Flexible bathtub waste pipe assembly for bathtubs and the like

a waste pipe and bathtub technology, applied in the field of bathtub waste pipe assembly, can solve the problems of increasing the cost of the assembly, increasing the complexity of installation, and difficult installation of rigid pipes, and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

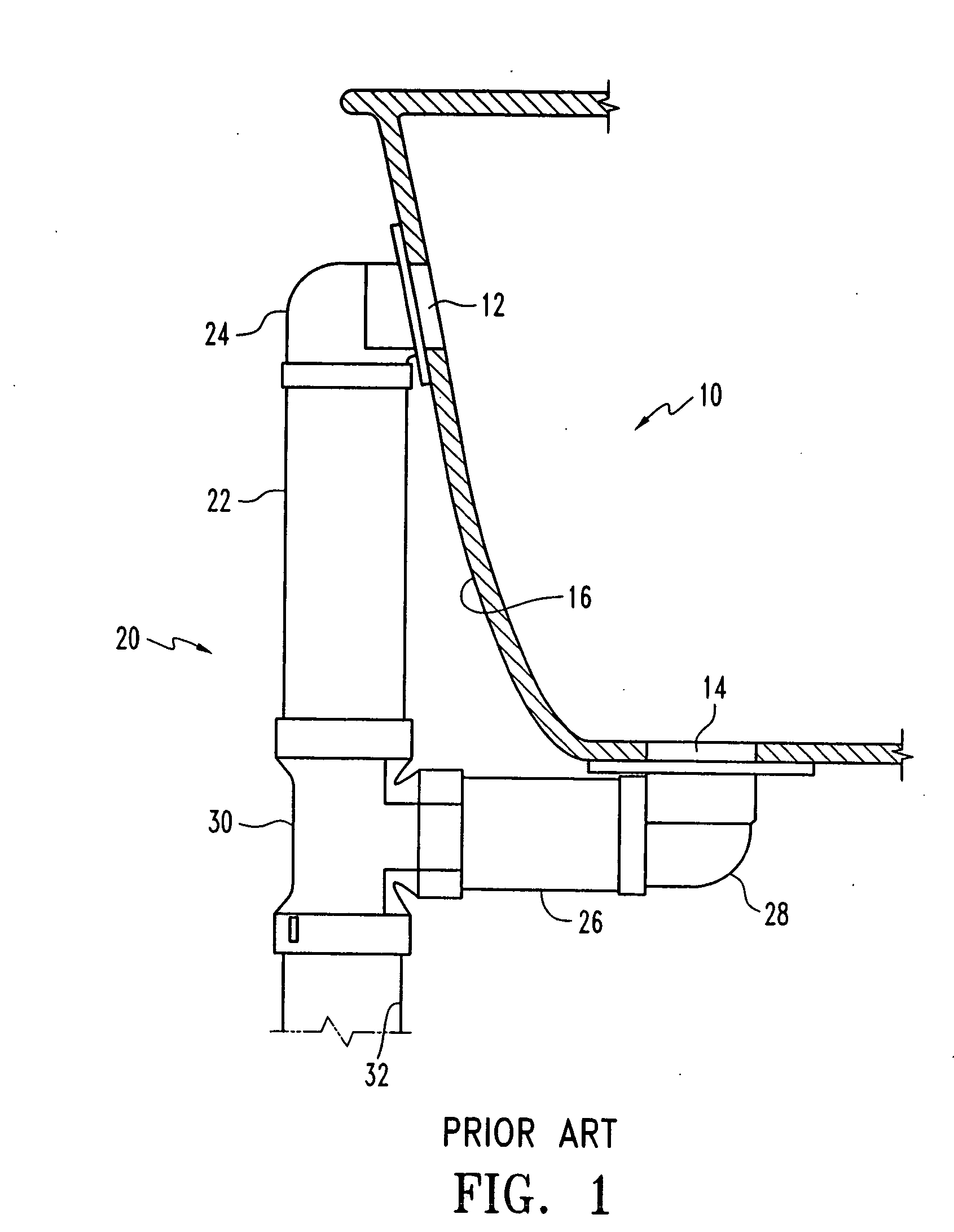

[0012] With reference to FIG. 1, a conventional bathtub 10 has an upper overflow drain 12 and a lower drain 14. The upper overflow drain 12 is located at one end 16 of the bathtub 10 for draining overflow fluids from the bathtub 10. The lower drain 14 is located in the bottom of the bathtub 10 for draining fluids from the bottom of the bathtub 10.

[0013] A conventional prior art rigid waste pipe assembly 20 has an upper rigid pipe 22 oriented in a vertical direction. The pipe 22 is connected to the bathtub upper overflow drain 12 via an upper rigid connector 24. The pipe assembly 20 also has a lower rigid pipe 26 oriented in a horizontal direction. The pipe 26 is connected to the lower drain 14 via a lower rigid connector 28. The pipe 22 and the pipe 26 are joined at a rigid three-way connector 30. The connector 30 receives fluid from both the upper overflow drain 12 and lower drain 14, and directs the fluid to a bottom outlet 32.

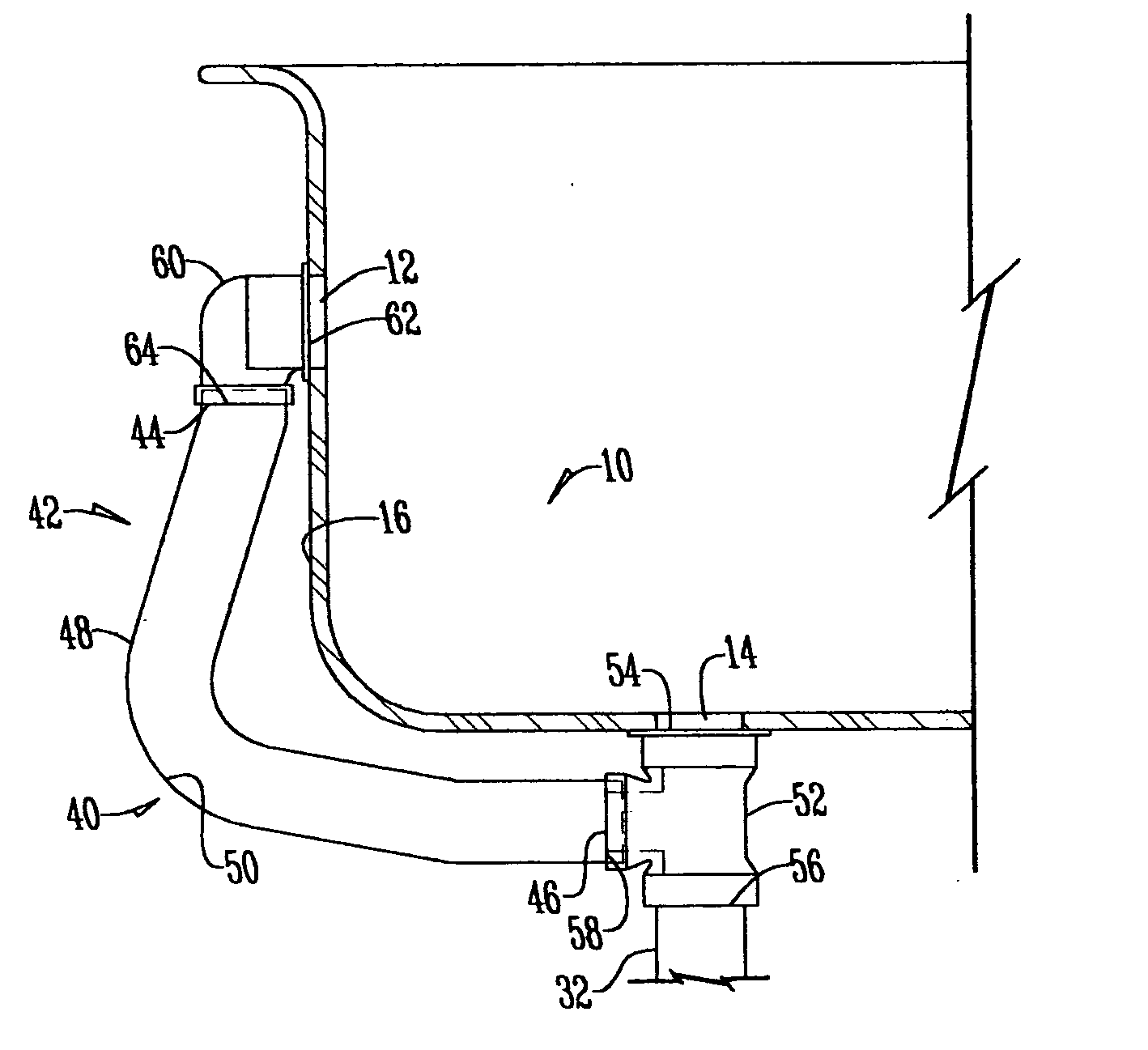

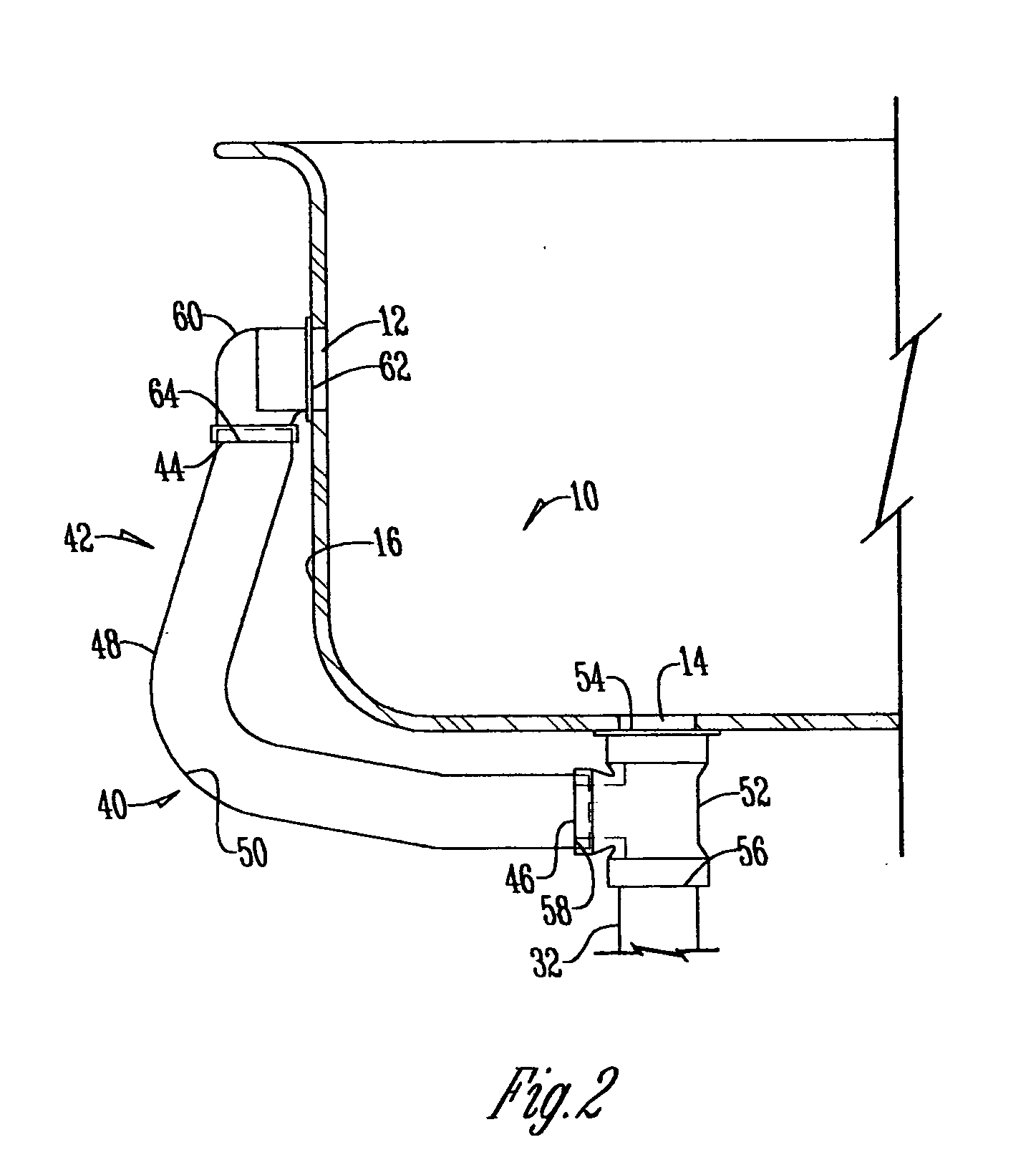

[0014] Referring now to FIG. 2, a bathtub waste pipe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap