Method and apparatus for making flexible articles having elastic-like behavior with visually distinct regions

a technology of elastic-like behavior and flexible articles, applied in the field of method and apparatus for the production of flexible articles, can solve the problems of difficult separation for subsequent processing, excessive blocking characteristics of thermoplastic elastomeric films, and even more acute problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In this detailed description of the present invention, any patent or non-patent literature referenced herein and the disclosure contained therein is intended to be and is hereby incorporated by reference.

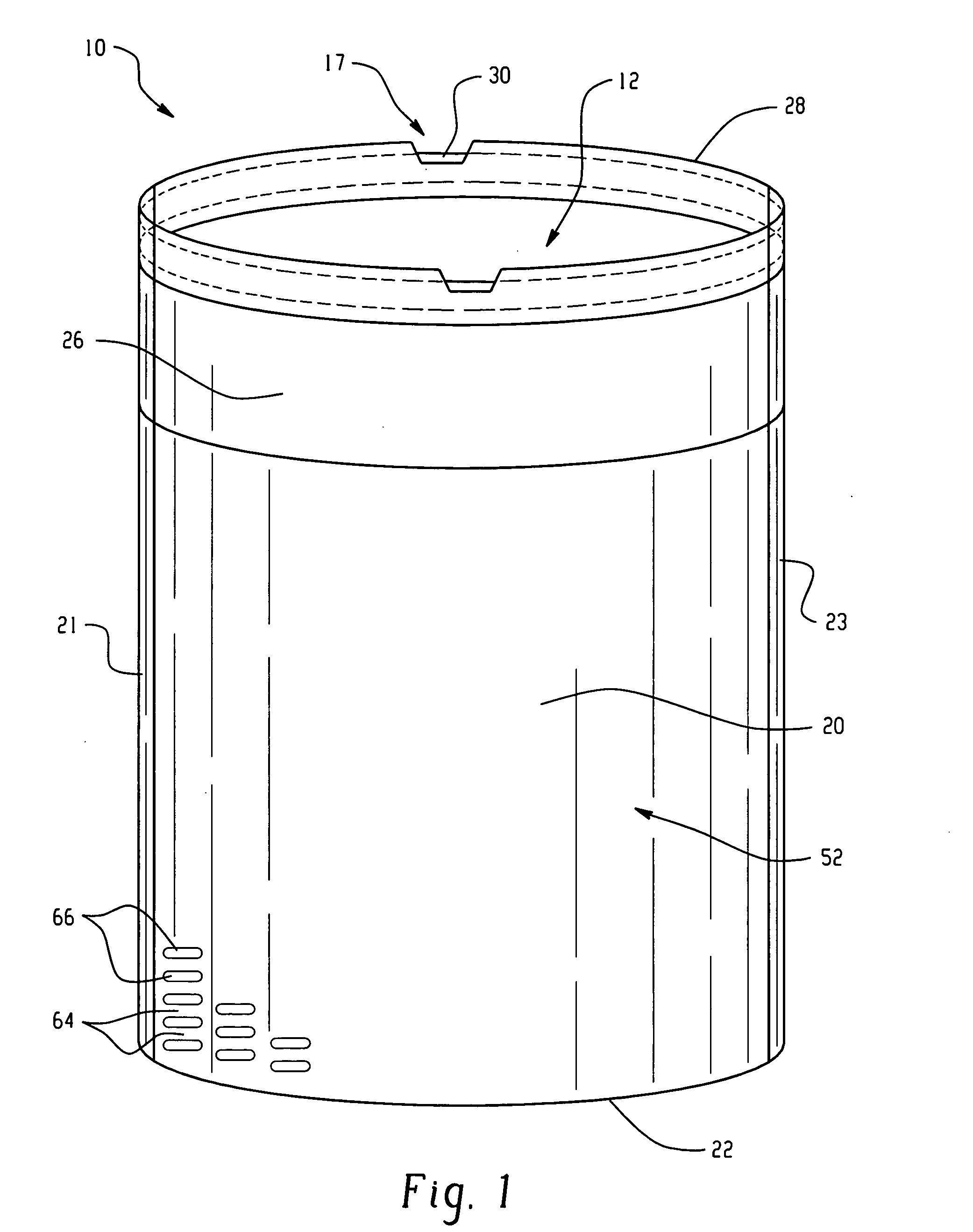

[0028] Referring now to FIG. 1 in which is illustrated a preferred embodiment of a flexible bag 10 made according to the present invention. Flexible bag 10 includes bag body 20, an opening along top edge 28, a sealed first seam 21, a sealed second seam 23, and a closed bottom formed at bottom fold 22. Preferably, flexible bag 10 includes first regions 64 and second regions 66 forming a strainable network across bag body 20. In one embodiment of flexible bag 10, first regions 64 are in a substantially crisscrossing pattern across bag body 20. In this embodiment, flexible bag 10 is tubular in shape and has an interior 12. Flexible bag 10 is illustrated with optional closure means 30 located at or adjacent to top edge 28. Optional closure means 30 can be used to close flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com