Eductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

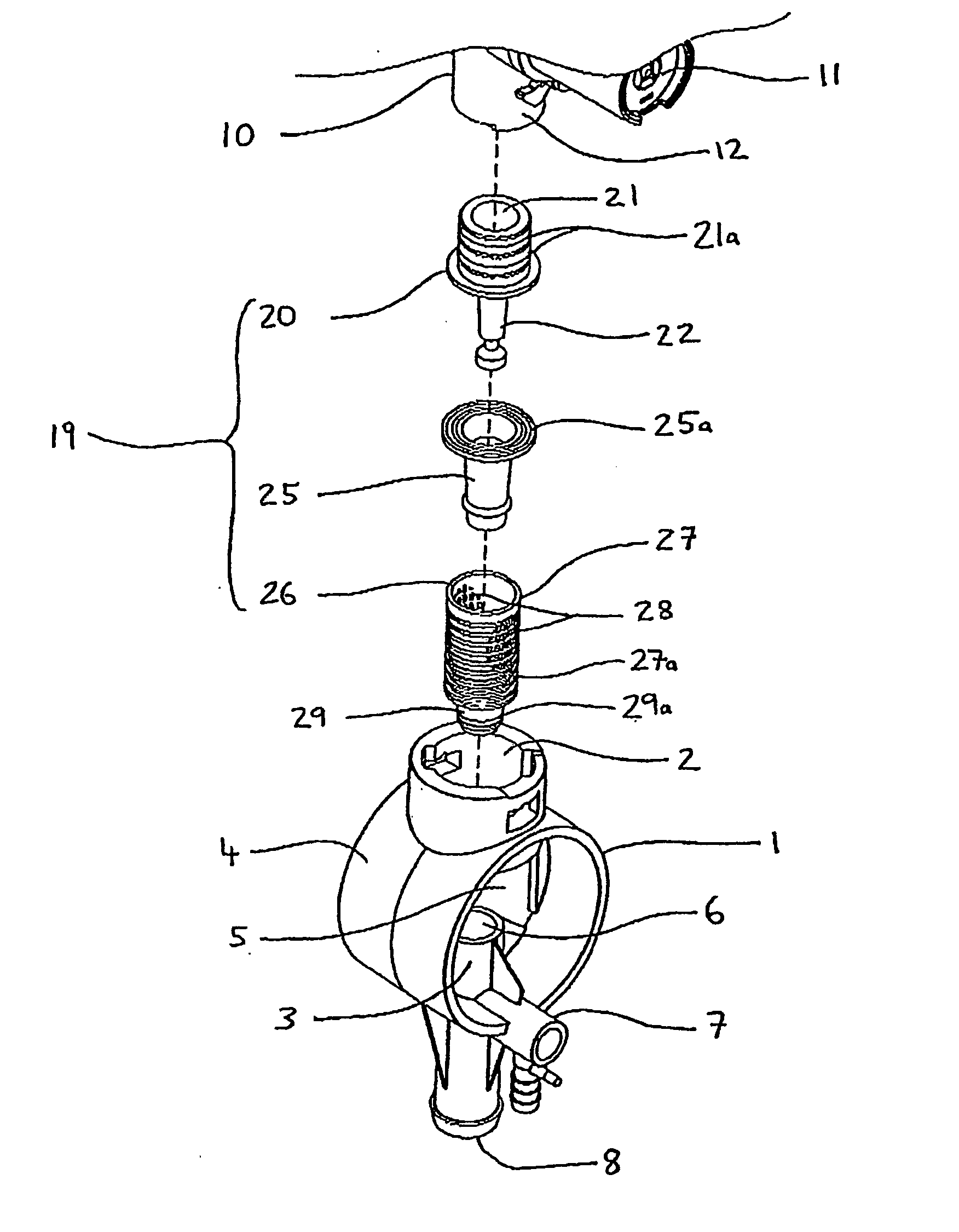

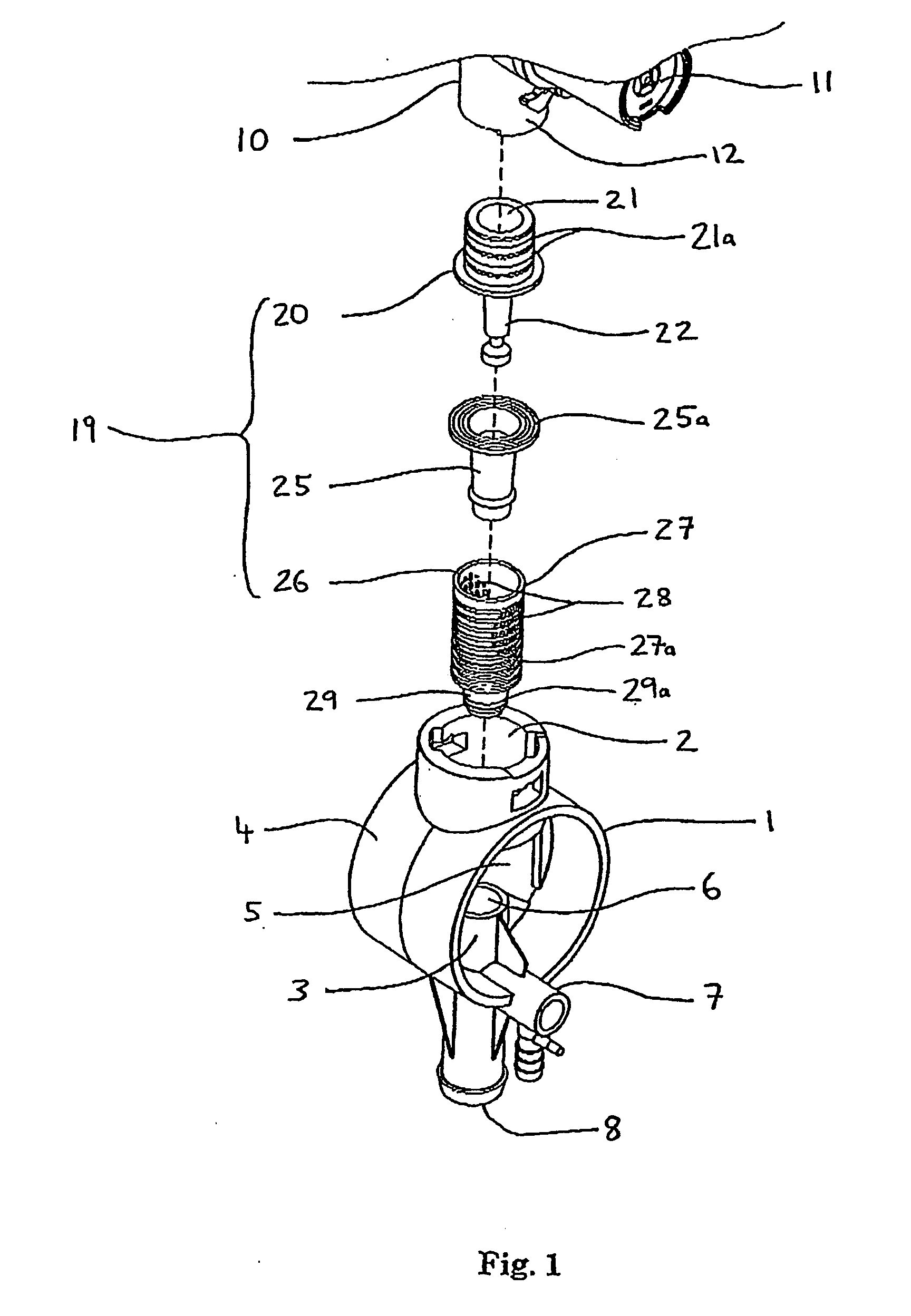

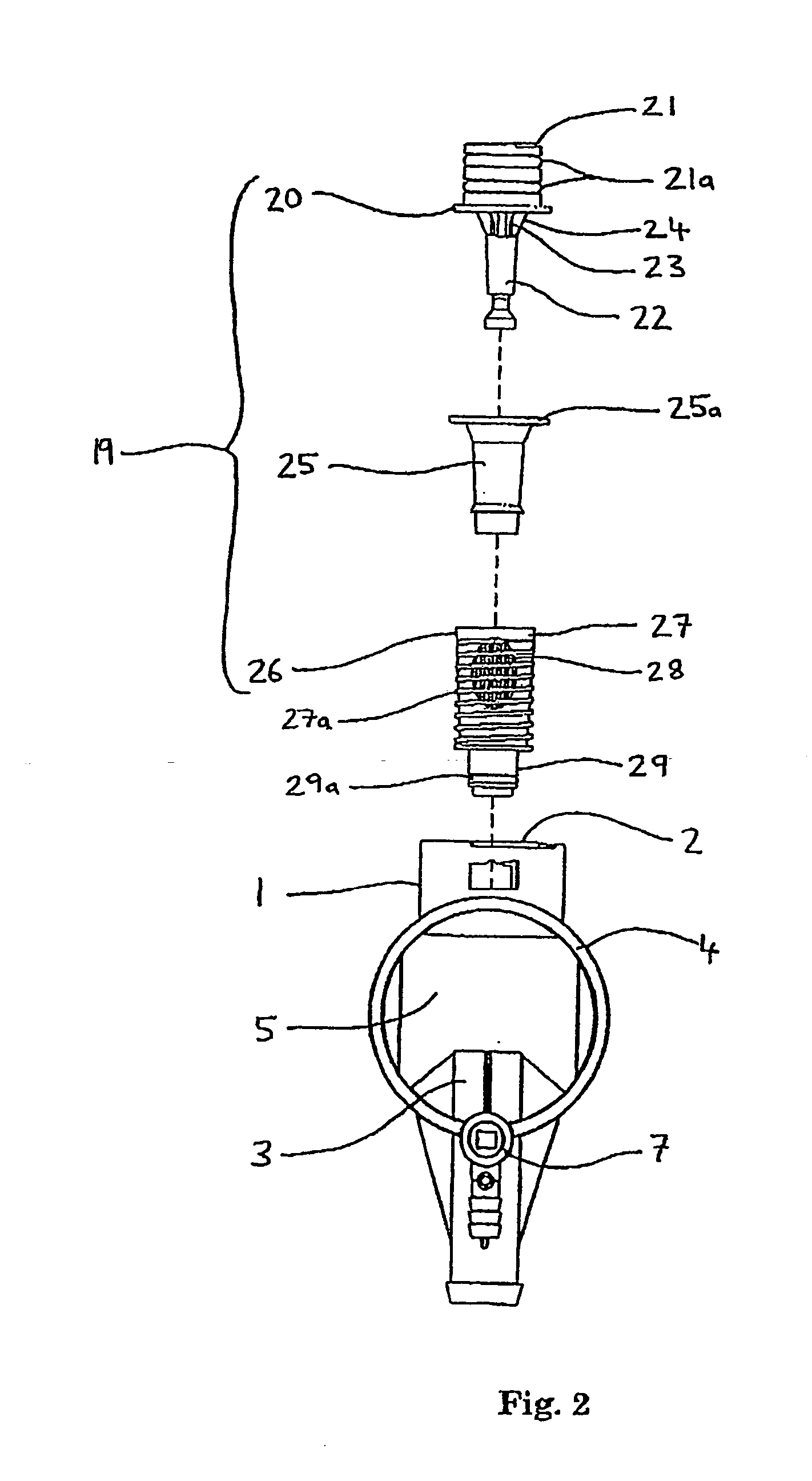

[0035] FIGS. 1 to 3 show an eductor 1 embodying the present invention, arranged in an upright position and comprising an inlet portion 2, a venturi structure 3, a main body 4 having an open ended horizontal cylindrical structure which defines an air gap 5 between the inlet portion 2 and the venturi structure 3. The venturi structure 3 comprises an inlet 6, a side passage 7 for delivering concentrated liquid to the venturi structure 3, and an outlet portion 8. The venturi structure 3 also comprises a venturi body (not shown) where mixing of the water and concentrated liquid occurs, and bypass passages (not shown) for liquid flow around the venturi body. The venturi structure 3 is conventional and need not be described in detail here.

[0036]FIG. 1 also partially shows a water supply conduit 10 which delivers water to the eductor 1. The conduit 10 includes a manually operable shut-off valve 11 in a conventional manner and a connection pipe 12 which is lockable into the inlet portion 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com