Extensible laminate having elastics of differing elastic properties

a technology of elastics and elastics, applied in the field of elastics of different elastic properties of elastics in laminates, can solve the problems of product design limitations, unpredictability of material webs, and inconvenient use of laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

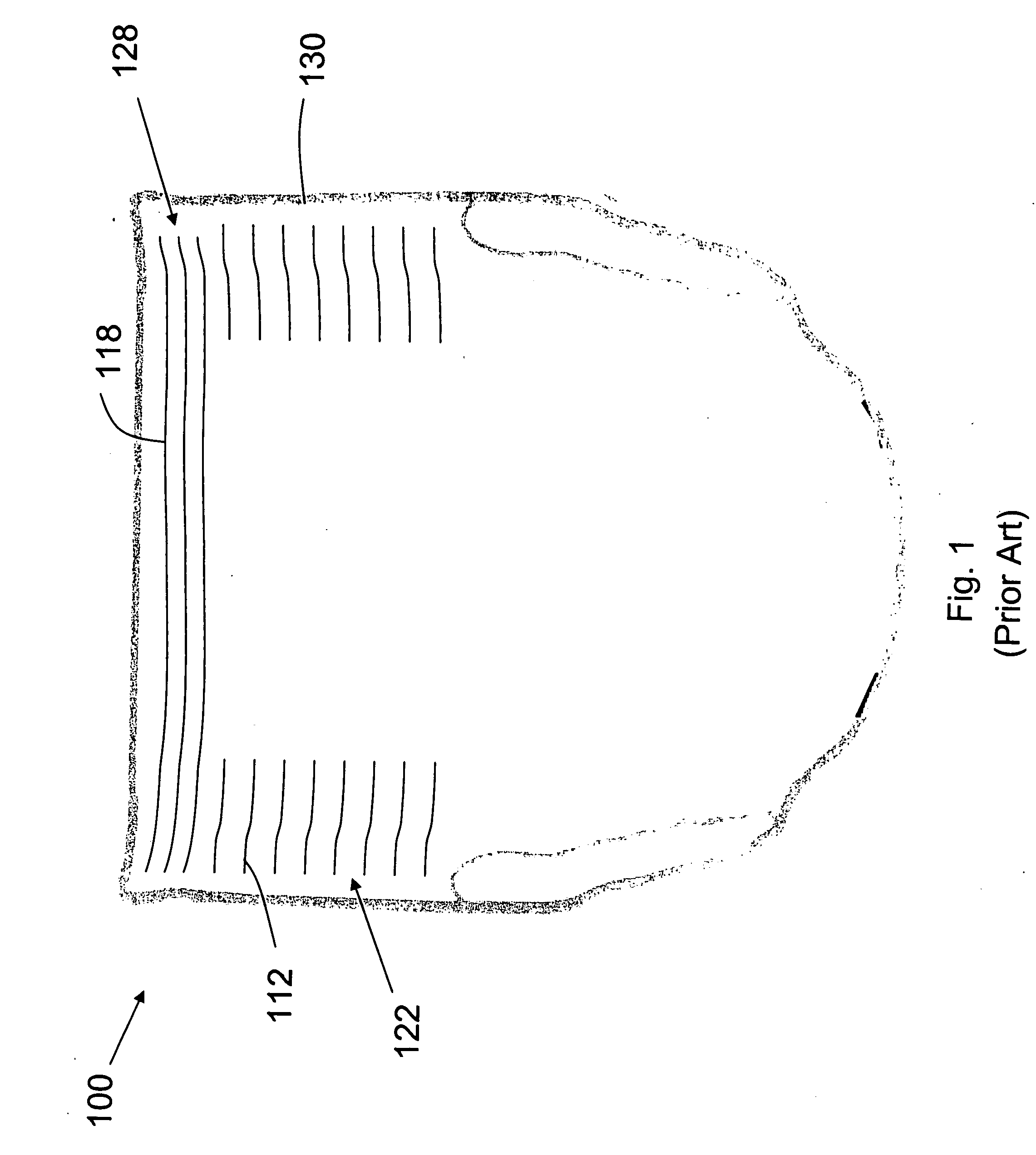

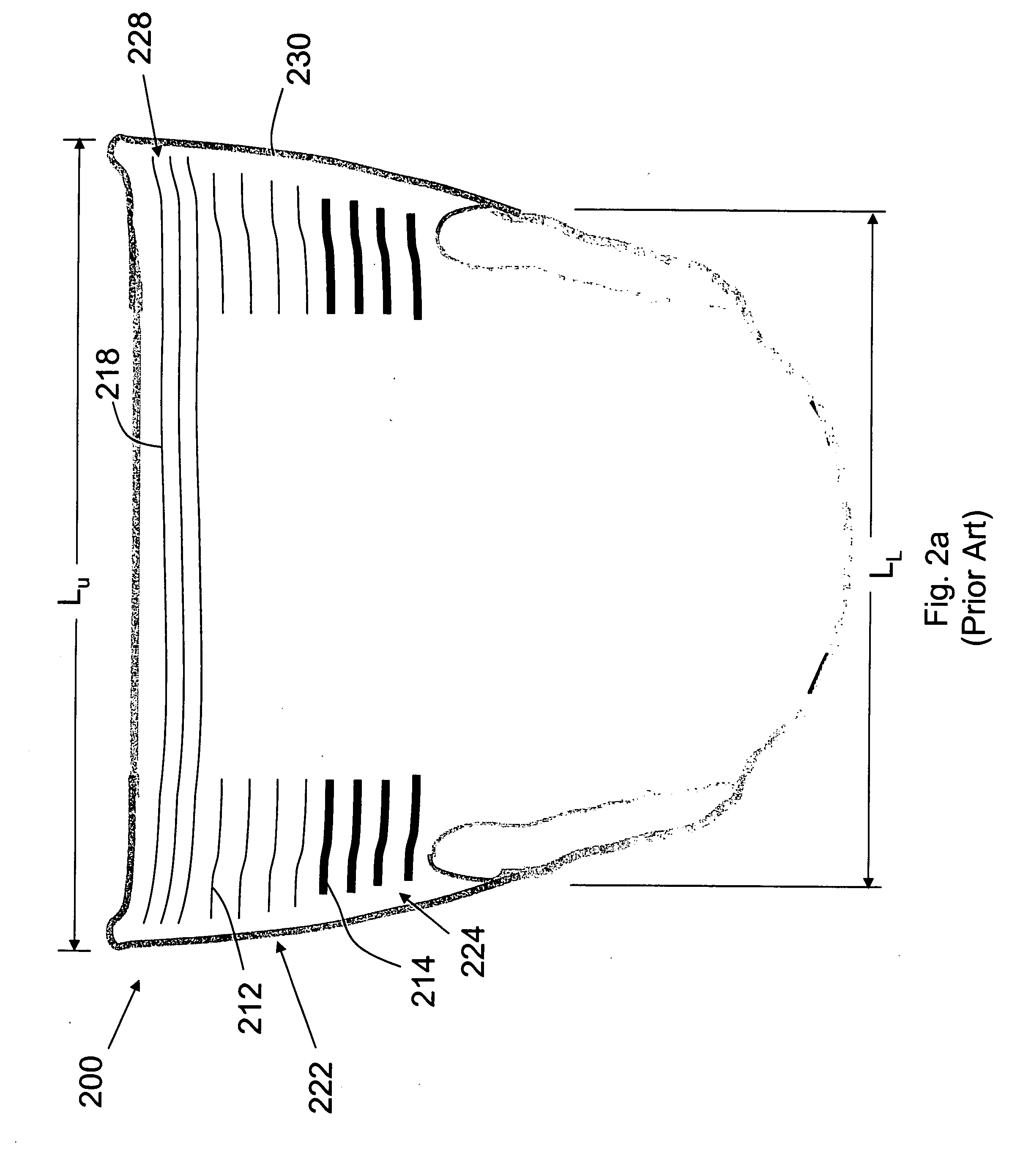

[0082]FIG. 14 depicts an exemplary laminate 6080 within the prior art. Laminate 6080 may be constructed from elastics (e.g., made of a block copolymer supplied by Kuraray under the trade name KL 2014) tensioned and sandwiched between two layers of 10 gsm SMS polypropylene nonwoven (e.g., supplied by Avgol). An adhesive (not shown) may be used to laminate the two layers together (e.g., 3 gsm; Findley H2031). Upon relaxation of the tension in the elastics (e.g., 6012, 6014), the nonwoven will form gathers 6015.

[0083] More specifically, laminate 6080 may be constructed of a series of first elastics 6012 and a series of second elastics 6014. Elastics 6012 have an elastic basis weight of about 20 gsm when measured in the relaxed laminate. Elastics 6014 have an elastic basis weight of about 70 gsm when measured in the relaxed laminate. Elastics 6012, 6014 are similarly spaced apart 2.5 mm from each other.

[0084] Assuming that elastics 6012 were produced under a process strain of 4.0 (i.e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Equilibrium | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com