Bath drain closure assembly

a technology for drain closures and bathtubs, applied in water installations, domestic plumbing, construction, etc., can solve the problems of overly expensive manufacture, installation, or repair, and other problems, and achieve the effect of reducing the number of problems, and avoiding the need for maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

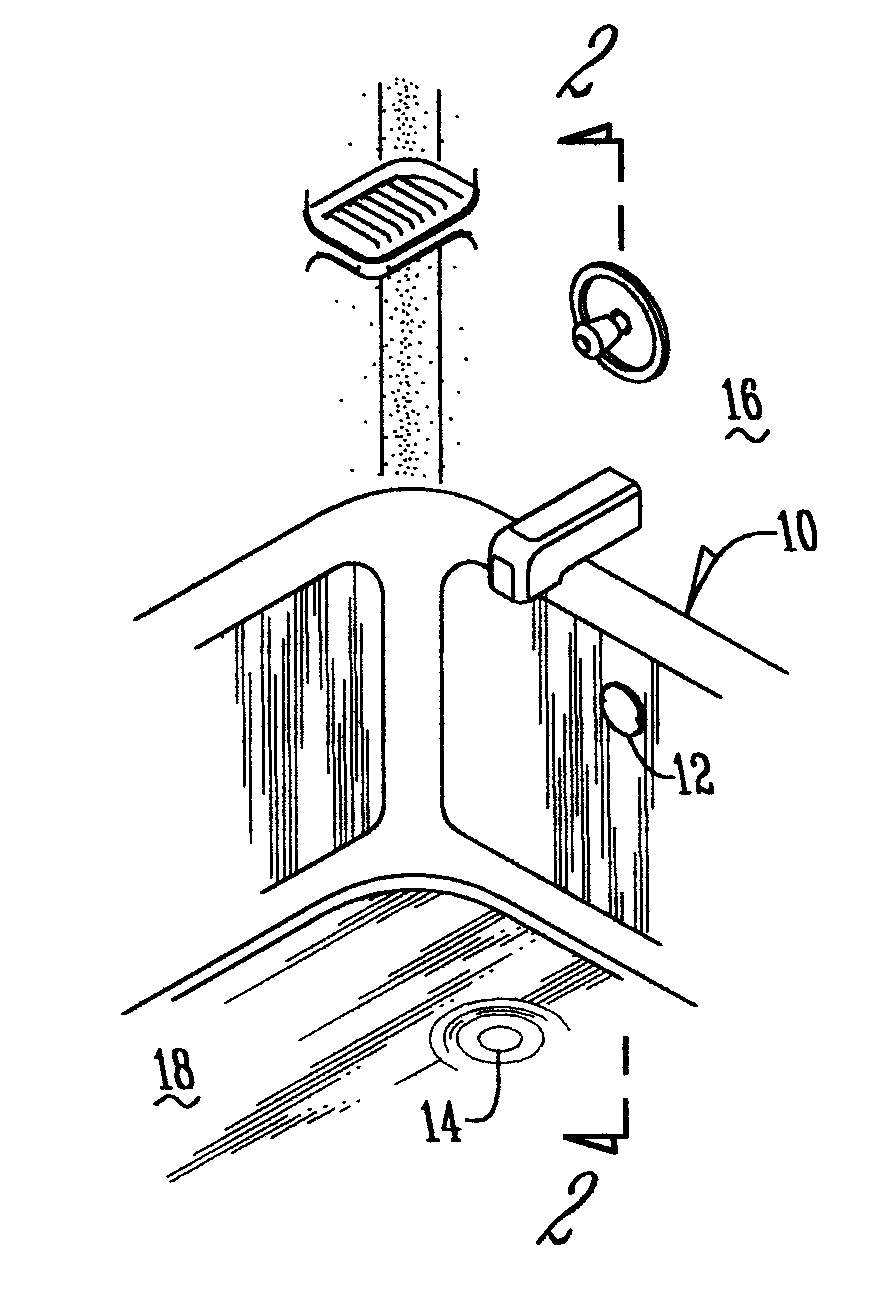

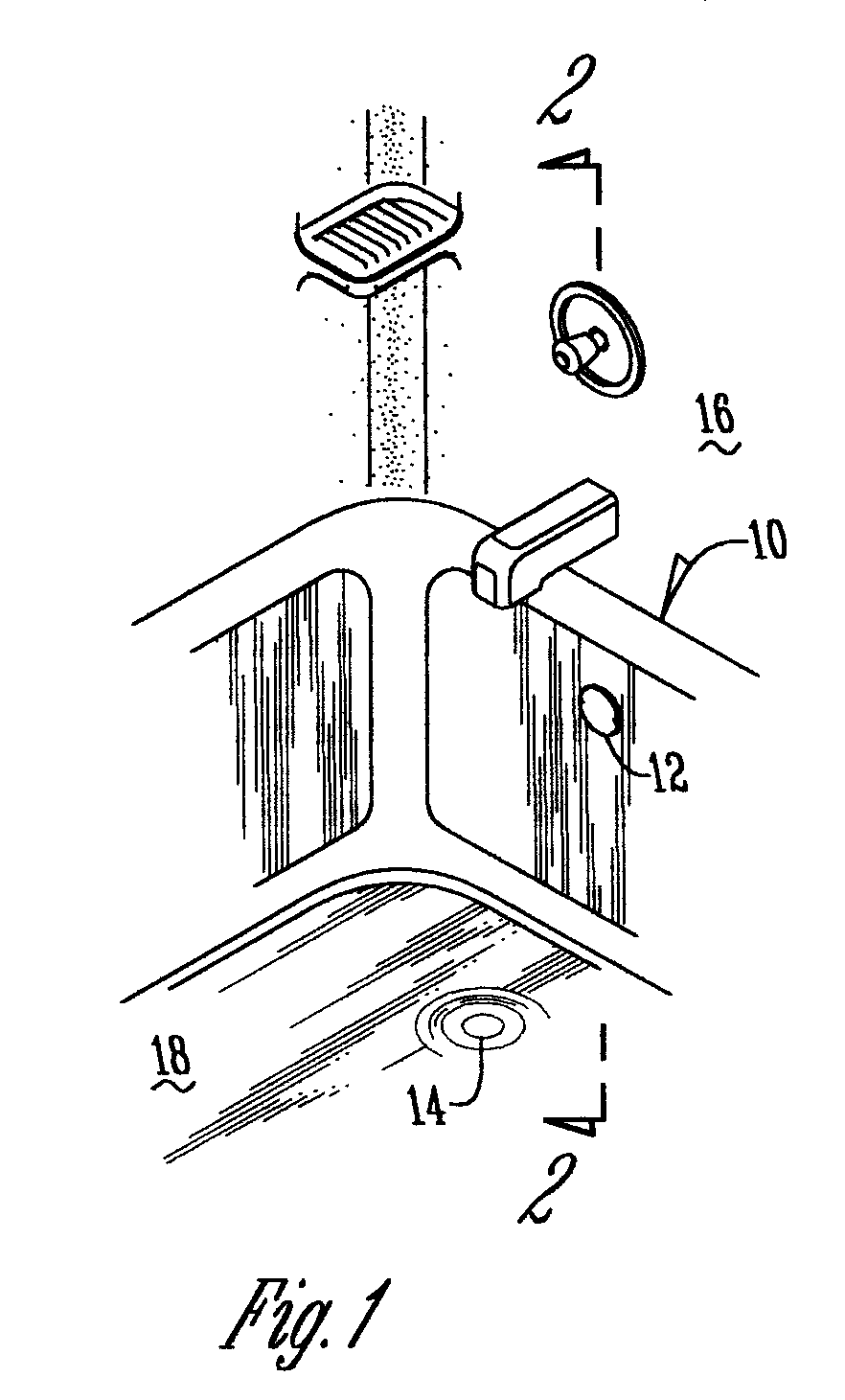

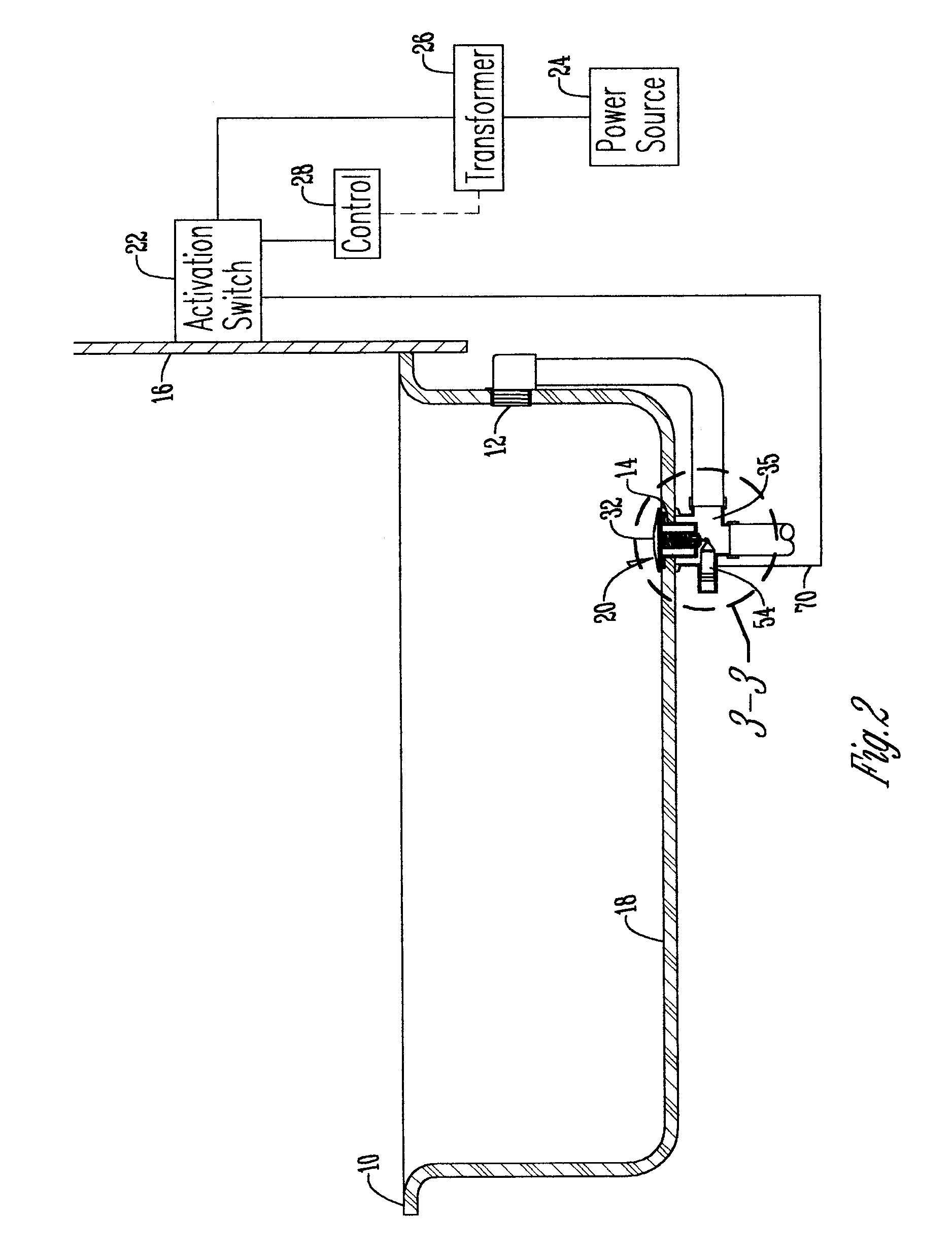

[0014] With reference to FIGS. 1 and 2, a conventional bathtub 10 has an upper overflow drain 12 and a lower drain 14. The upper overflow drain 12 is located at one end wall 16 of the bathtub 10 for draining overflow fluids from the bathtub 10. The lower drain 14 is located in the bottom 18 of the bathtub 10 for draining fluids from the bottom of the bathtub 10.

[0015] The bath drain closure assembly 20 is mated with the lower drain 14 to open and close the drain 14 to allow and prevent fluid flow. An activation switch 22 is preferably located in the end wall 16 of the bathtub 10 and is electronically connected to the drain closure assembly 20. Alternatively, the activation switch 22 is located on a far wall or deck of the tub. The activation switch 22 allows a user to selectively activate the drain closure assembly 20 to open and close drain 14.

[0016] A power source 24 is connected to the activation switch 22 to provide power to the drain closure assembly 20 through the activation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com