Pump controller for precision pumping apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention is particularly applicable to a pumping apparatus which accurately dispenses precise amounts of low viscosity fluids and it is in this context that the invention will be described. It will be appreciated, however, that the apparatus and method in accordance with the invention has greater utility, such as to accurately dispensing precise amounts of other fluids which may not be low viscosity fluids.

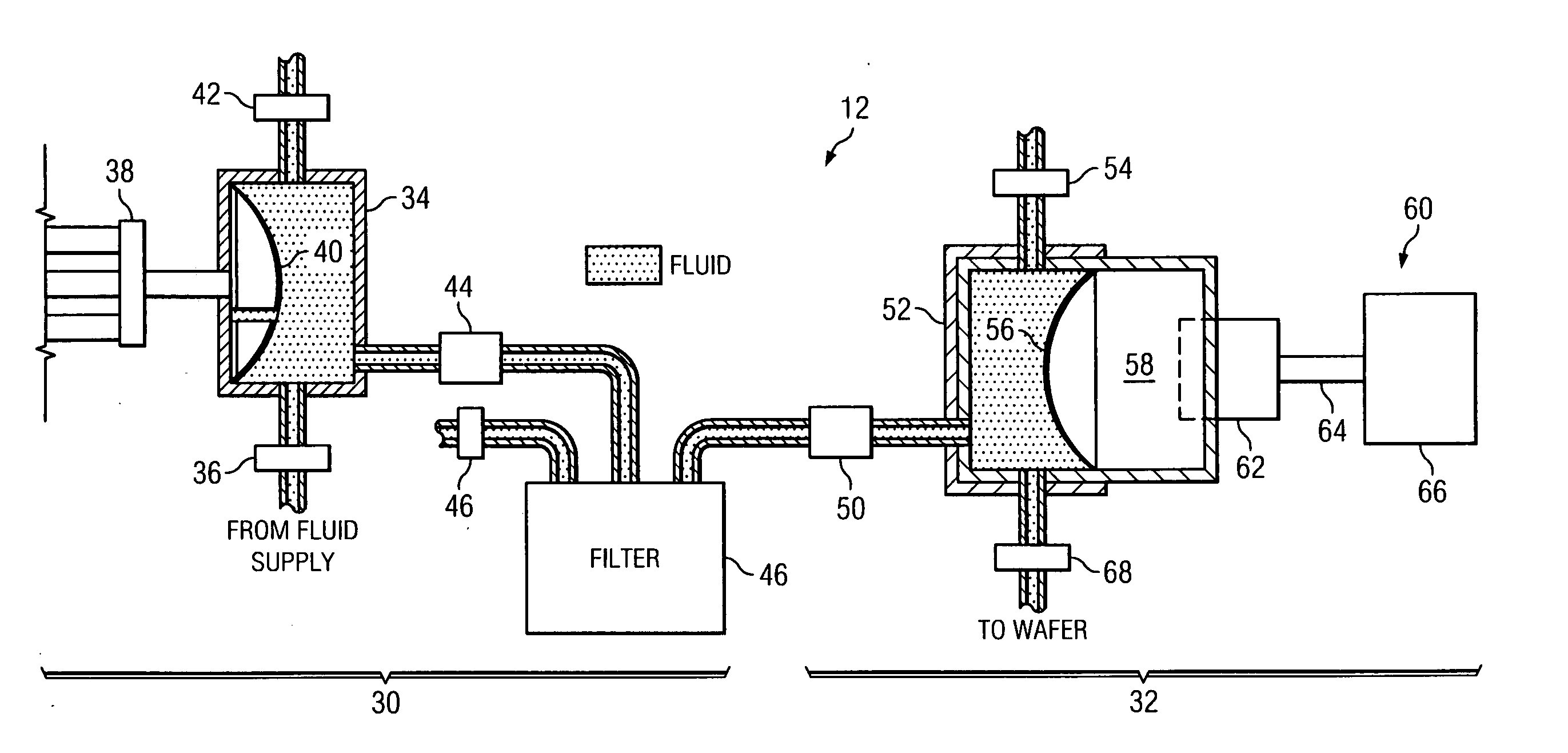

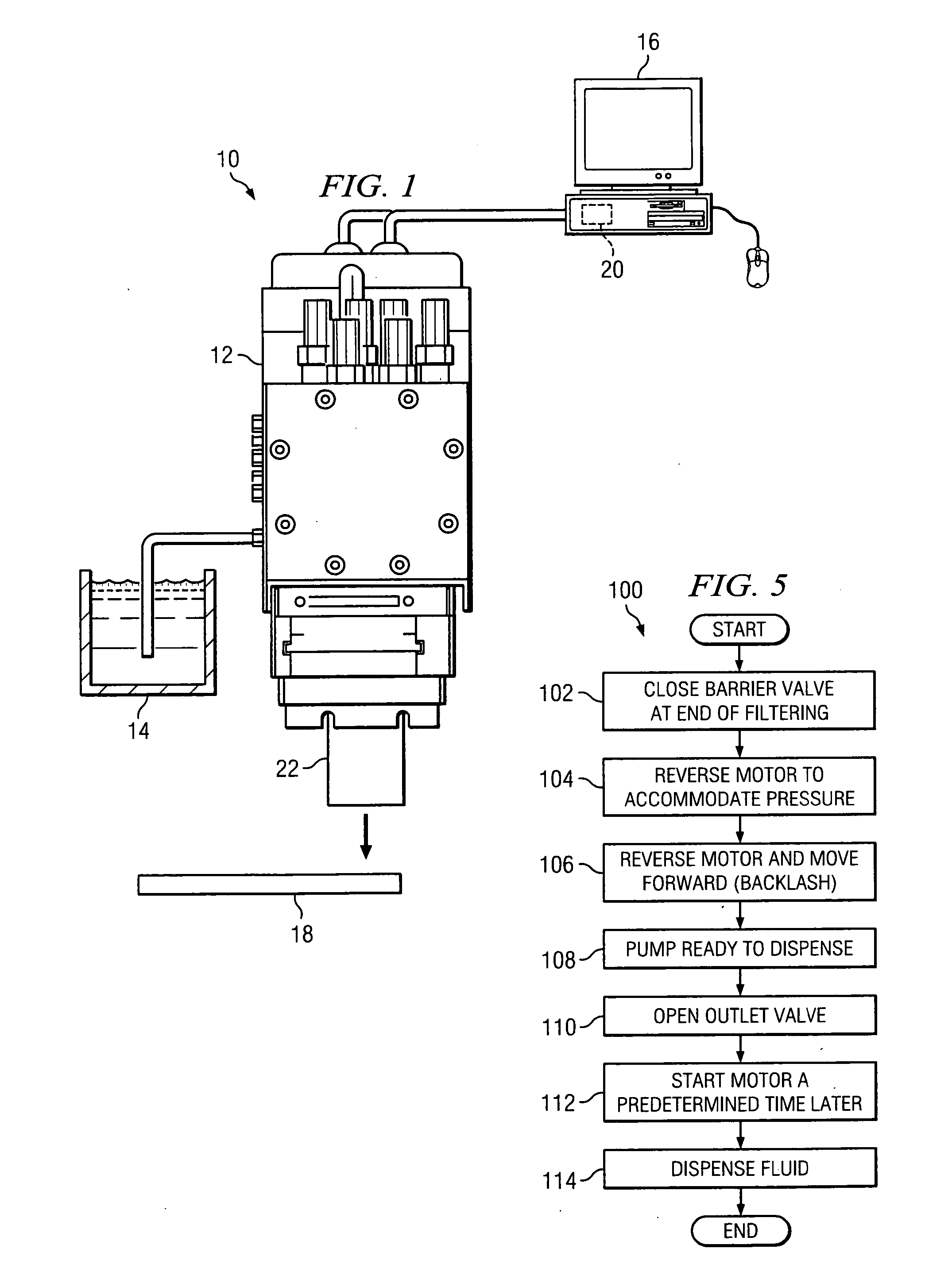

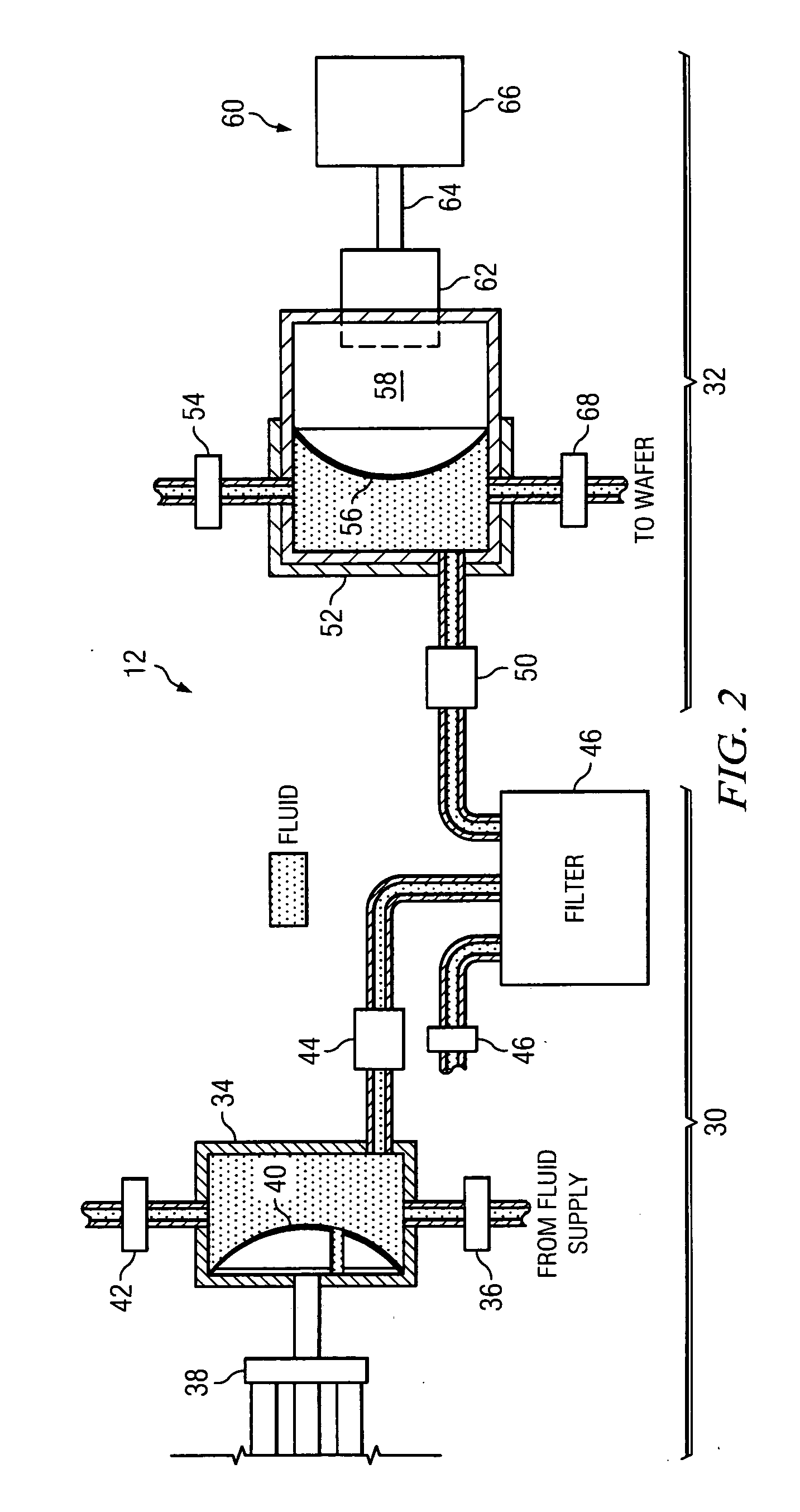

[0013]FIG. 1 is a block diagram illustrating a pumping apparatus 10 including a pump controller in accordance with the invention. The pumping apparatus 10 may include a two-stage pump 12, a fluid reservoir 14 and a computer 16 which operate together to dispense a precise amount of fluid onto a wafer 18. For purposes of illustration, a low viscosity fluid, which may have a viscosity of less than 5 centipoire (cPs), may be dispensed at a low flow rate of about 0.5 milliliters per second, but the invention is not limited to dispensing low viscosity fluids or low flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com