Method for manufacturing artificial nail

a manufacturing method and nail technology, applied in the field of artificial nail manufacturing, can solve the problems of reducing the yield of artificial nails which can be cumbersome operation of manicuring nails, and reducing the number of artificial nails produced at one time, so as to achieve rapid mass production without increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

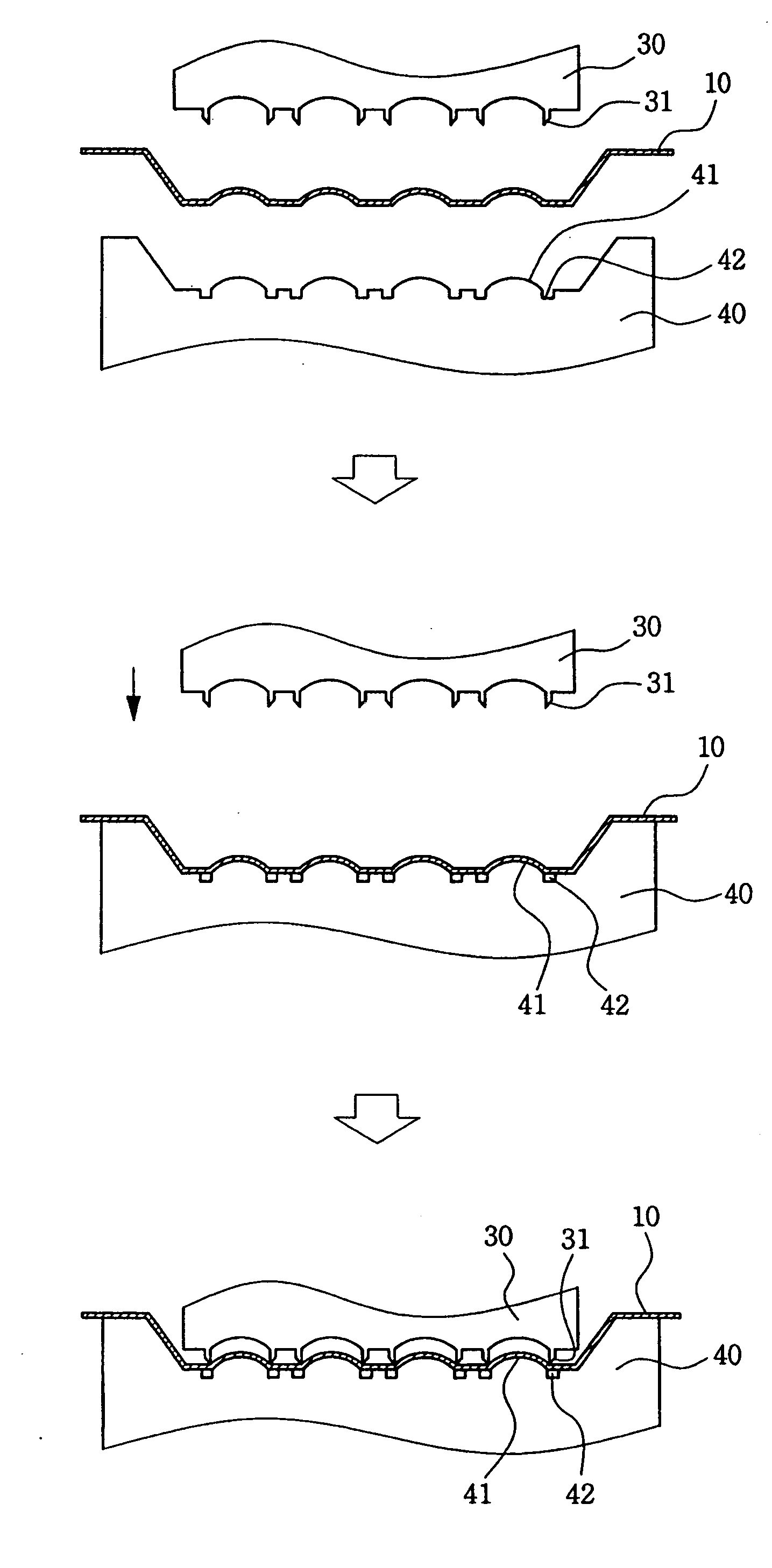

[0024] Hereinafter, a preferred embodiment of a method for manufacturing an artificial nail according to the present invention will be described with reference to the accompanying drawings.

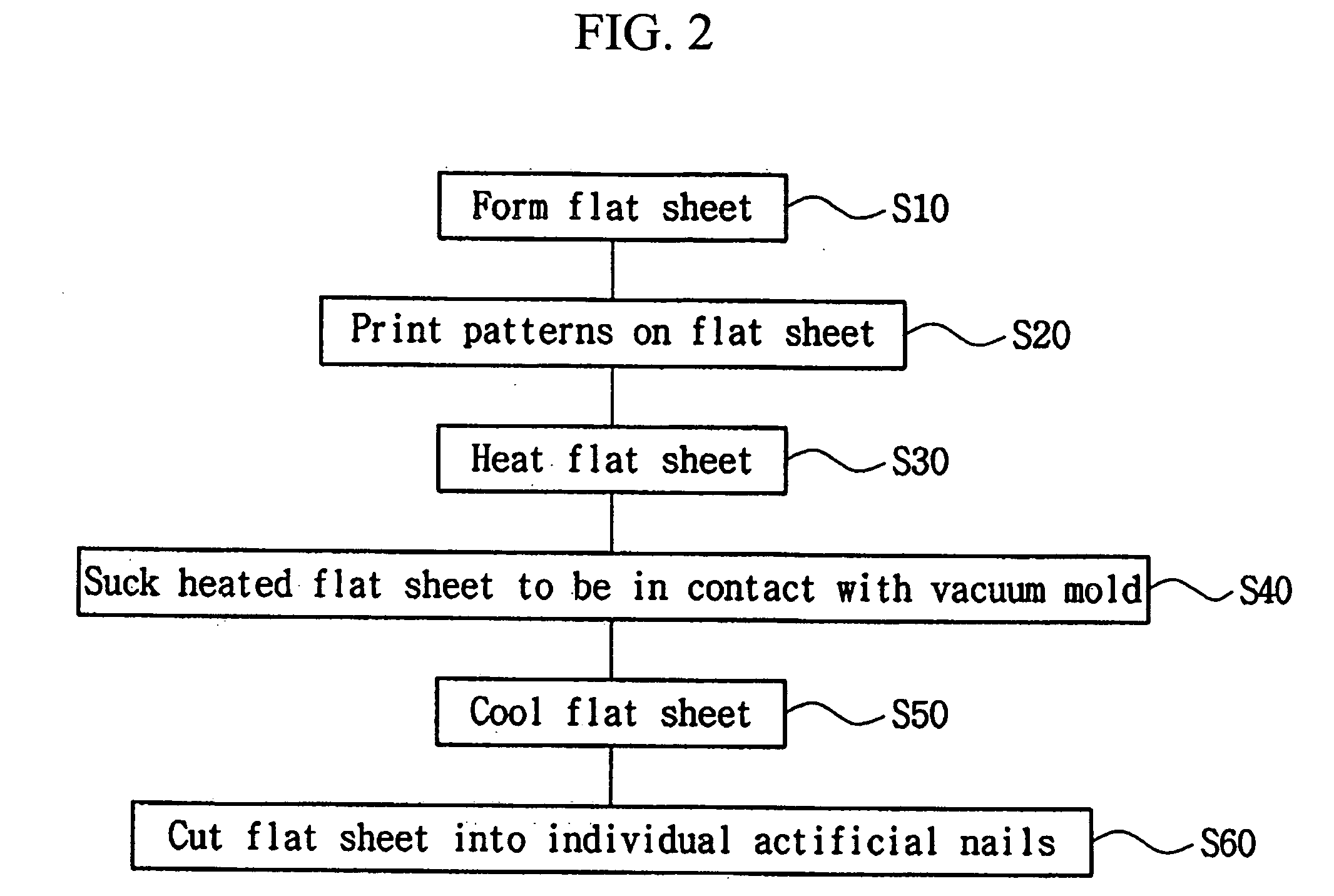

[0025]FIG. 2 is a flowchart illustrating the method for manufacturing an artificial nail according to the present invention. Referring to FIG. 2, an artificial nail is manufactured by sequentially performing the steps of forming a flat sheet (S10), performing printing on the flat sheet (S20), heating the flat sheet (S30), sucking the heated planar-sheet (S40), cooling the sheet molded by the suction (S50), and cutting the molded sheet (S60).

[0026] The flat sheet in the present invention can be molded out of the same ABS resin as has been used in the prior art. According to the present invention, the flat sheet can also be extruded using polyethylene terephthalate (PET) resin that has not been used as a material of the artificial nail in a conventional method since it is difficult to separate a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| colors | aaaaa | aaaaa |

| period of time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com