Striking surface of golf club heads

a golf club head and striking surface technology, applied in the field of golf club head striking surface, can solve the problems of awkward appearance of the rough surface and the inability to make grooves on the striking surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

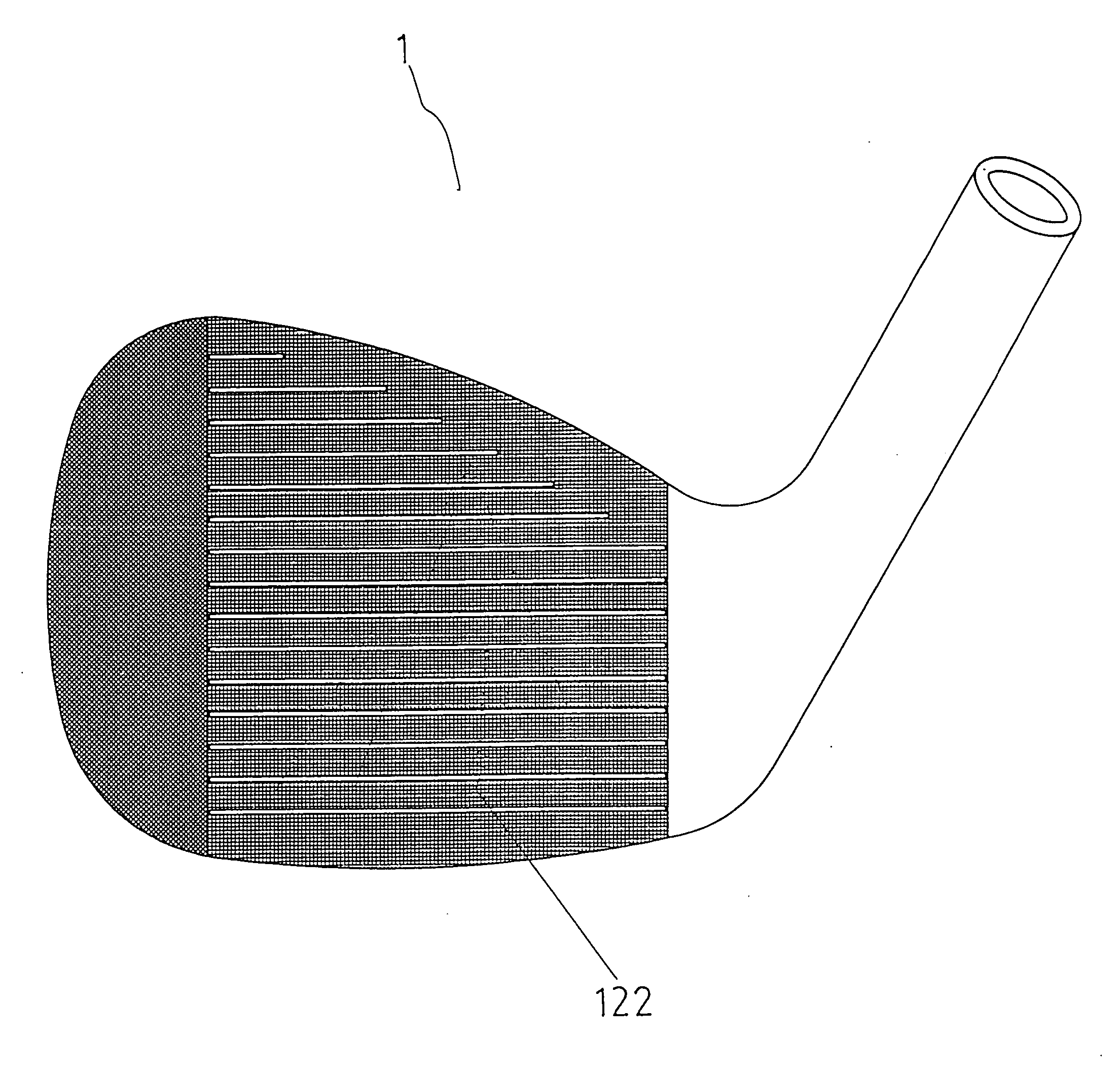

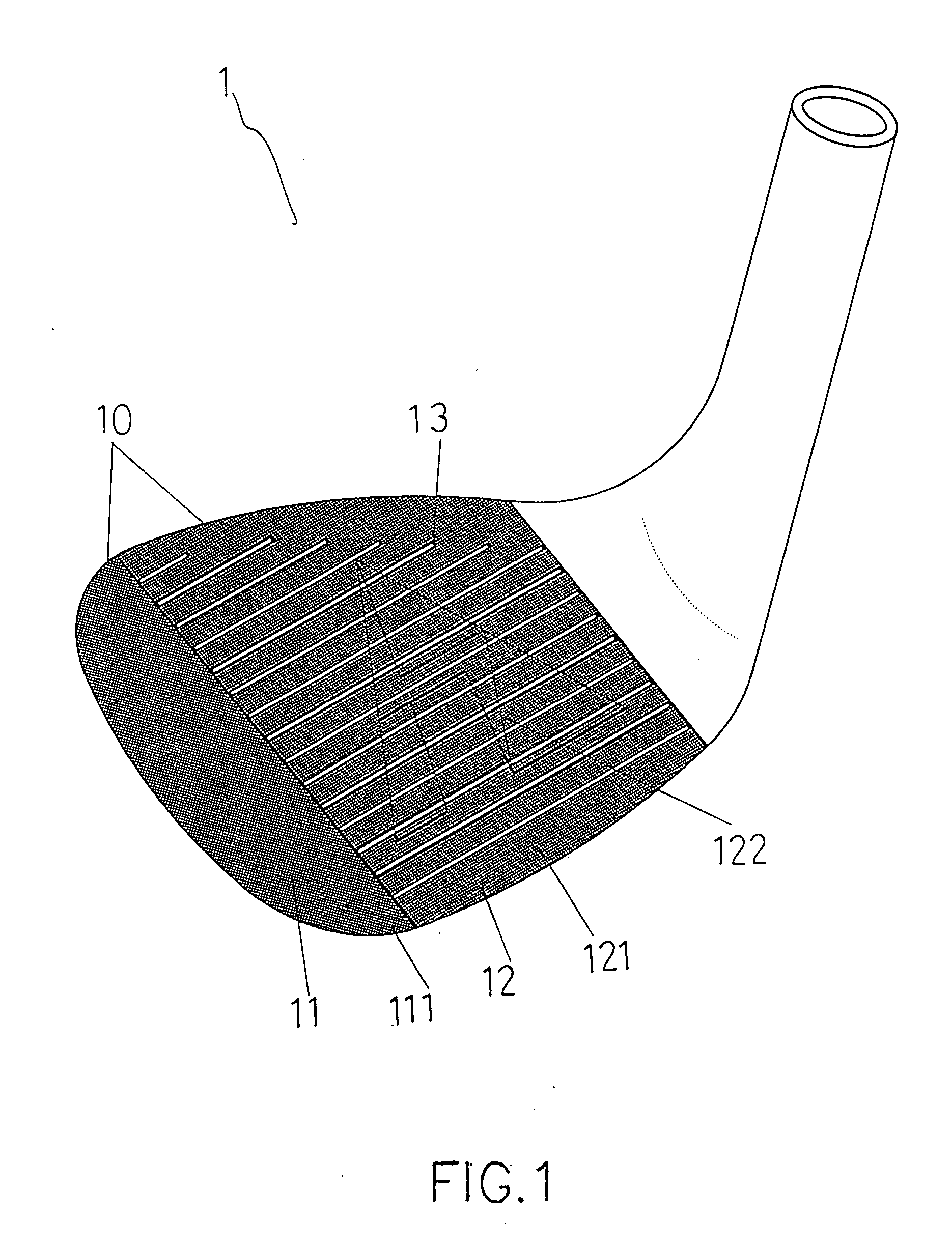

[0013] Referring to FIG. 1, the golf club head 1 of the present invention comprises a striking surface 10 composed of a toe area 11 and striking area 12. The toe area 11 includes cruciform patterns 111 made by CNC and the striking area 12 includes parallel grooves 13 and at least one pattern 121 made by electro-etching. An identification pattern 122 such as a logo made by electro-etching is defined in the striking area 12.

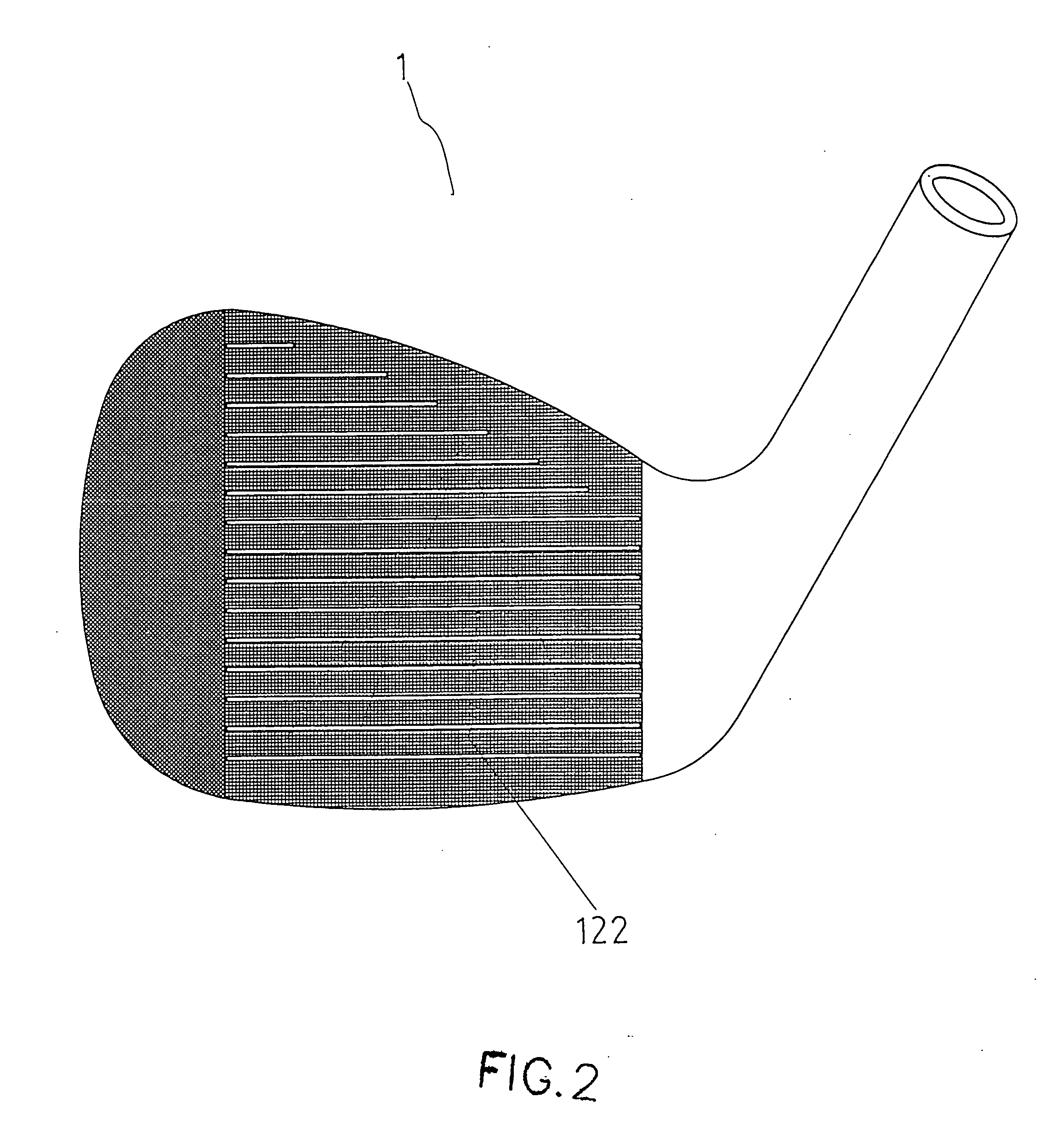

[0014] As shown in FIGS. 2 and 3, the identification pattern 122 is hidden when viewed perpendicularly to the striking surface and is visible when viewed from an angle to the striking surface 10.

[0015] The golf club head 1 requires only one time of machining process such that the manufacturing cost is less than that of the conventional golf club heads. The striking surface 10 made by way of electro-etching provides a non-slippery surface and the golf ball can be delivered to a far distance. The post-rotation of the golf ball is satisfied. The identification patte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com