Container lid with removable seal layer

a technology of seal layer and container lid, which is applied in the field of containers with seal layer, can solve the problems of not providing a sufficient oxygen barrier to prevent rapid spoilage, accelerated degradation of food properties, and not readily apparent whether or not the lid has been tampered with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

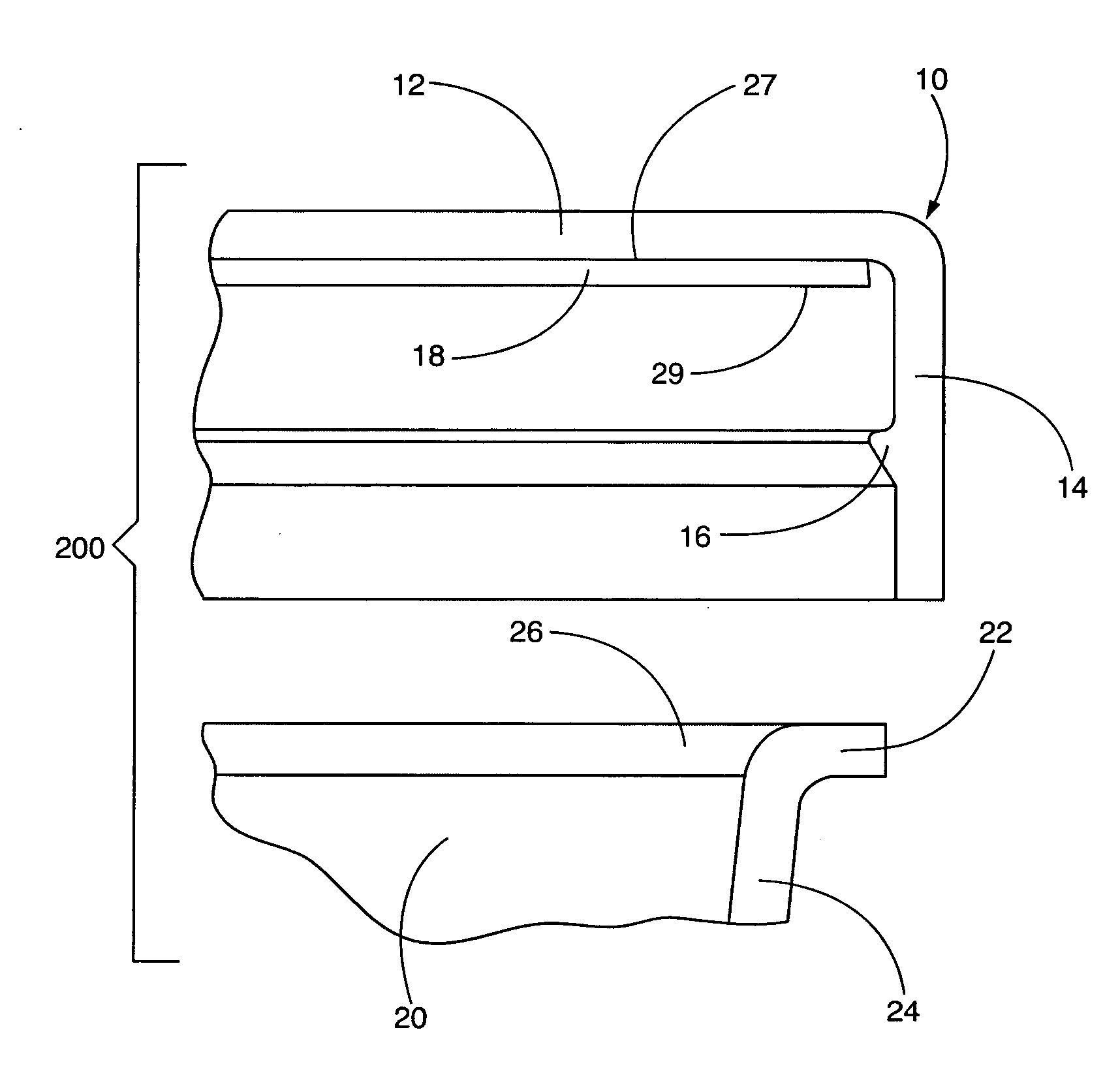

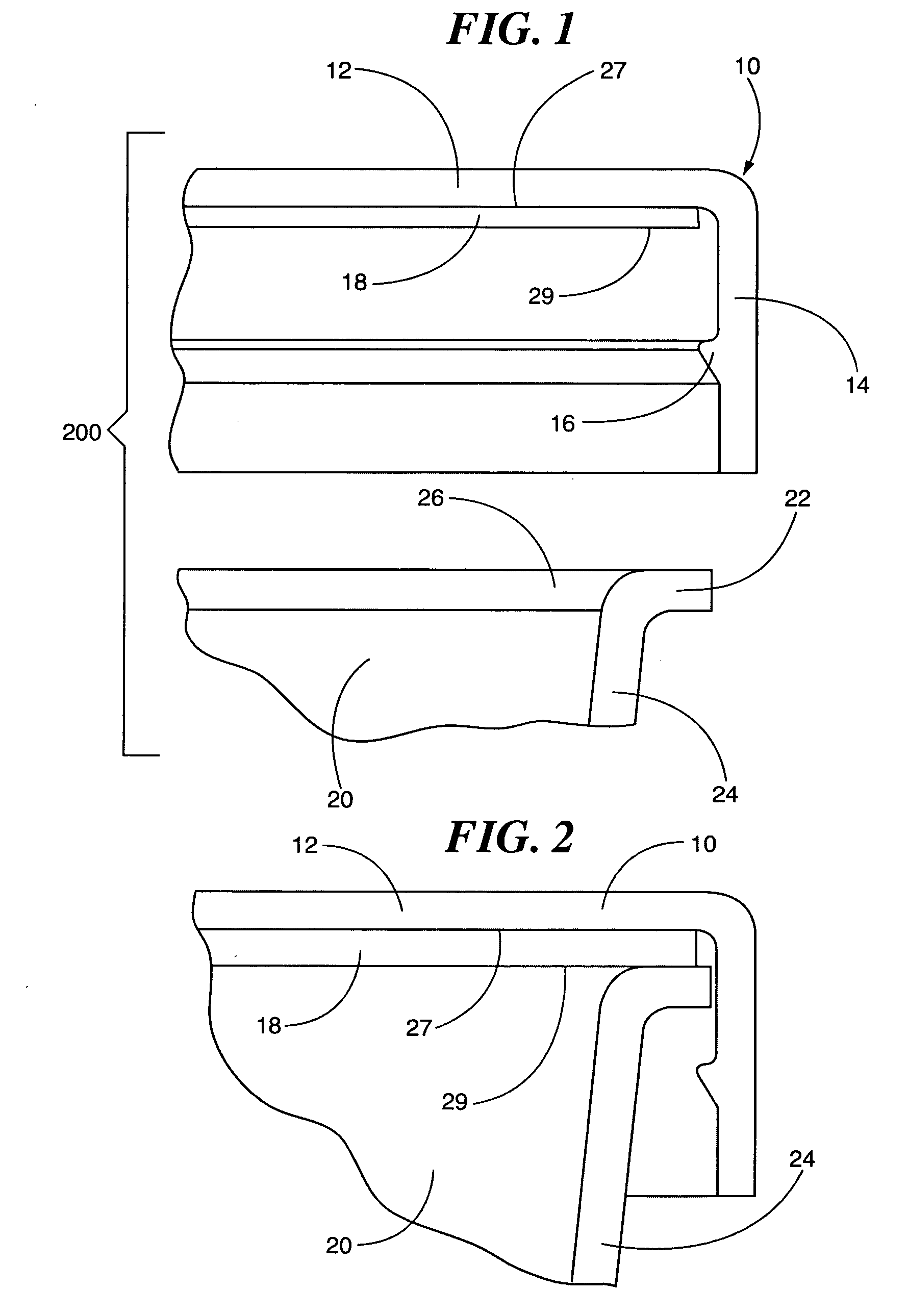

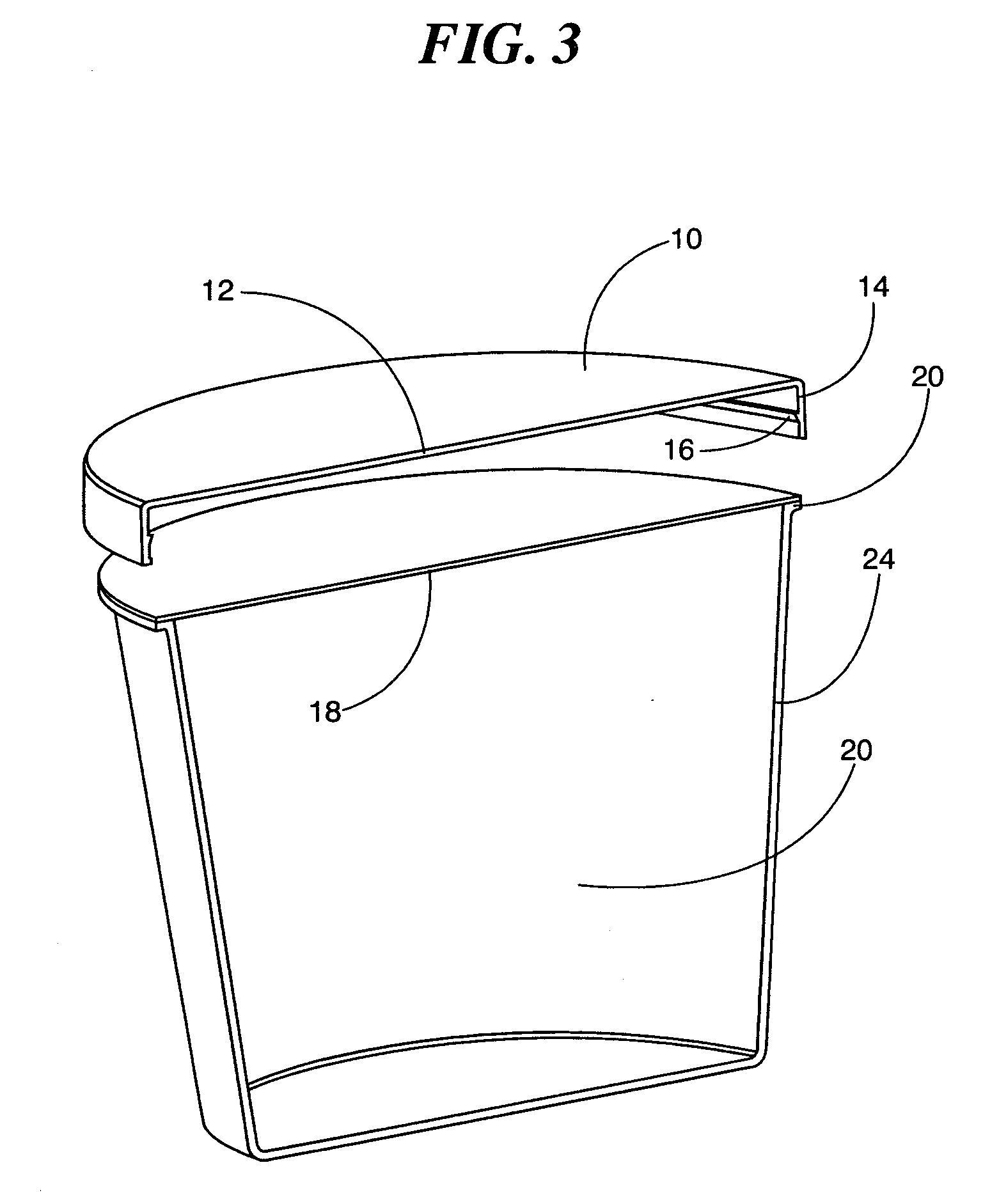

[0017] Reference is now made to FIG. 1 in which a container assembly 200, including a lid 10 and container 20, constructed in accordance with the invention, is provided. It should be known, that for the purposes of this explanation and in order to simplify the explanation, the term “membrane” is used generically to define the membrane / material layer, whether made from a film material, a foil material, a sheet of metal, or the like. Lid 10 includes a cover surface 12 and a sidewall 14 to form an enclosure. Cover surface 12 is sufficiently rigid to protect the interior of container 20, and support stacking of container 20. As is known in the art, the enclosure formed by cover surface 12 and sidewall 14 is dimensioned so that when disposed on a container 20 it covers container 20 to prevent debris from entering the interior and to prevent the contents of container 20 from escaping.

[0018] Container 20 is made of a material sufficiently rigid to maintain contents therein, whether liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com