Cup holder

a technology for cups and cups, applied in the field of cups, can solve the problems of increasing not only the number of parts, but also the steps required for assembly, and reducing the cost of construction, so as to improve the user experience and reliability of the unit, reduce the required machining precision, and increase the design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

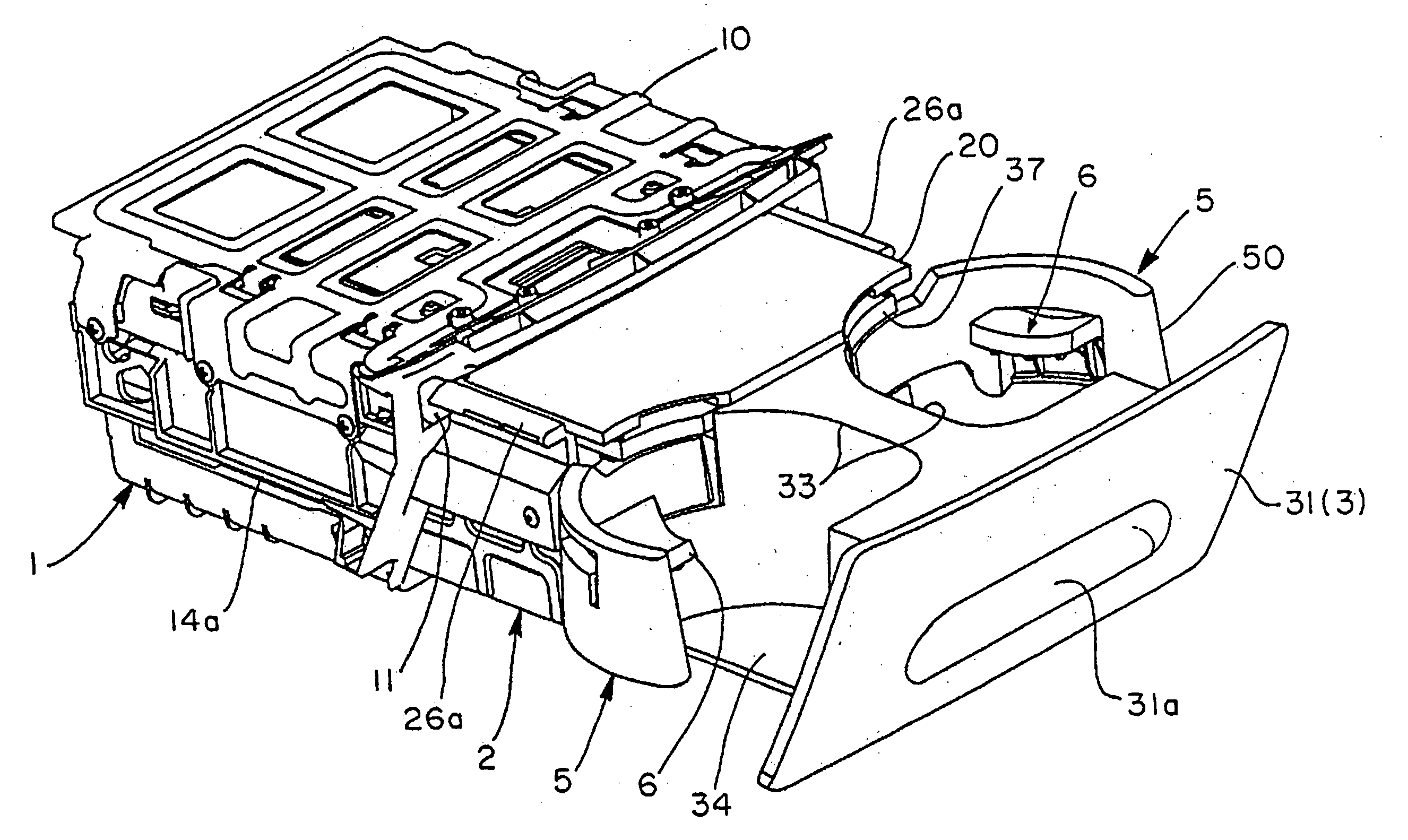

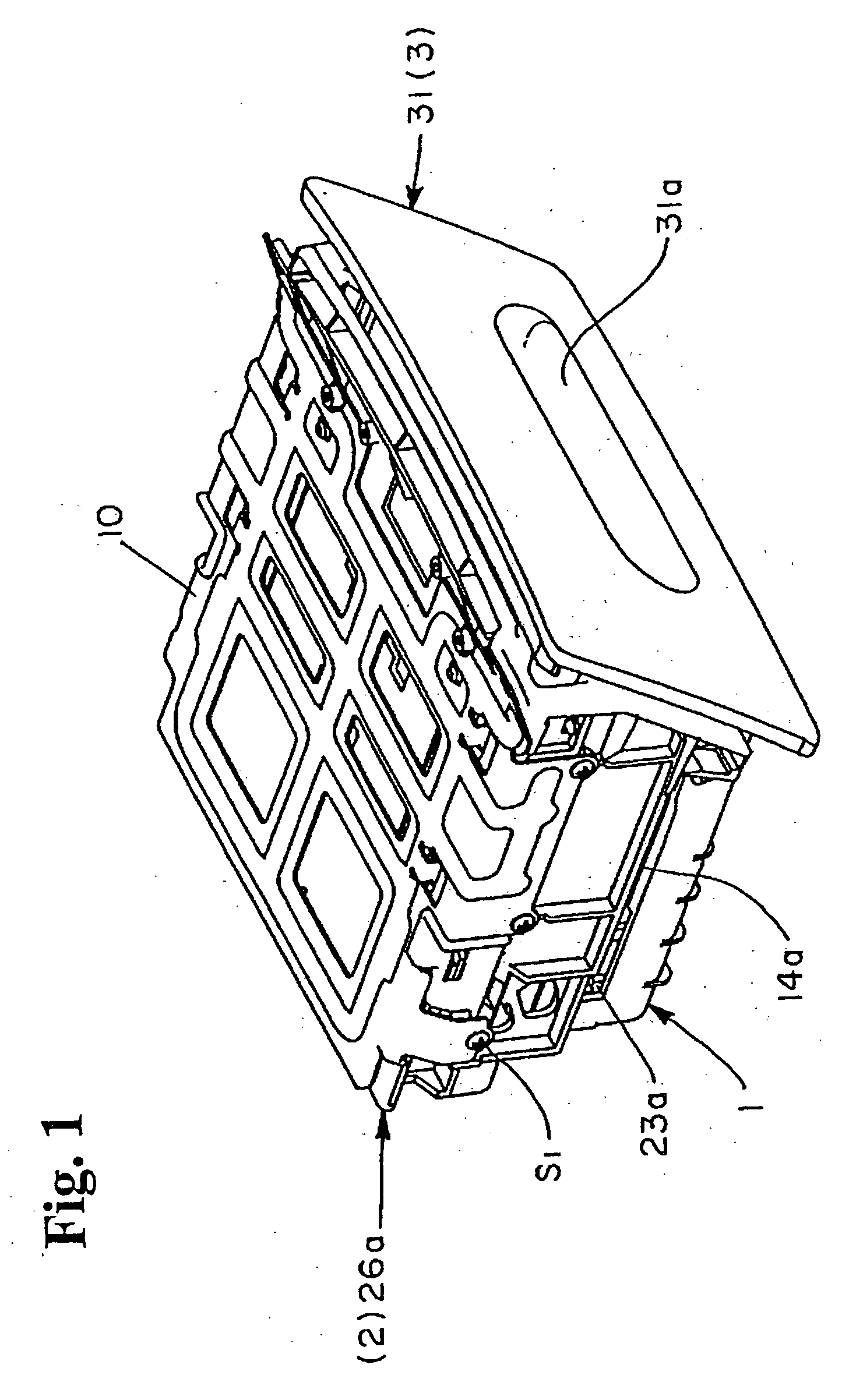

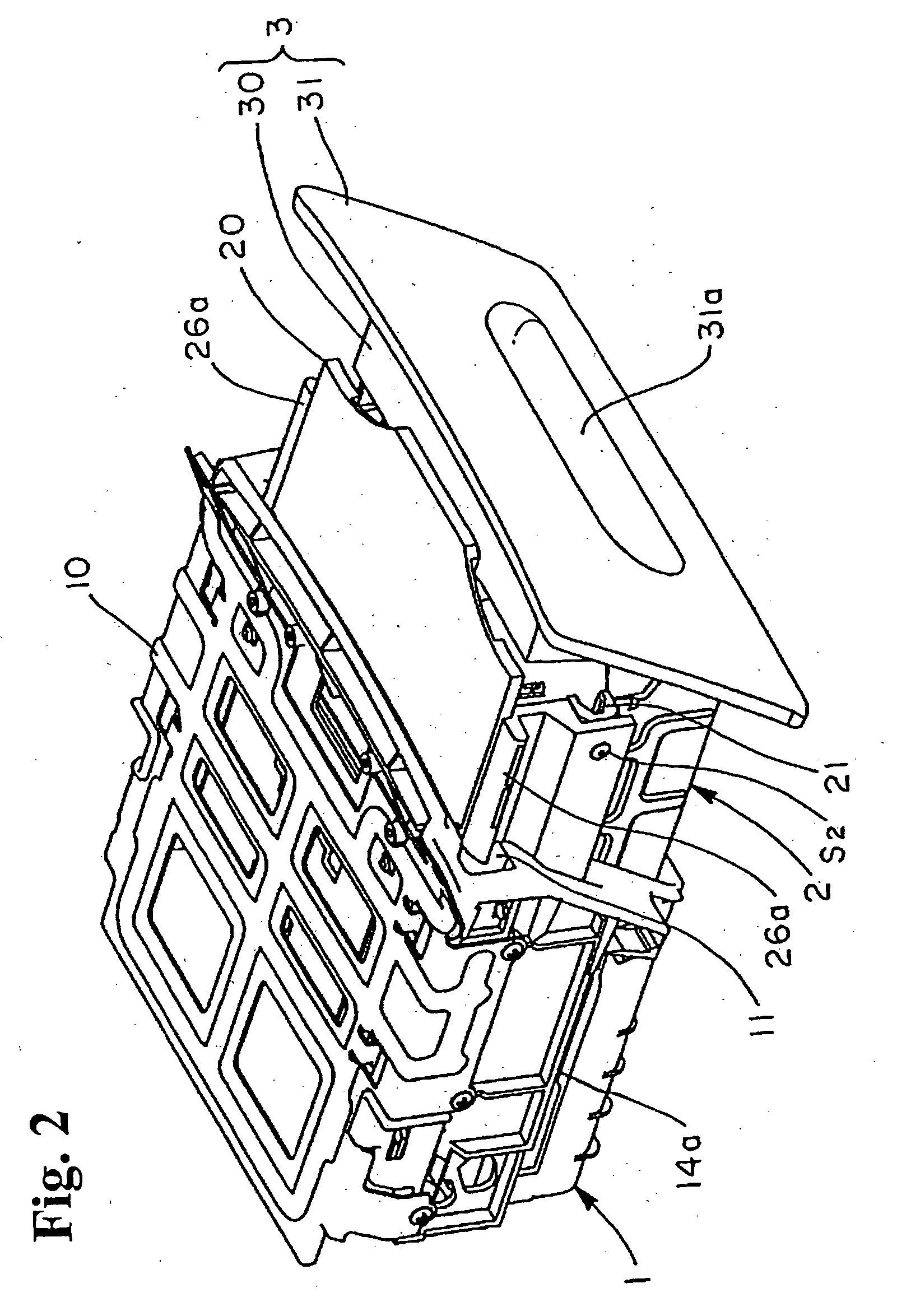

[0041] Embodiment of the present invention will be explained based on the drawings. FIGS. 1-3 are schematic views of a cup holder unit in various states. FIGS. 4-6 and 8(a)-8(c) show the components of the unit. FIGS. 7, 9(a) and 9(b) show the relationship between the side supporter and the sub-holder. FIGS. 10-15 show the switching operation of the unit, and FIGS. 16(a) and 16(b) schematically compare the sub-holder of the present invention with that of a conventional unit. In the following explanation, the unit's structure will be discussed in detail, and then how to use the unit, or the operation, will be mentioned.

Unit's Structure

[0042] A cup holder unit in this embodiment is installed in an instrument panel or a console of various types in an automobile, for example, and the main components include a fixed outer case 1, a movable inner case 2, a main holder member 3 for holding a container, a connecting member 4 pivotally supported in the inner case 2, side supporters 5 pivot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com