Dental implant and method of insertion

a dental implant and implant technology, applied in the field of dental implants and methods of insertion, can solve problems such as fractures and breaks of implants, and achieve the effects of low stress isoelastic integration, high resistance to fatigue and breakage, and rapid and stable insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

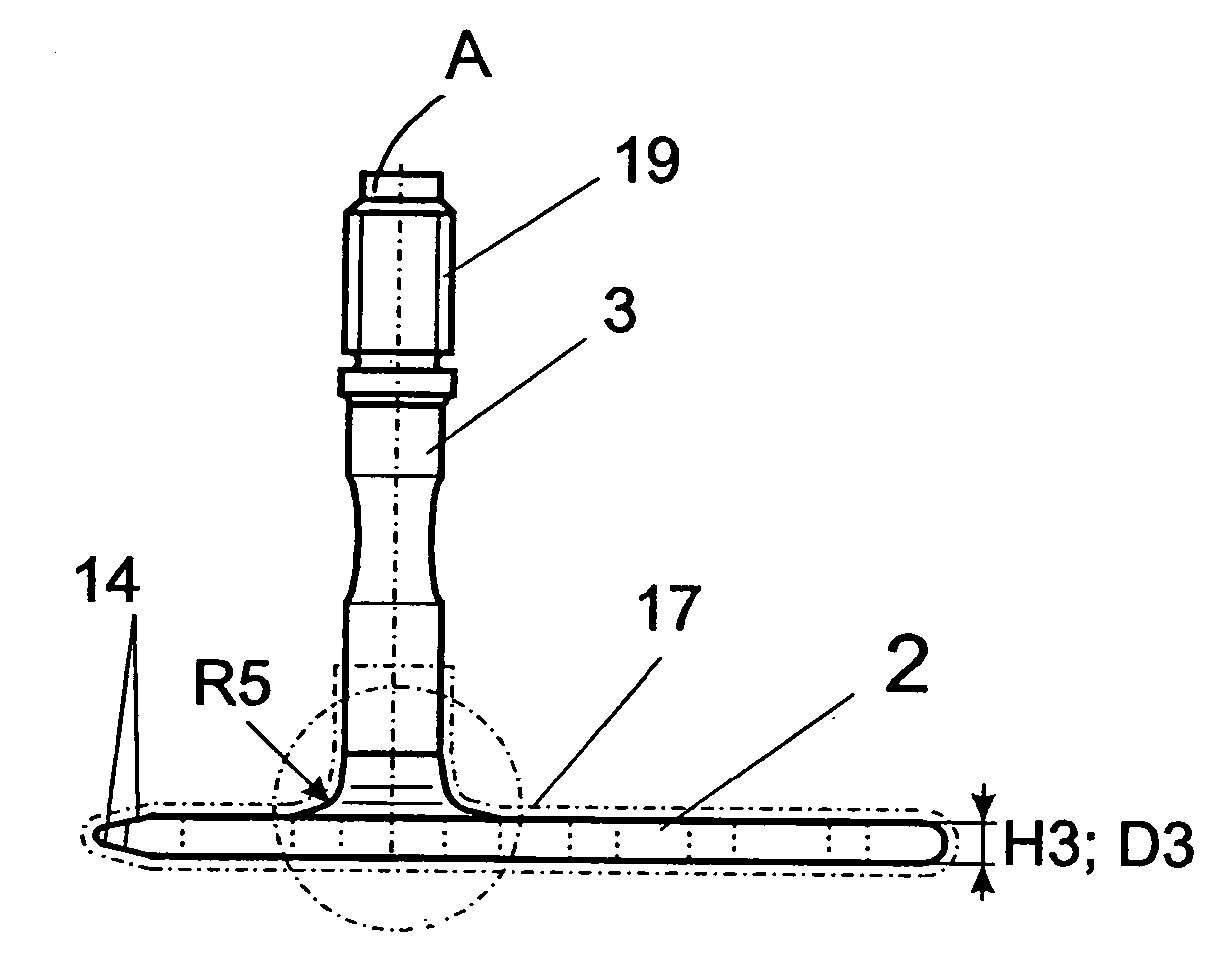

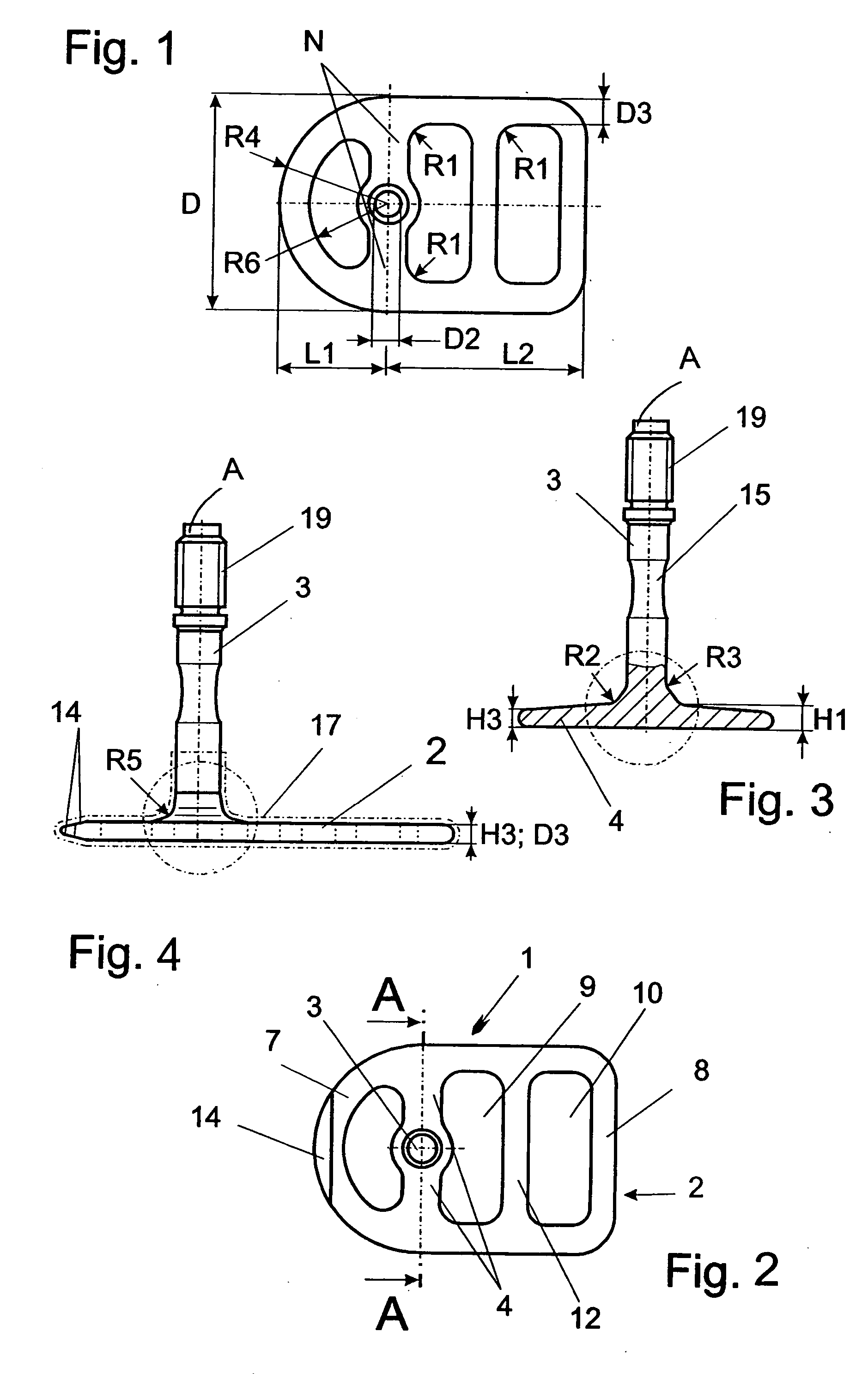

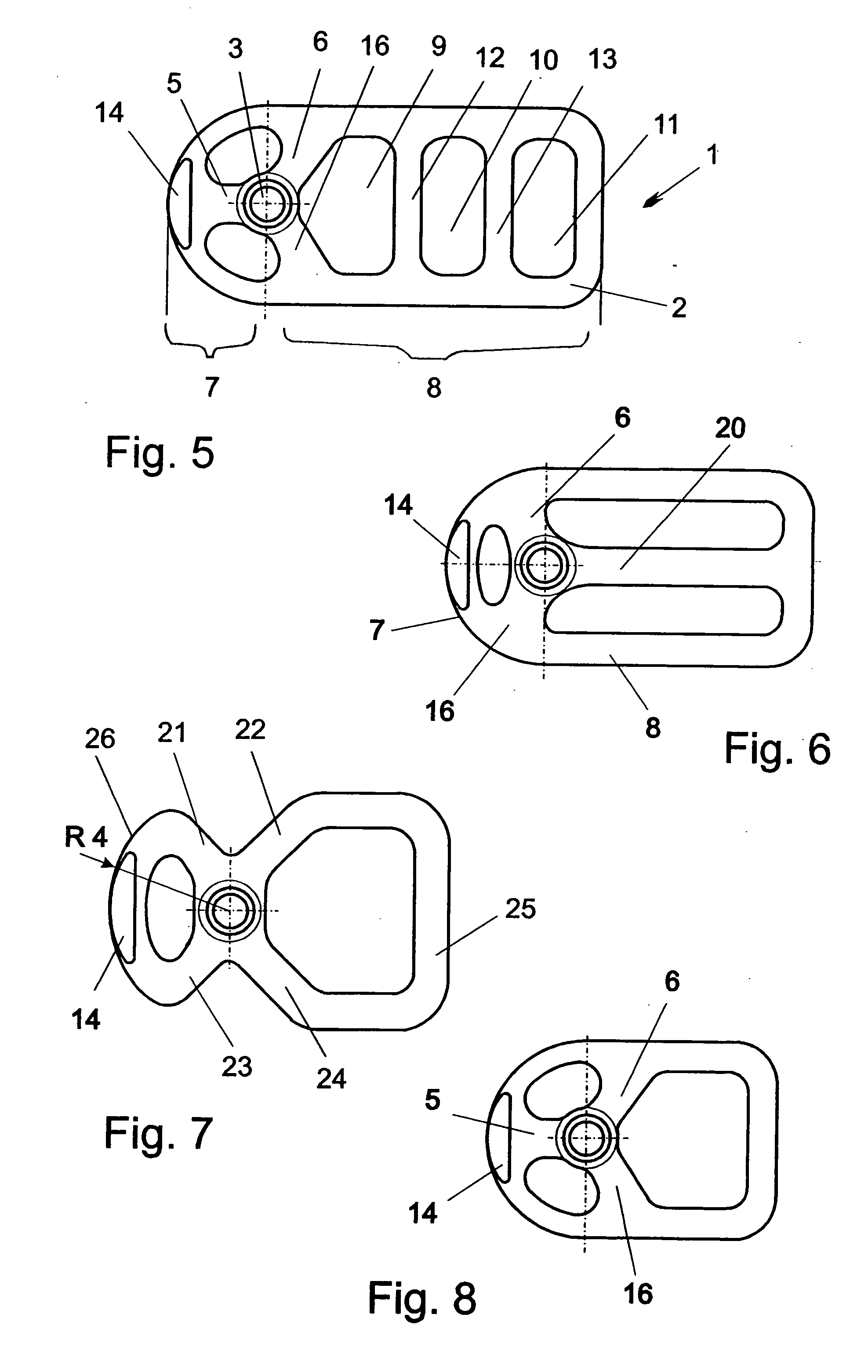

[0041] The first truly basally osseointegrated implants have been proposed in EP 0 935 949 A1, the disclosure of which is hereby incorporated by reference. They are different from implants, which either have a totally rigid design or transfer forces through expanded surfaces along the vertical post (e.g., FR 2,302,715). On the basis of these basally osseointegrated implants, it is possible to provide strategic implant positioning independently of the presence of a vertical bone supply and to provide basally osseointegrated implant prosthetic systems. For example, the annular design of the base part and the connection of the base part to the post through bars has the advantage that, if high forces are applied, the post can deflect slightly into the spongiosa, while the annular base remains solidly anchored in the compacta, supporting a lasting solid seating of the implant in the jaw bone. Further, the positioning of the post outside the center of the base part, in the center of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com