Seat load sensing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

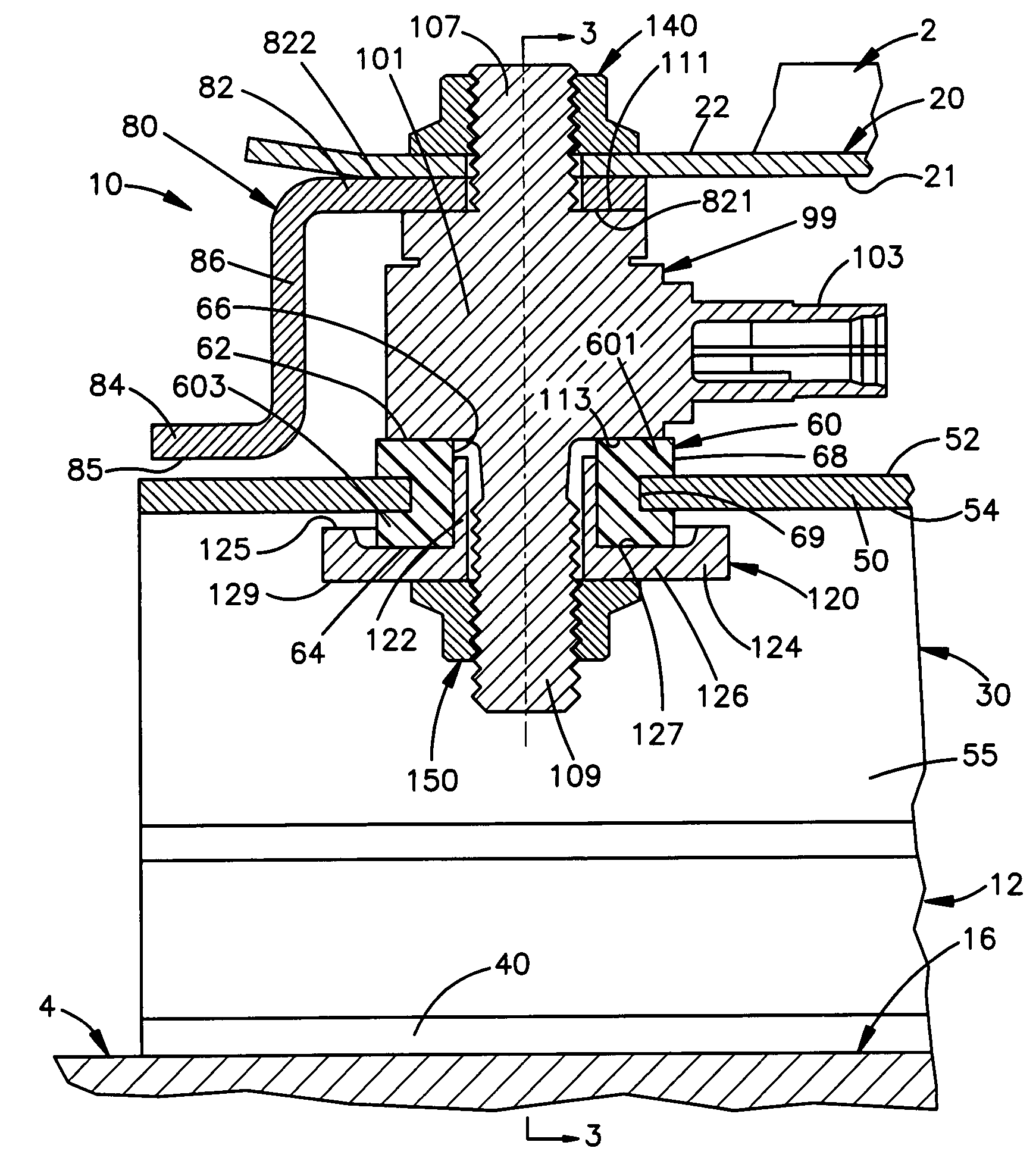

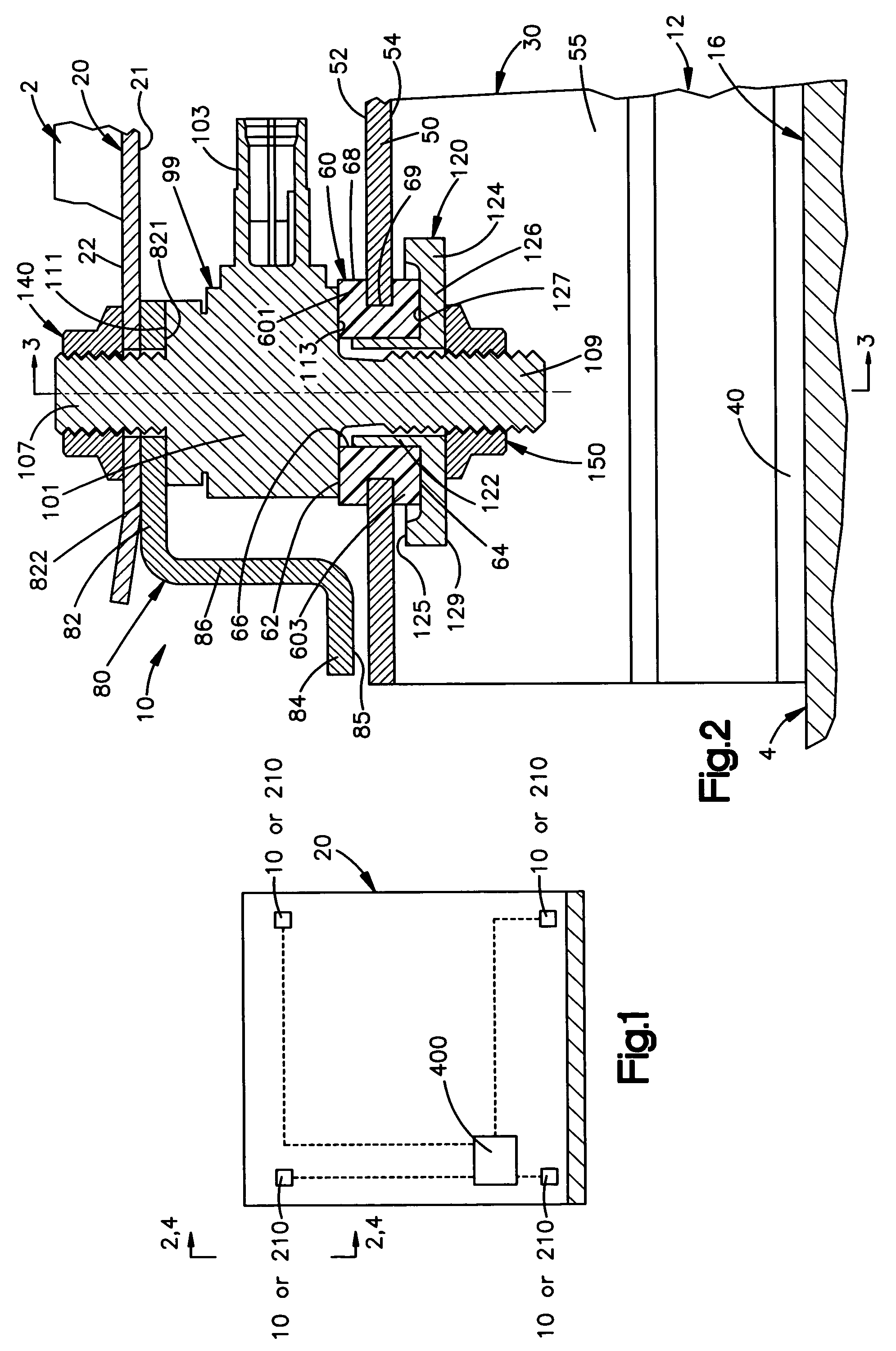

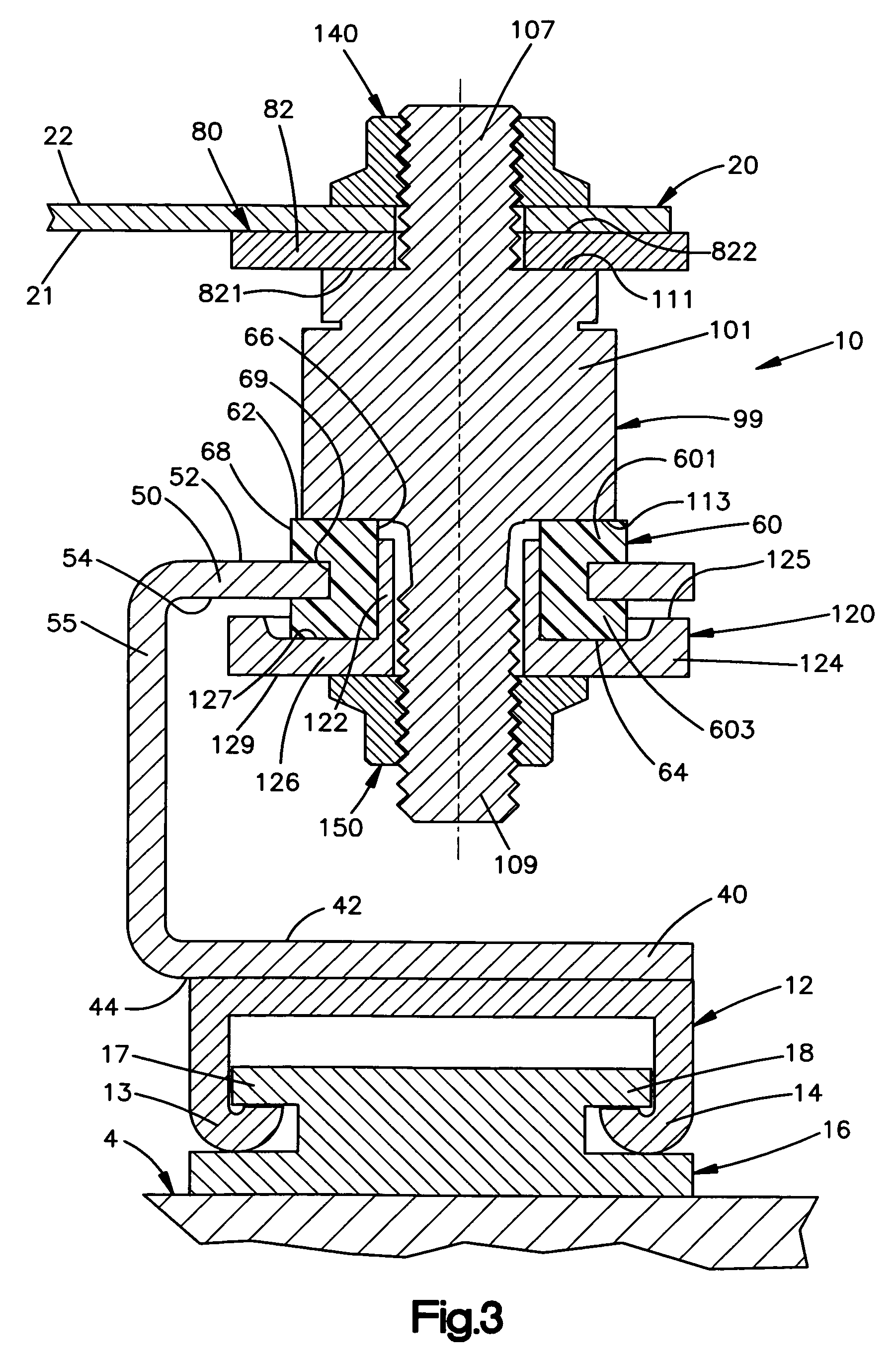

[0013] According to an aspect of the present invention, as shown in FIGS. 1-3, a vehicle occupant load sensing apparatus 10 is used in a vehicle having a seat 2 for the vehicle occupant. A vehicle floor pan 4 supports the vehicle seat 2. The apparatus 10 includes a vehicle seat frame 20 for supporting the vehicle seat 2, a sensor 99 for sensing a load placed on the vehicle seat, a resilient member 60 for absorbing dynamic loads imparted to the sensor by the vehicle seat, a bracket 30 for transmitting the load from the vehicle seat to the vehicle floor pan, an upper track 12 for supporting the bracket, and a lower track 16 for adjustably supporting the upper track.

[0014] The vehicle seat frame 20 supports a weight load of the vehicle occupant in the vehicle seat 2. During a vehicle collision, the seat frame 20 may also sustain upward and lateral loads created by the vehicle collision. The load of the vehicle occupant in the vehicle seat 2 is transmitted through the sensor 99, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com