Shaft for use in golf clubs and other shaft-based instruments and method of making the same

a technology for golf clubs and shafts, applied in the field of shaft-based instruments, can solve the problems of difficult to overcome, the location of the flex point of the shaft, and the design problems of the shaft-based instrument manufacturer, and achieve the effects of facilitating the precise location of the flex point, and reducing the risk of shaft breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a detailed description of the best presently known modes of carrying out the inventions. This description is not to be taken in a limiting sense, but is made merely for the purpose of illustrating the general principles of the inventions. The scope of the inventions is defined by the appended claims. Additionally, although the present inventions are described herein in the golf club shaft context because the inventions are particularly well suited to golf club shafts, the inventions are not so limited. The inventor herein has determined that present inventions have application in other shaft-based devices such as, for example, ski poles and hockey sticks.

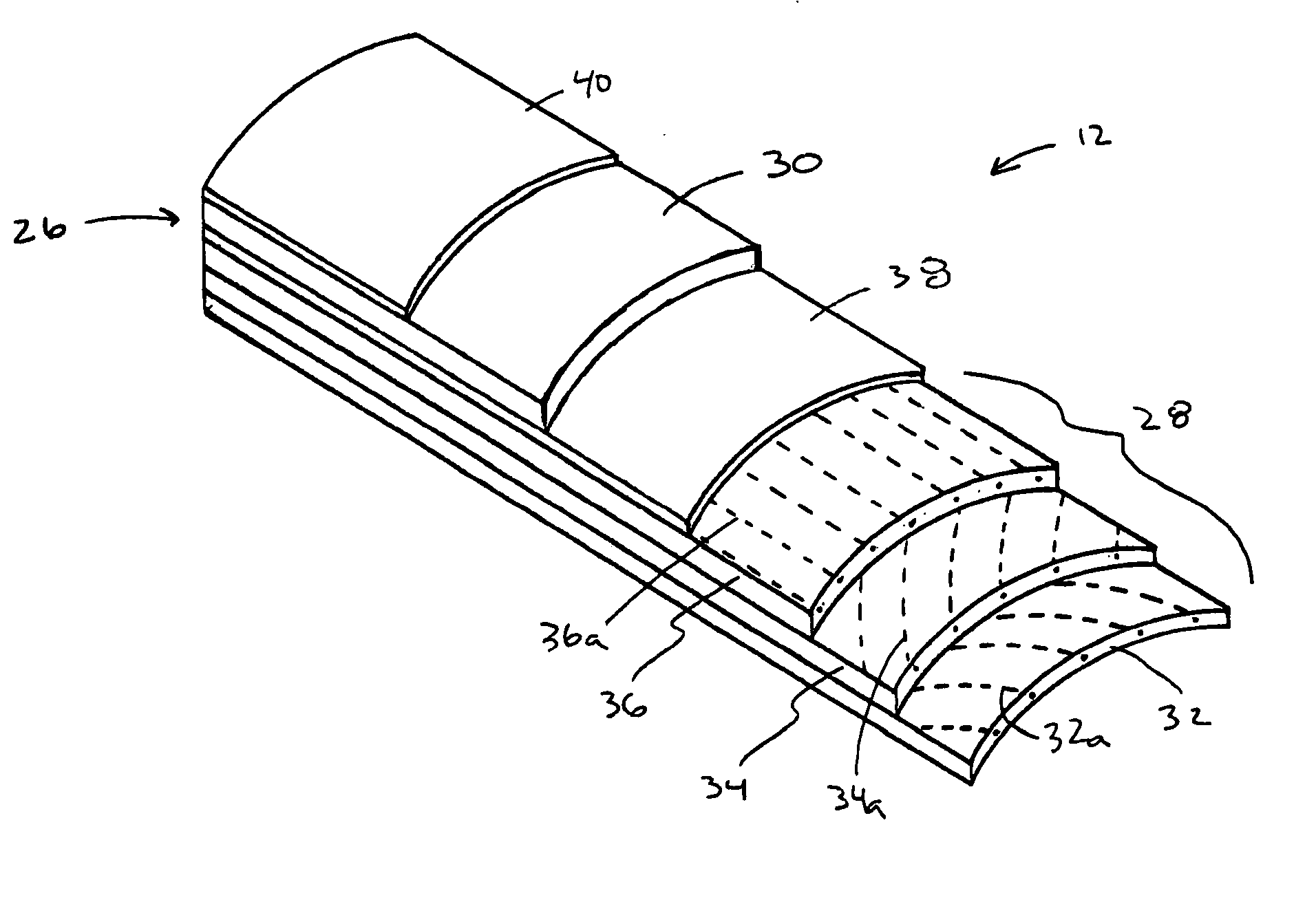

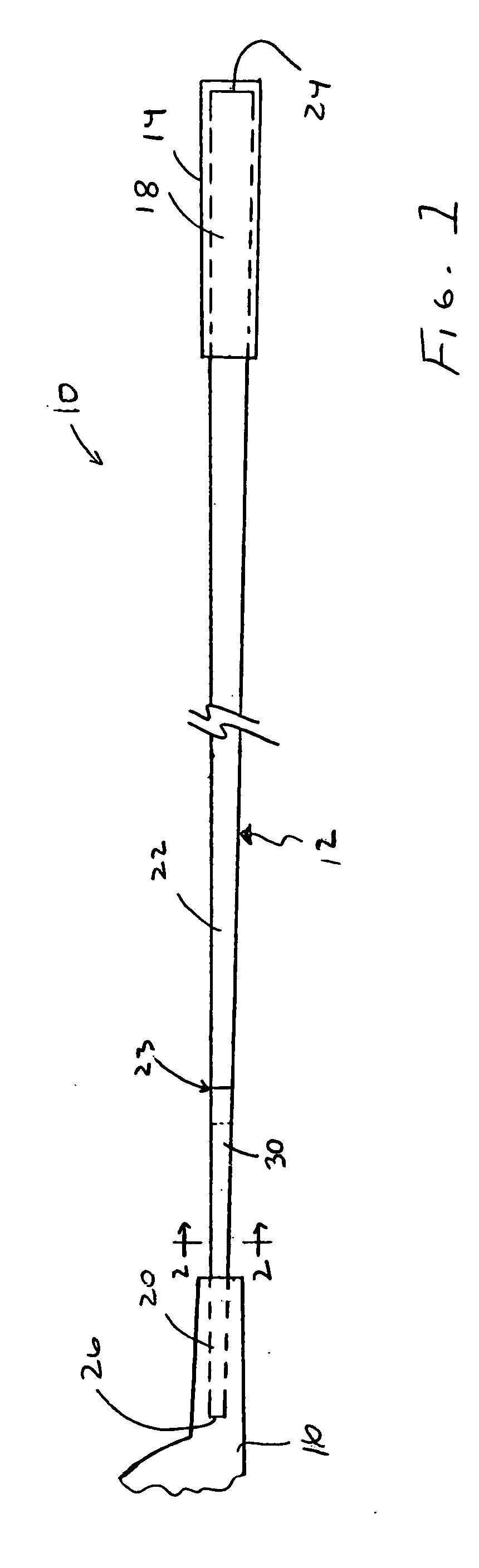

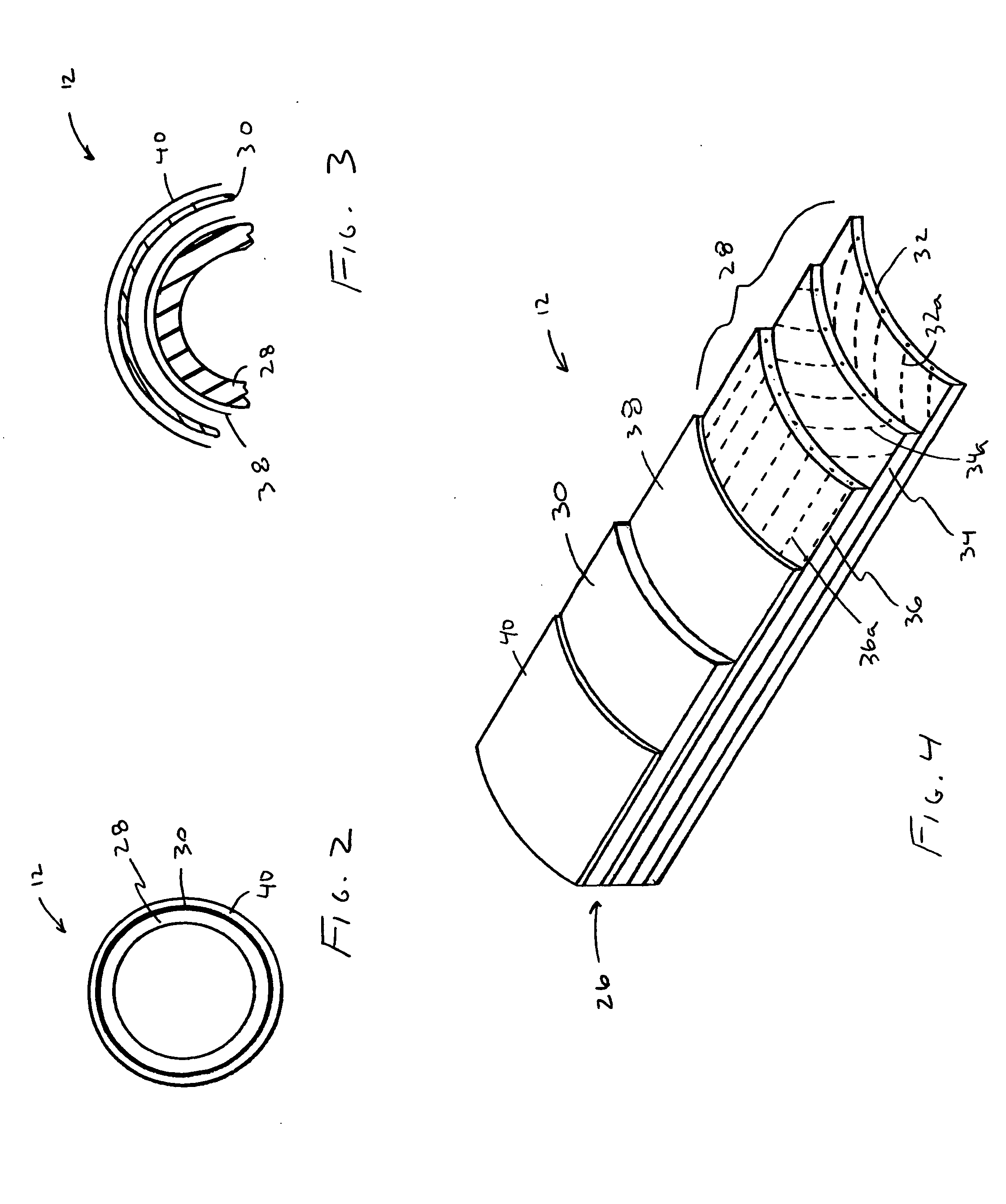

[0023] As illustrated for example in FIG. 1, a golf club shaft 10 in accordance with a preferred embodiment of a present invention includes a hollow shaft 12, a grip 14, and a club head 16. The exemplary shaft 12 is divided into three sections—the grip section 18 which is covered by the grip 14, the tip sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com