Electronics cabinet with an air-to-air heat exchanger mounted to the outside of the cabinet

a technology of heat exchanger and electronic cabinet, which is applied in the direction of cooling/ventilation/heating modifications, lighting and heating apparatus, and standard racks/cabinets. it can solve the problems of reducing the useful life of the equipment inside the cabinet, generating more heat than basic pots cards, and replacing an entire door, so as to reduce the amount of time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

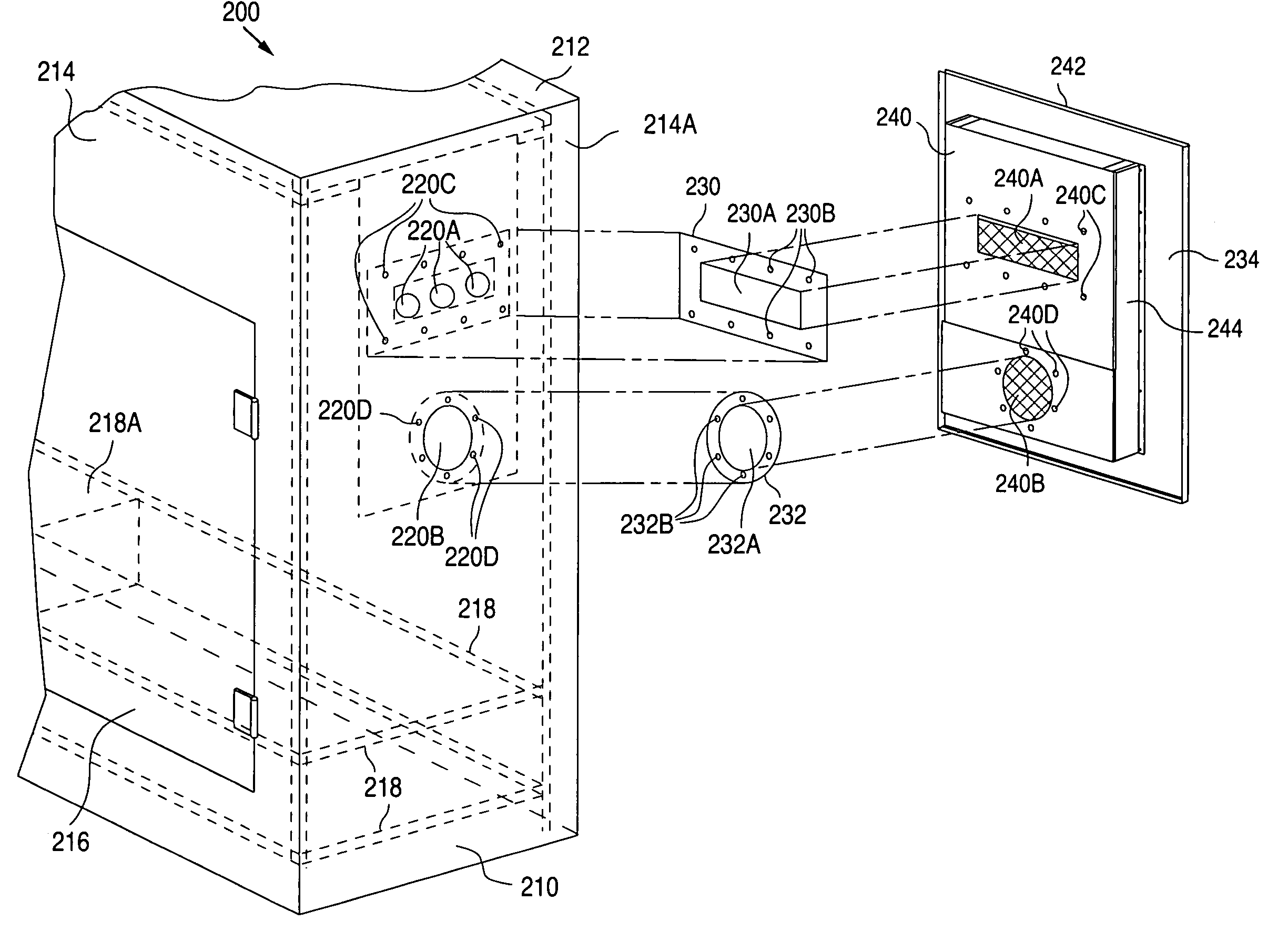

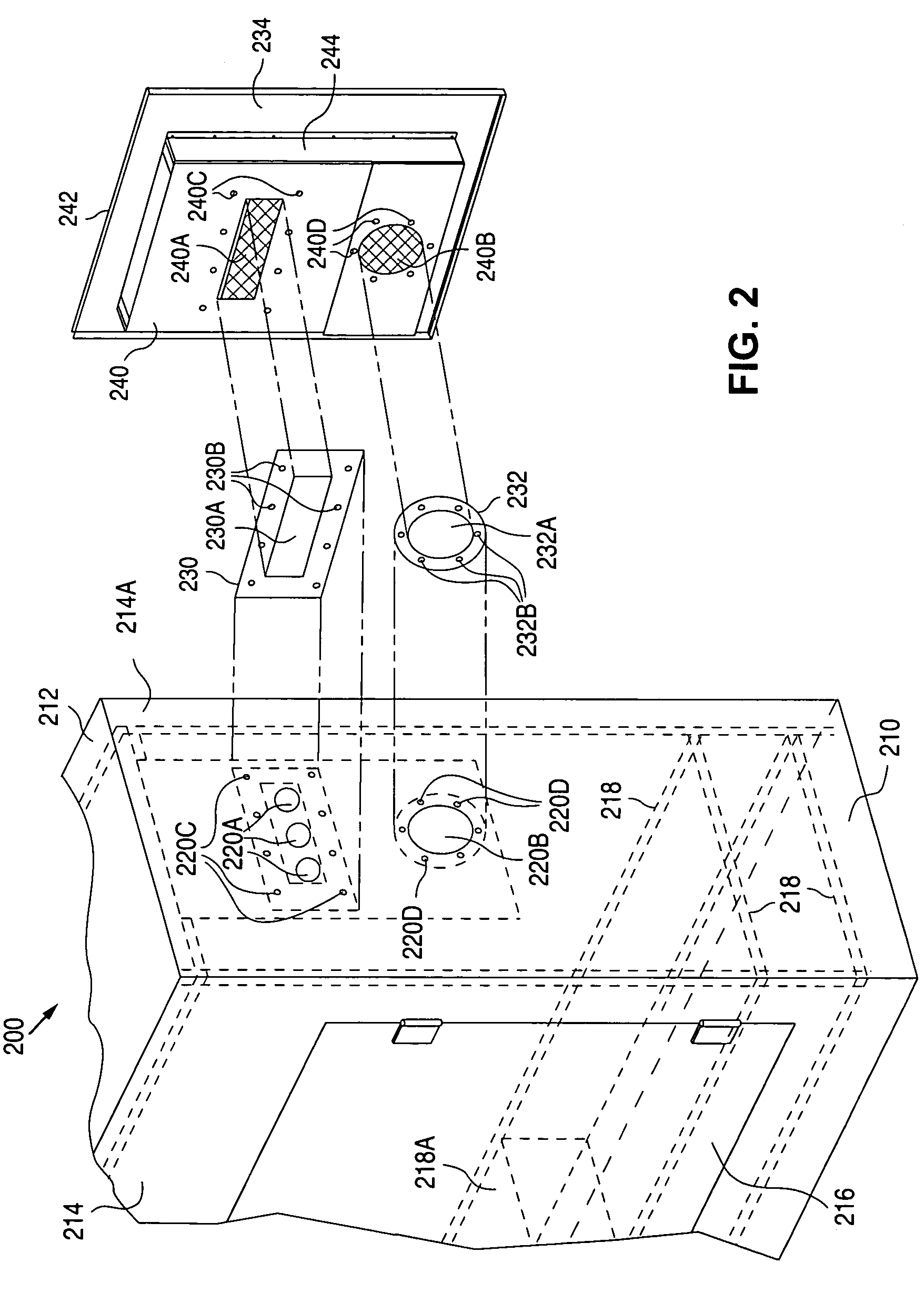

[0025]FIG. 2 shows a perspective view that illustrates an example of an electronics cabinet 200 in accordance with the present invention. As described in greater detail below, the present invention eliminates the difficulties normally associated with retrofitting an existing cabinet to include an air-to-air heat exchanger by attaching the heat exchanger to the exterior of the cabinet.

[0026] As shown in FIG. 2, cabinet 200 includes a bottom surface 210, a top surface 212, a number of side wall surfaces 214, including a mounting side wall surface 214A, that are connected to bottom surface 210 and top surface 212, and a door 216 that is connected to a side wall surface 214 via hinges or other structures that allow an interior of cabinet 200 to be exposed.

[0027] When door 216 is closed, the interior of cabinet 200, as defined by bottom surface 210, top surface 212, side wall surfaces 214, and door 216, becomes an air tight and water tight enclosure. In addition, cabinet 200 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com