Layer cutting apparatus

a cutting device and sleeve technology, applied in the direction of metal working devices, baking articles cutting/slicing, manufacturing tools, etc., can solve the problems of large and cumbersome devices, high labor intensity, and extreme care of the above-mentioned devices, and achieve the effect of safe, effective and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

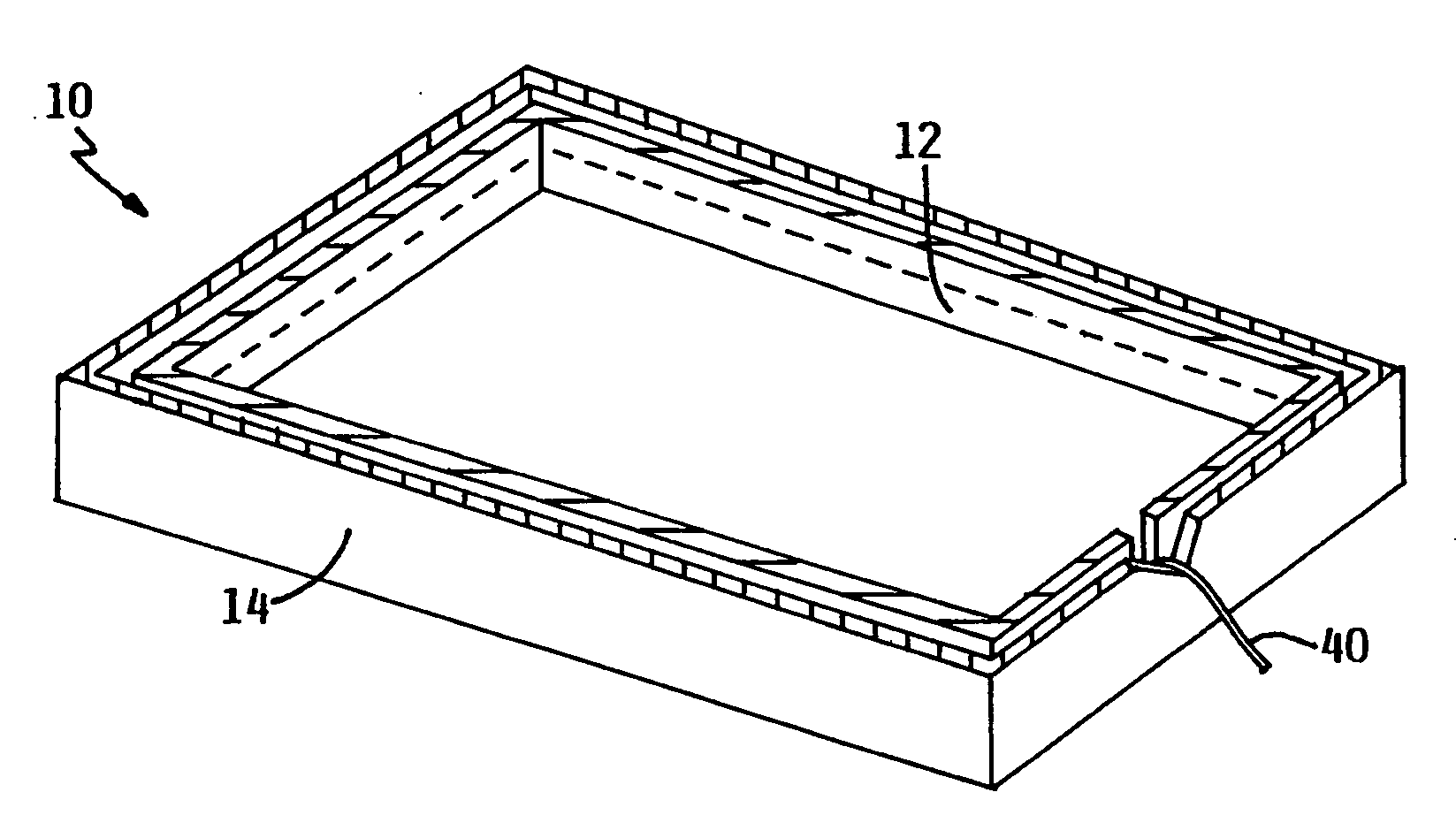

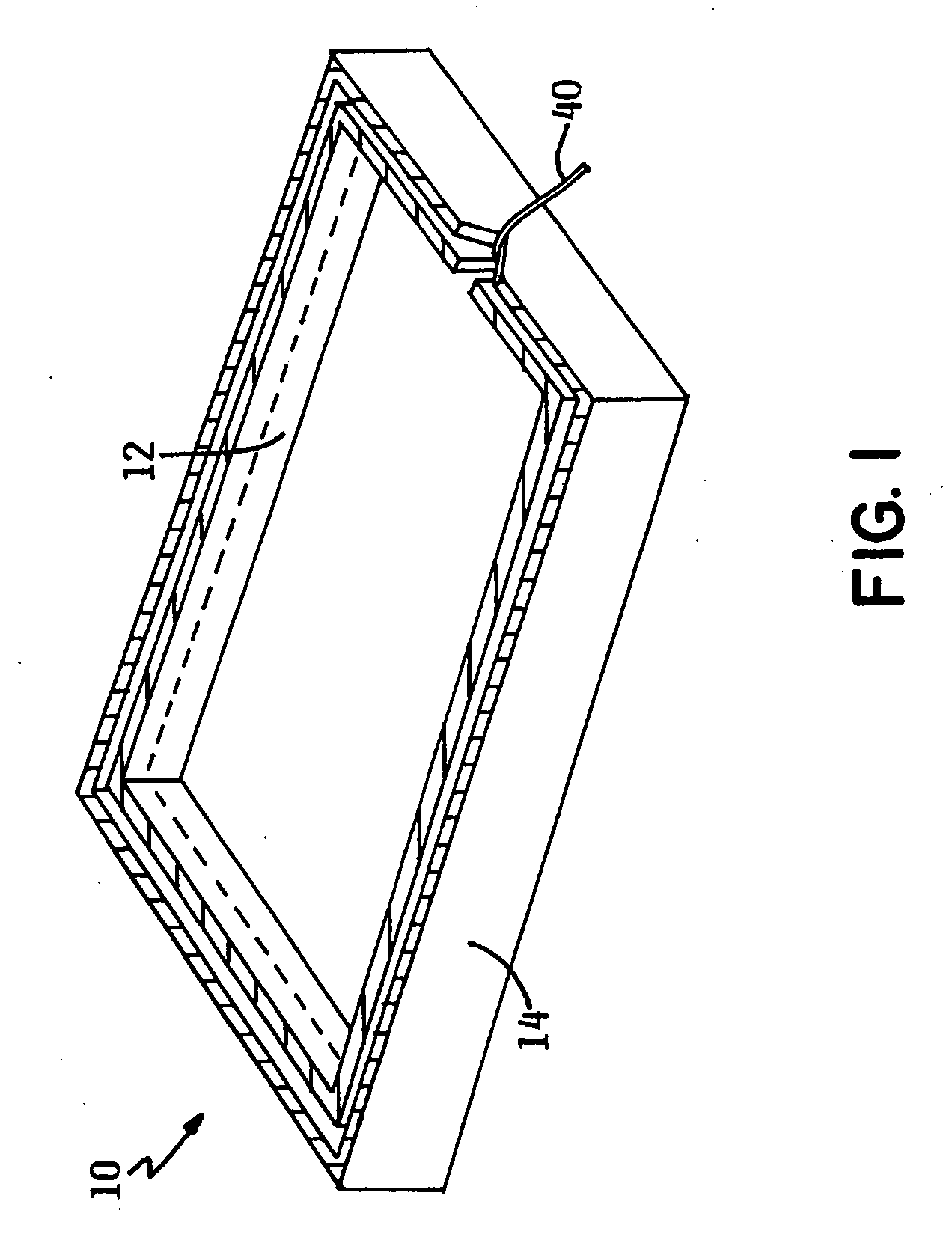

[0040] With reference to FIGS. 1 through 3, the cake-layer cutting apparatus 10 embodying the principles and concepts of the present invention will be described. Apparatus 10 includes sleeve 12 and tray 14. Sleeve 12 is configured to fit inside the inner periphery of tray 14 as shown.

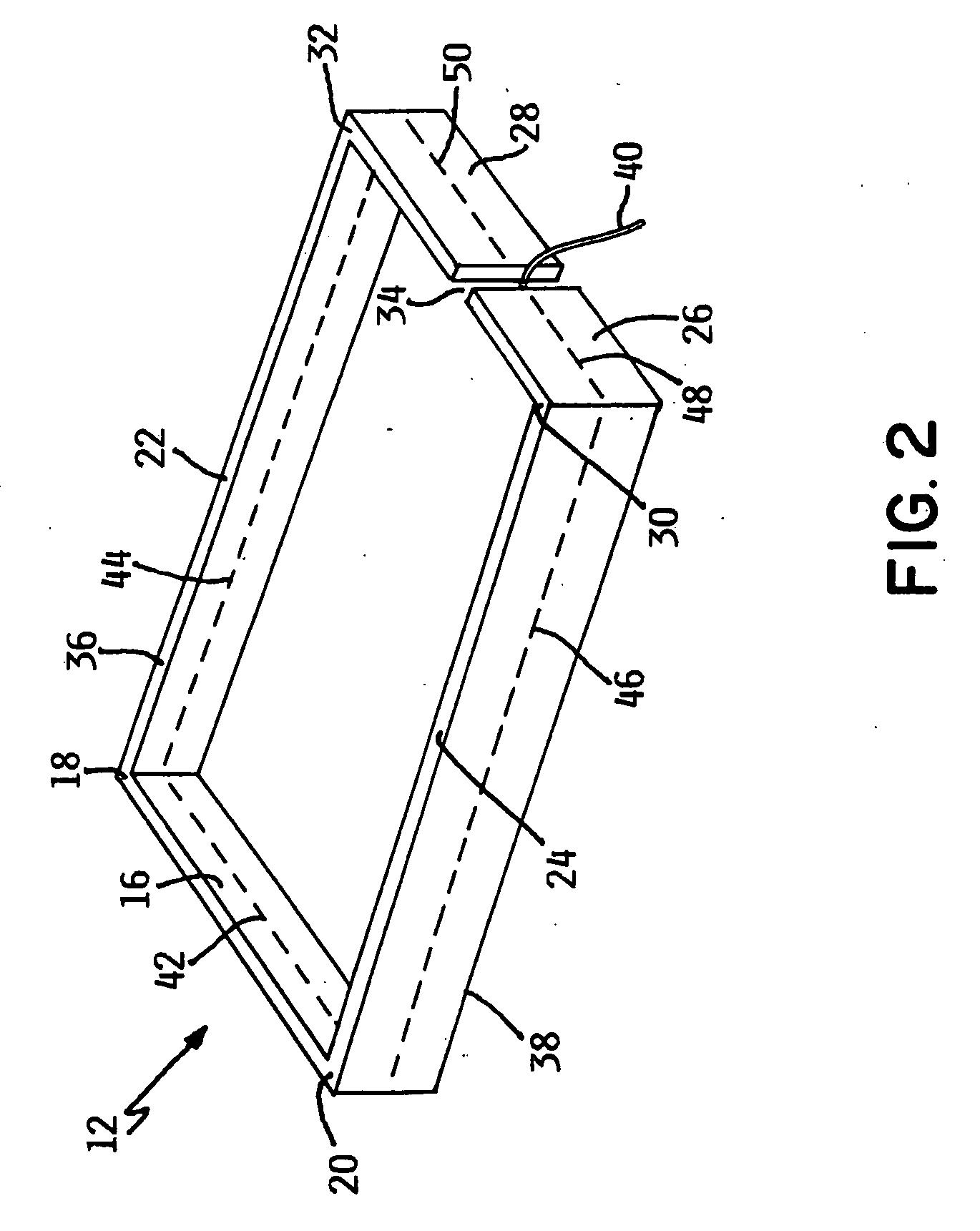

[0041] Sleeve 12 includes an elongated first side 16 terminating at a first corner 18 and a second corner 20. A second side 22 extends from first side 16 at first corner 18. Second side 22 terminates at third corner 32. Similarly, a third side 24 extends from first side 16 at second corner 20. Third side 24 terminates at fourth corner 30. Panel 26 extends from third side 24 at fourth corner 30. Panel 28 extends from second side 22 at third corner 32. Aperture 34 defines the area between panel 26 and panel 28.

[0042] Sleeve 12 includes a top edge 36 and a bottom edge 38. In FIG. 2, top edge 36 is shown parallel to bottom edge 38 although this configuration is not necessary to the invention. Cutting line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com