Self-activating downhole tool

a self-activating, downhole technology, applied in the direction of fluid removal, borehole/well accessories, survey, etc., can solve the problems of increased safety concerns, time-consuming and costly operations, and mechanical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

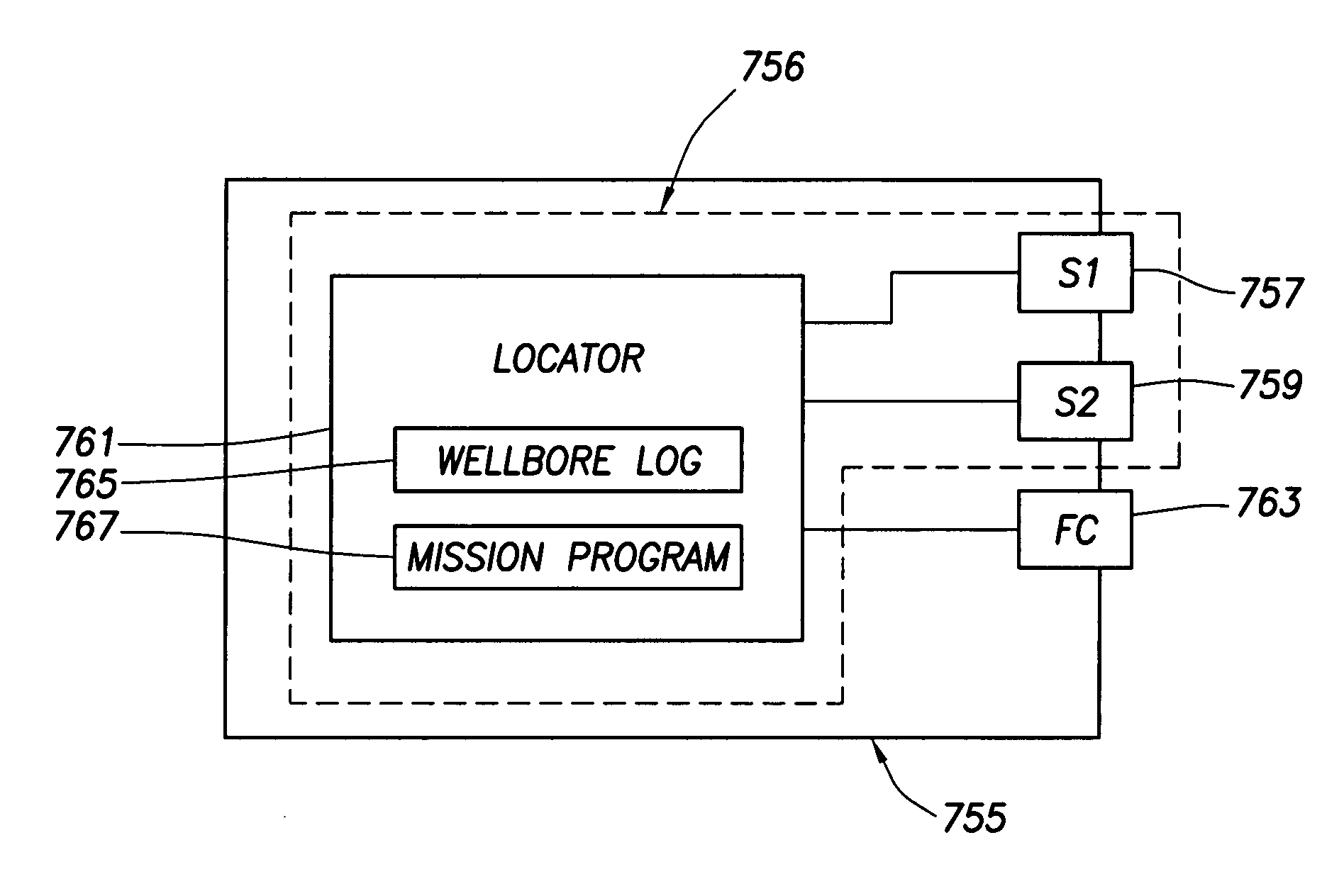

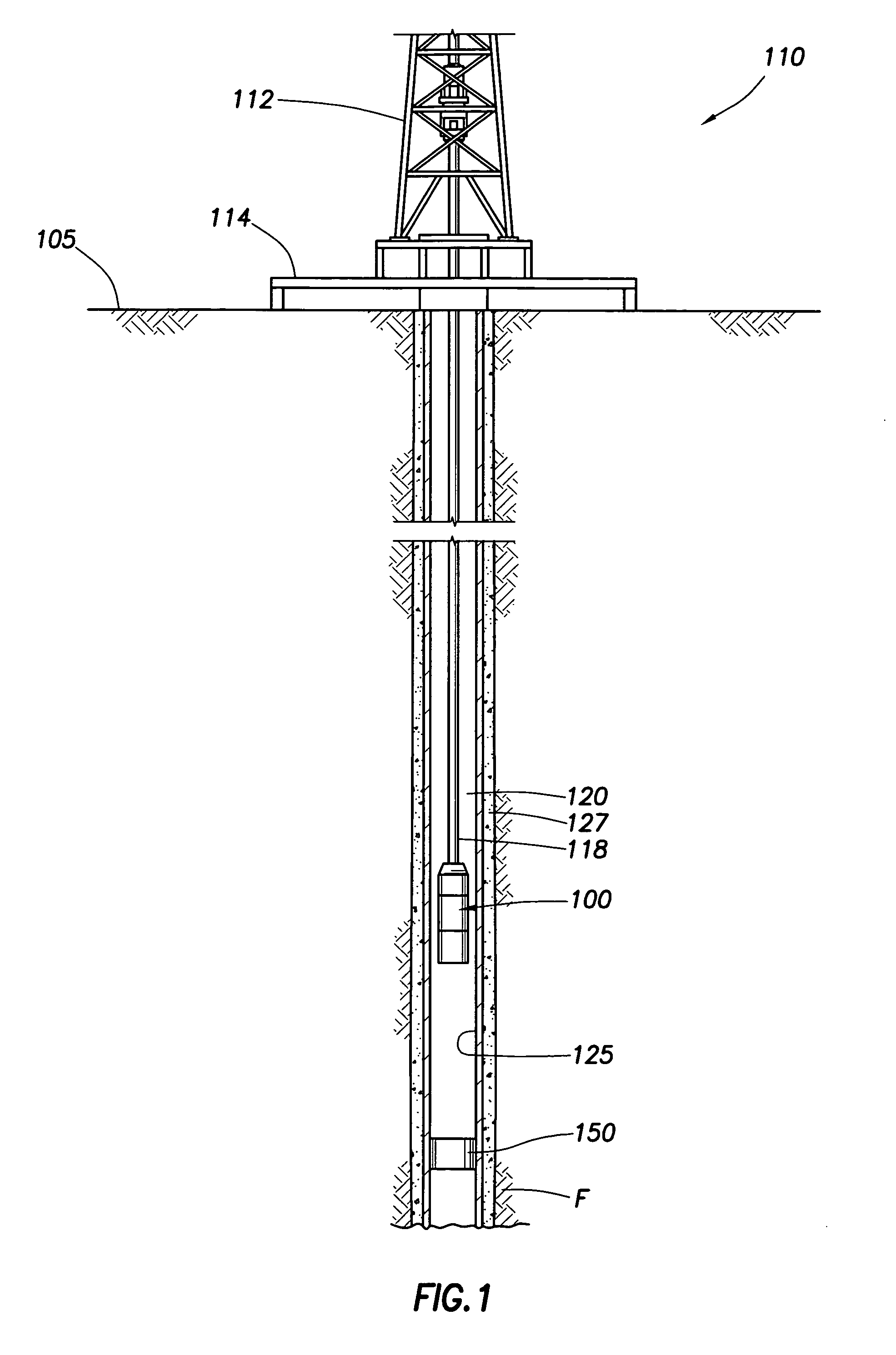

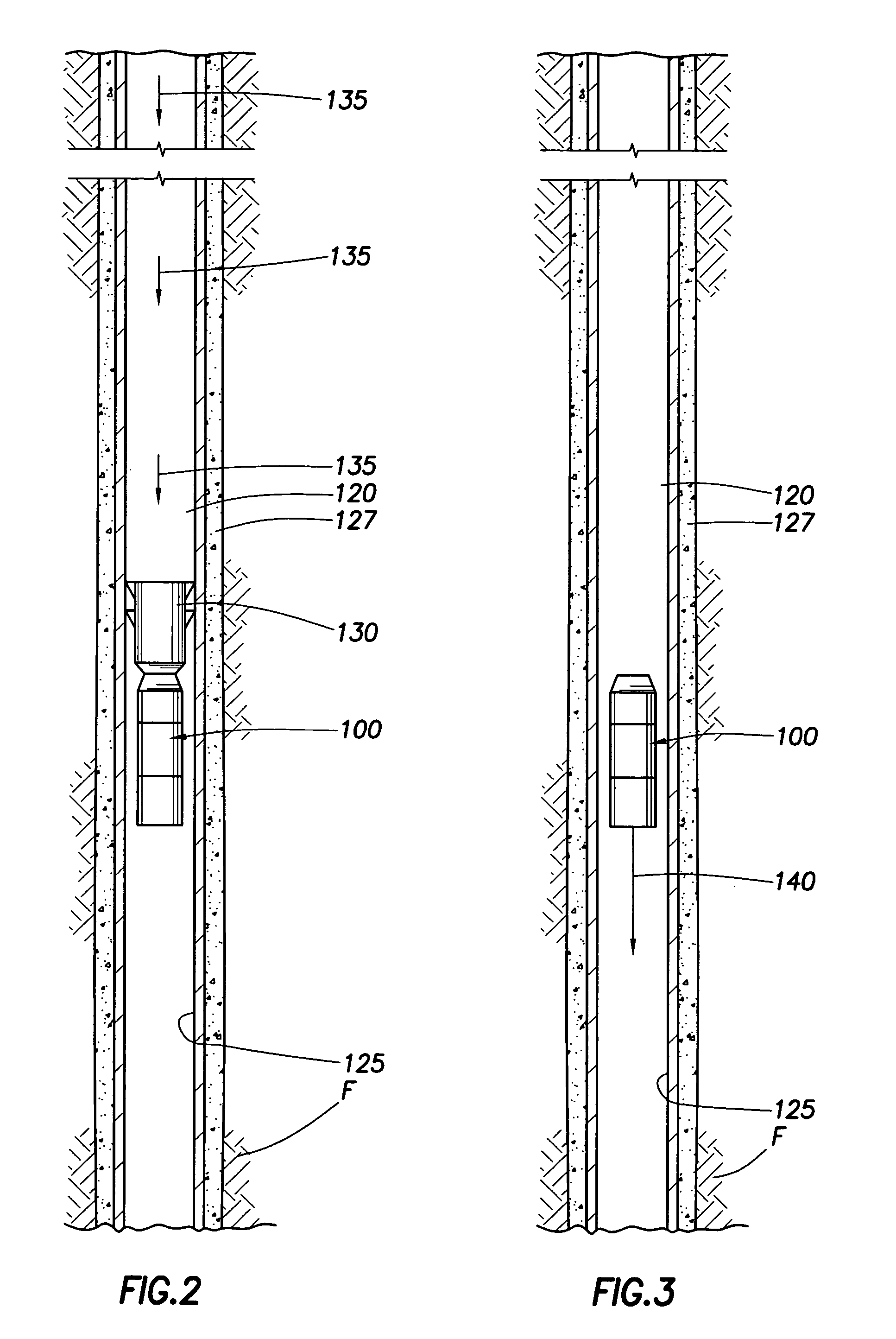

[0033] The present application relates to autonomous downhole tools that are moved at least a partial length along a well bore via an external force. In an embodiment, the autonomous downhole tool is moved along substantially the entire length of the well bore via an external force. In various embodiments, the external force is provided by a cable, by hydraulic pressure, by force of gravity, or by a combination thereof. In an embodiment, the autonomous downhole tool is not self-transportable via an onboard power supply. In an embodiment, the autonomous downhole tool is non-robotic. In an embodiment, the autonomous downhole tool does not provide its own locomotion. In an embodiment, the autonomous downhole tool is not self-propelling. In an embodiment, the autonomous downhole tool does not move within the well bore under its own power. In an embodiment, the autonomous downhole tool does not move within the well bore via traction with the well bore wall. In an embodiment, the autonomo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com