Double air valve recoil dampener for firearms

a recoil dampener and double air valve technology, applied in weapon parts, butts, weapons, etc., can solve the problems of severe recoil that affects the person firing the weapon, the accuracy of the shooter, and the shooter raising the front of the firearm, so as to achieve the effect of absorbing the recoil, and reducing the cost of recoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

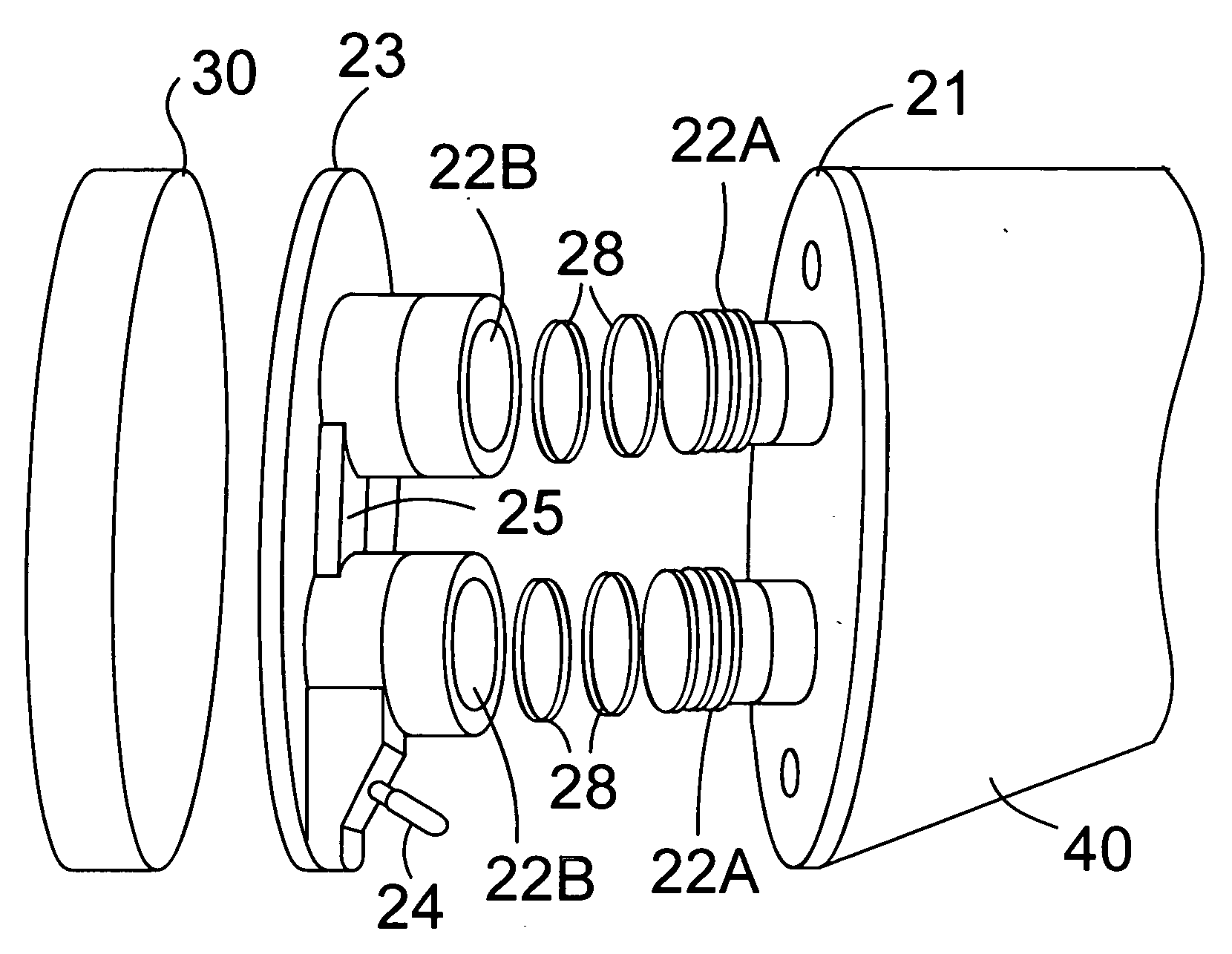

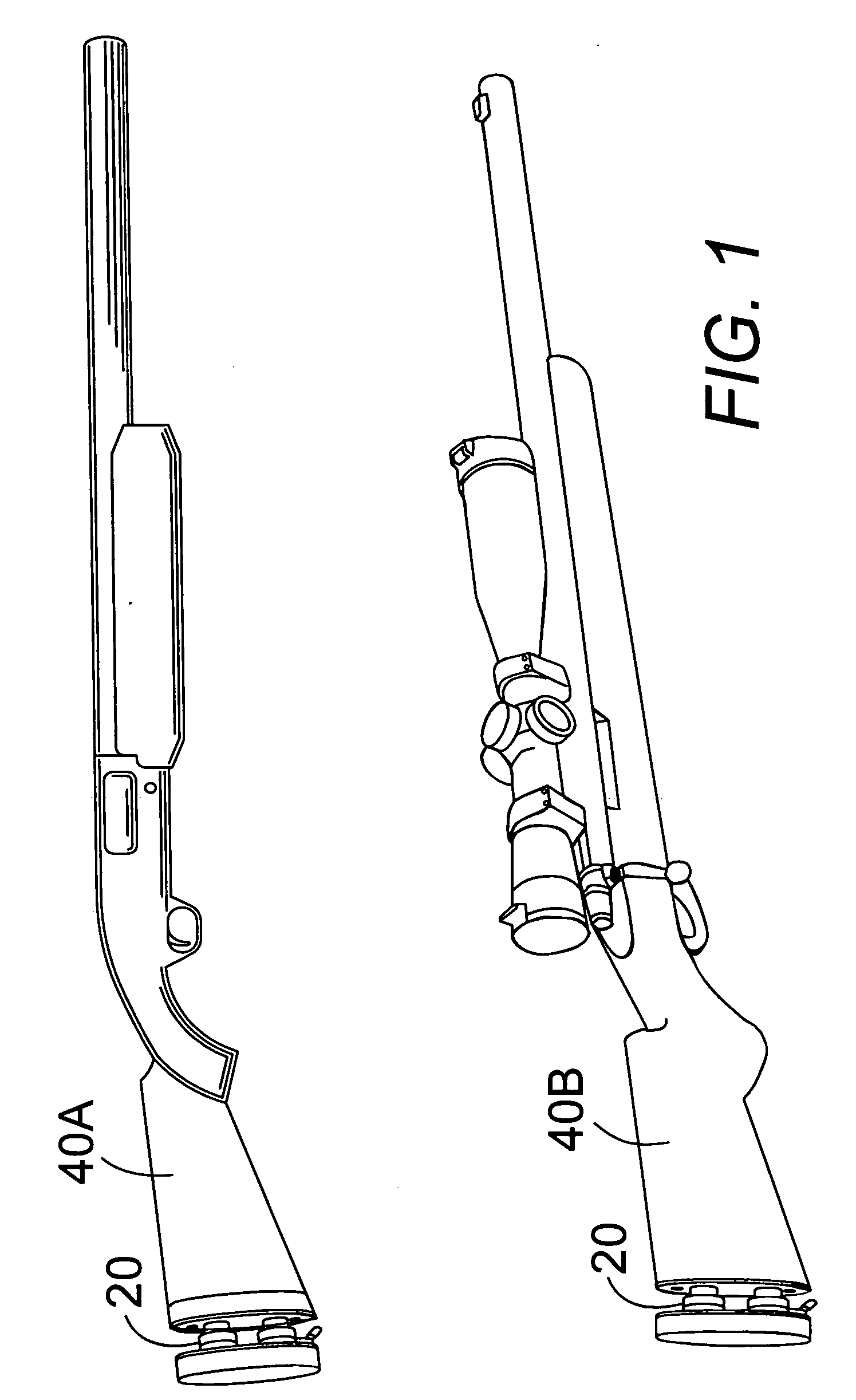

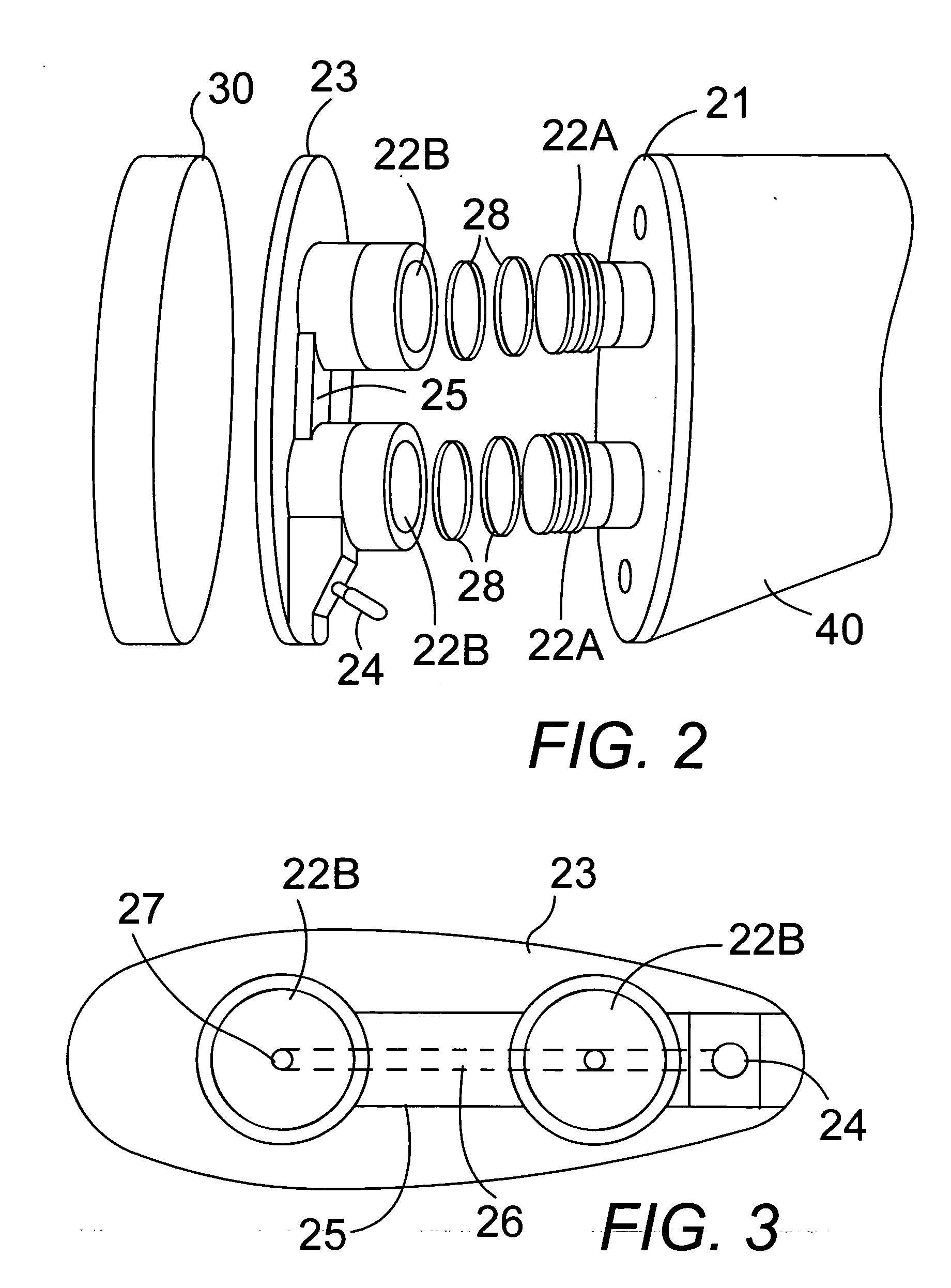

[0039] In FIGS. 1-4, a double air valve recoil damper device 20 for shotguns 40A and rifles 40B comprises a pair of pistons 22A mounted in a pair of cylinders 22B communicating with an air release outlet 26 and air release control valve 24.

[0040] The pair of pistons 22A are spaced apart and rigidly mounted on a butt end of a firearm 40 on a support cap 29 attached by a threaded end 14 screwed into threaded plate openings 15 in a plate 21 which screws onto an end of a rifle butt 40. The pair of pistons 22A each comprise a cylindrical shaft with preferably two circular grooves 18 around a perimeter of an end of the cylindrical shaft receive an O-ring 28 in each of the grooves.

[0041] A mating pair of cylinders 22B are mounted on a plate 23 attached to a shoulder pad 30 for the firearm. The pair of cylinders 22B are sized to receive the pair of pistons 22A with one of the pistons in each of the cylinders fitting with an air-tight slidable fit to compress the air in each cylinder. In F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com