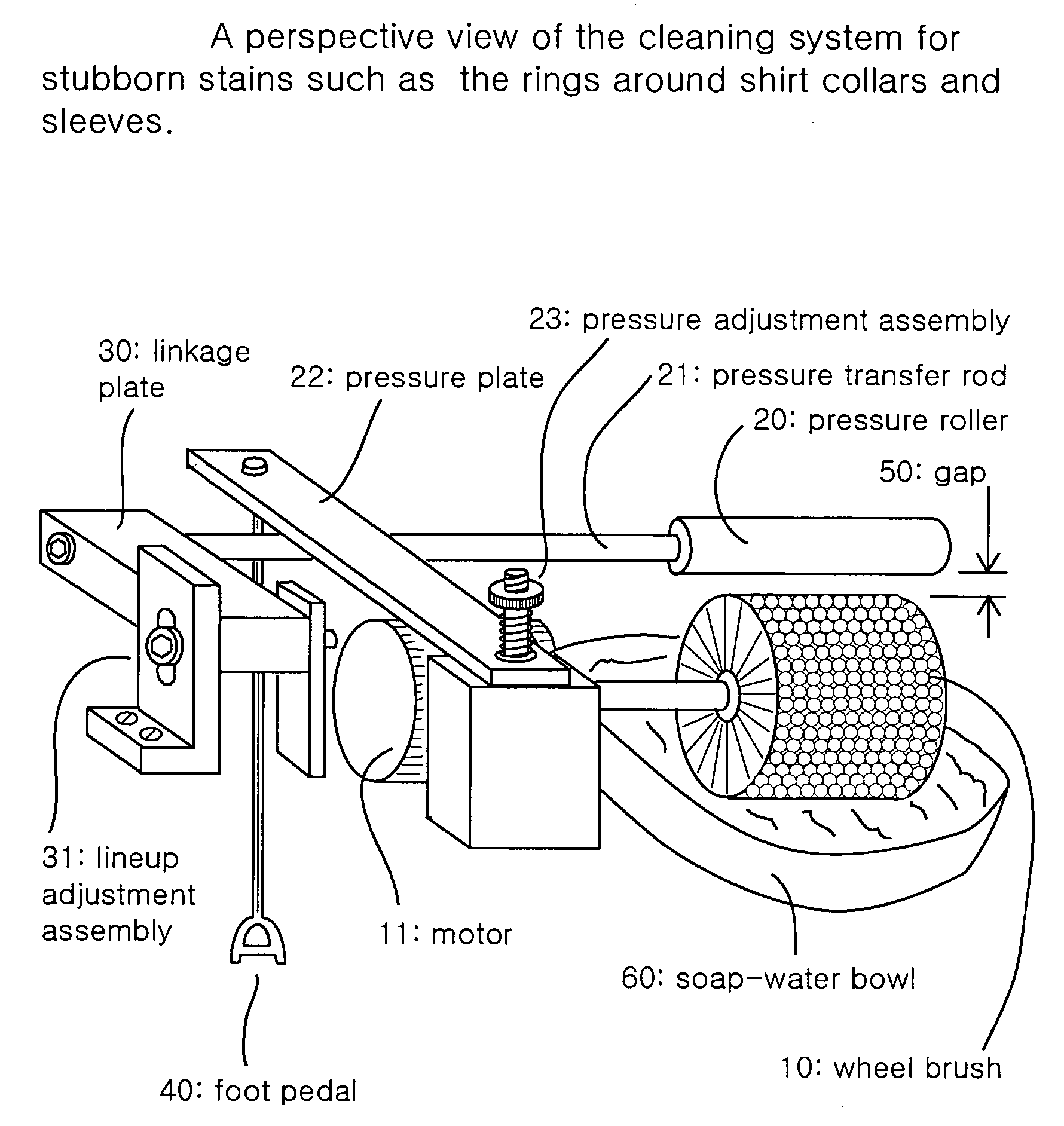

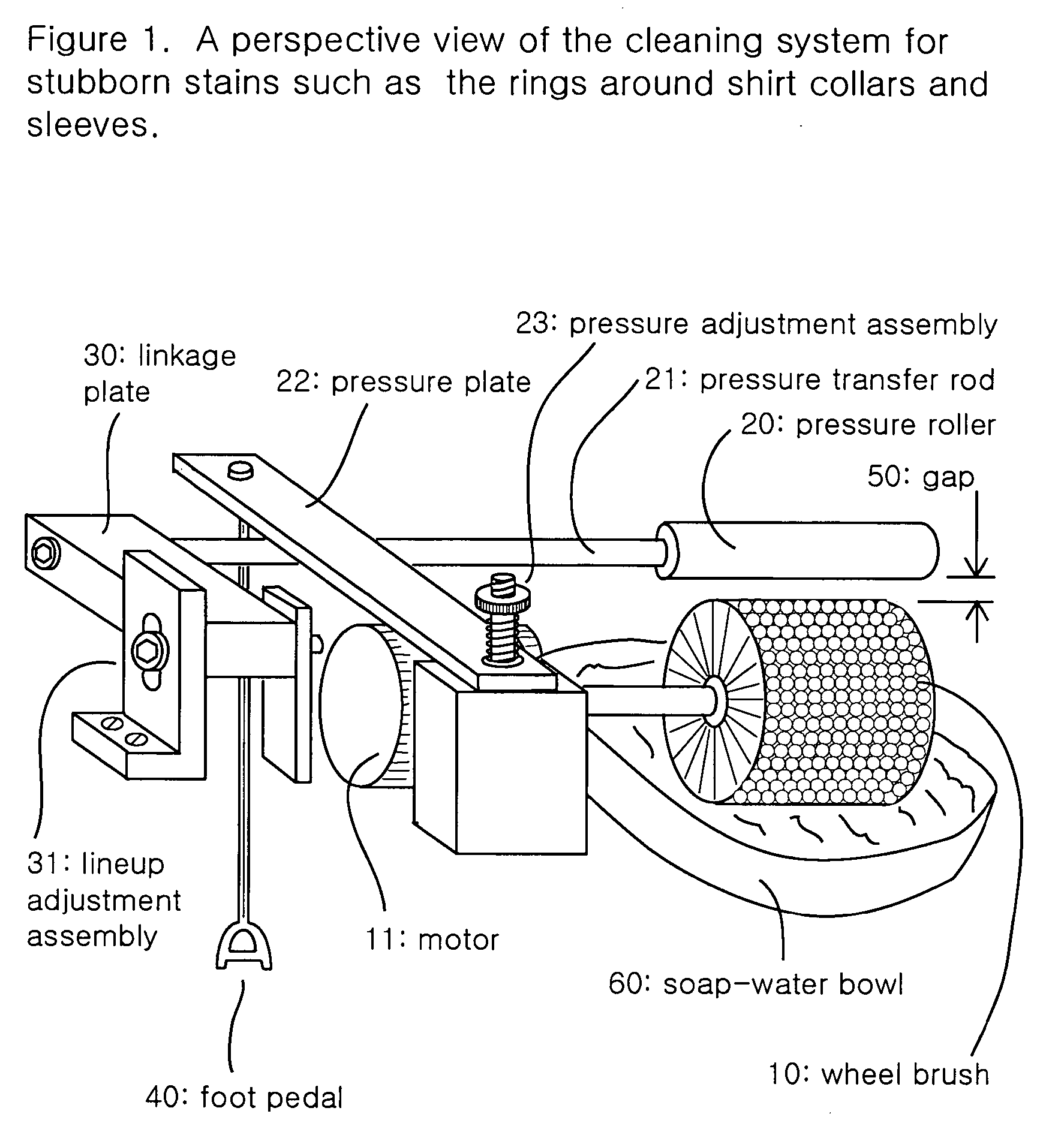

[0006] With the reference to the accompanying drawing, the present invention will now be described. As shown in FIGS. 1, the present invention is provided as a cleaning system for stubborn stains such as the rings around shirt collar and sleeves comprising a wheel brush 10 driven by a motor 11, a soup-water bowl 60, a free-spinning pressure roller 20, a pressure transfer rod 21, a pressure plate 22, a pressure adjustment assembly 23, a linkage plate 30, a lineup adjustment assembly 31, and a foot pedal 40. All of the parts are set up on a table except the foot pedal.

[0007] The main idea of this invention is to place the heavily stained color and sleeve edges of a dress shirt onto a rotating wheel brush with an optimal pressure to get the stubborn stains out, and then wash the shirt in a washing machine. When idle, there is a gap 50 between the wheel brush 10 and the pressure roller 20 so the operator can place the shirt collar or a sleeve edge between them. The shirt collar is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com