Amusement ride

a technology for roller coasters and rides, applied in the field of roller coasters, can solve the problems of not being able to rotate the roller coaster, not being able to provide free fall, retrograde motion or helical motion,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

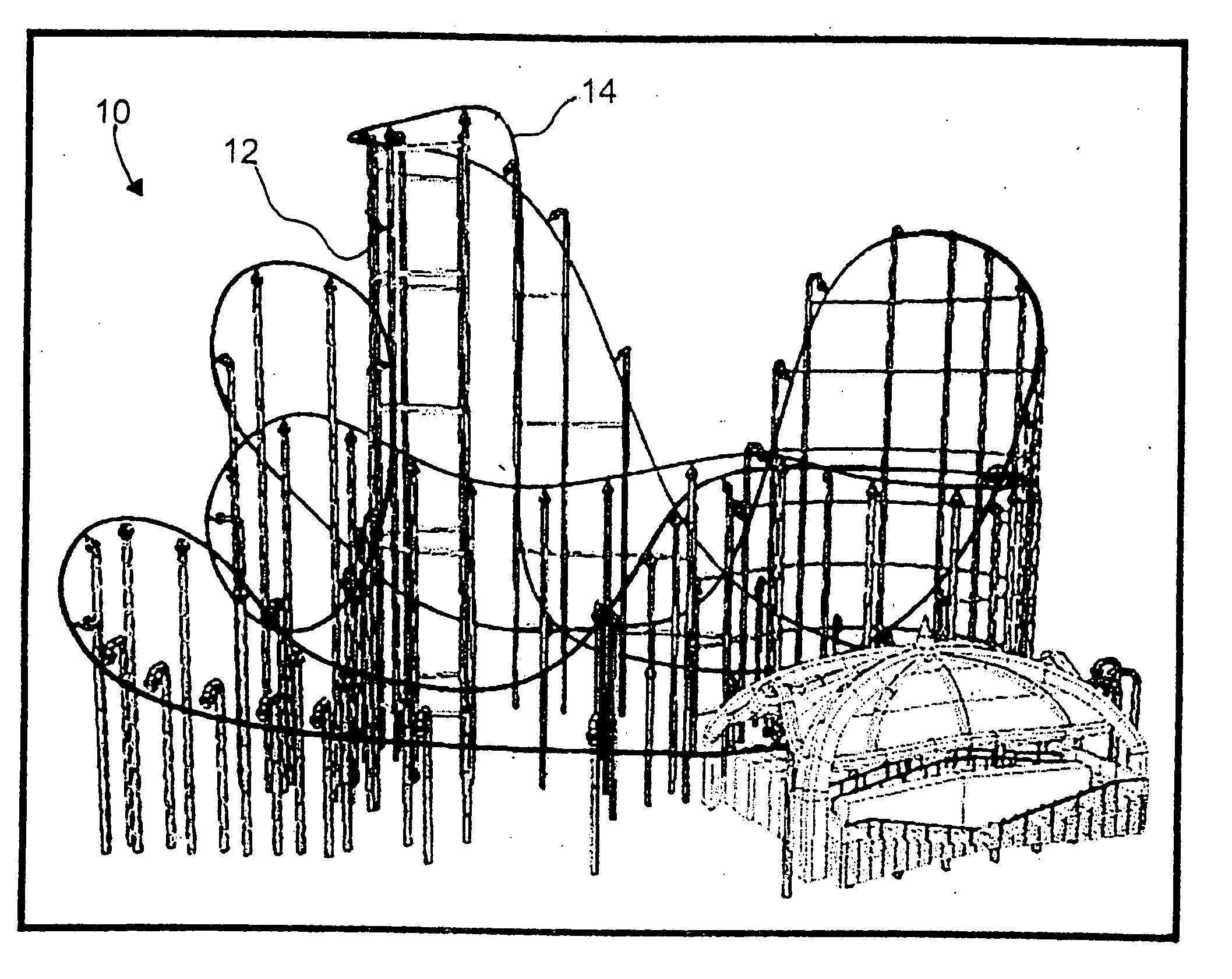

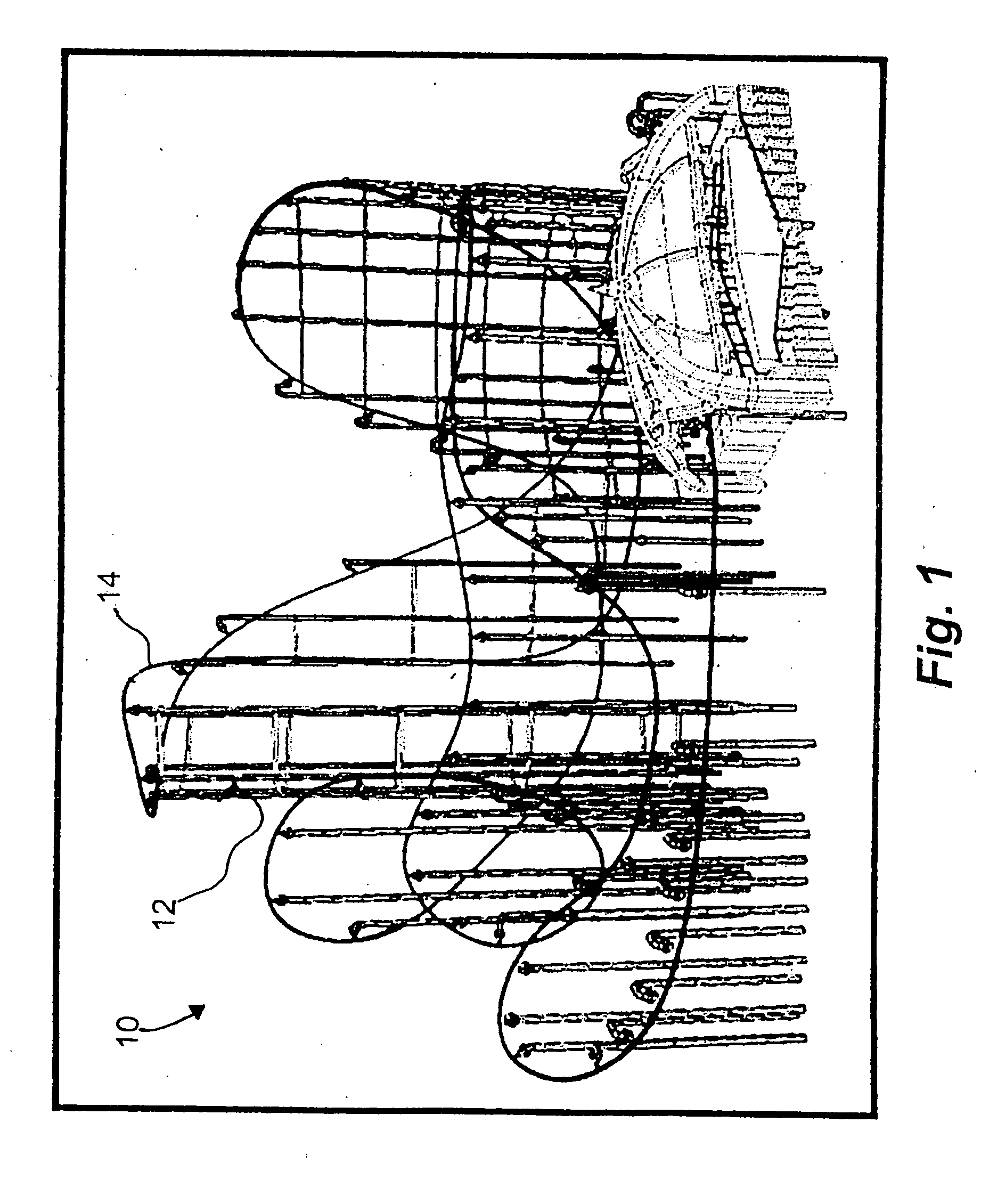

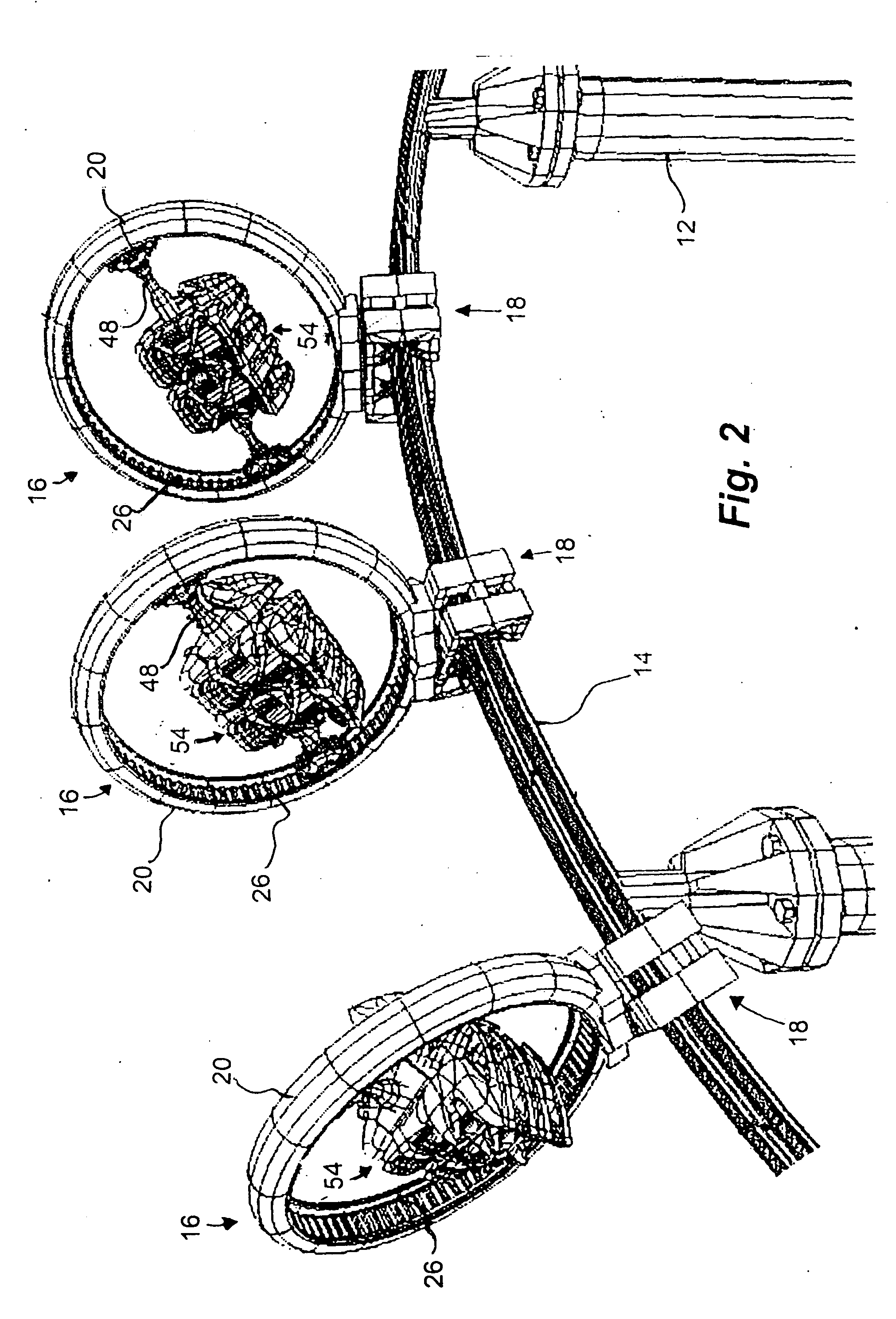

[0036] As illustrated in the accompanying drawings for purposes of illustration, the present invention resides in an amusement ride wherein one or more riders sit and are restrained into a seat of a vehicle assembly which travels along a track system of either a roller coaster or a vertical tower-type ride. The vehicle assemblies of the present invention are designed and configured such that the seats thereof rotate along at least two axes, and preferably three axes, independent of the track system. As will be more fully described herein, although such rotation can be dependent upon acceleration forces exerted on the seats and vehicle assembly, typically such rotation is controlled either by mechanical systems linked to the track, or more preferably through actuators on the vehicle assembly itself. The use of actuators, such as electric motors, hydraulic motors, or pneumatic systems, enable the degree of rotation to be controlled and the ride to be non-static such that either the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com