Putter head

a technology of putter head and putter head, which is applied in the field of putter head, can solve the problems of difficult to grasp the distance of the putt, dull hitting sound,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

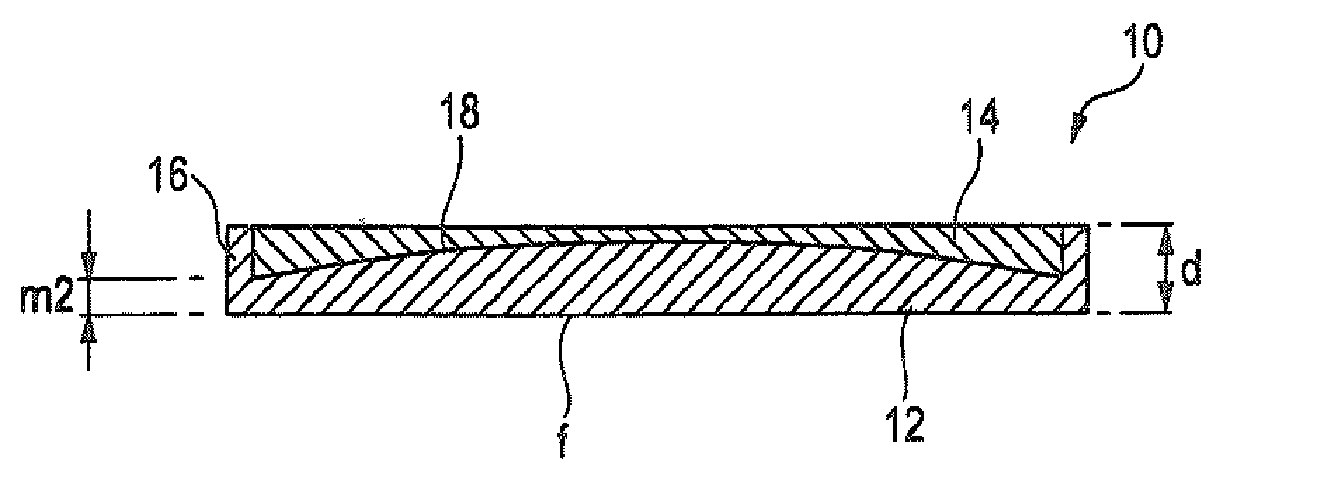

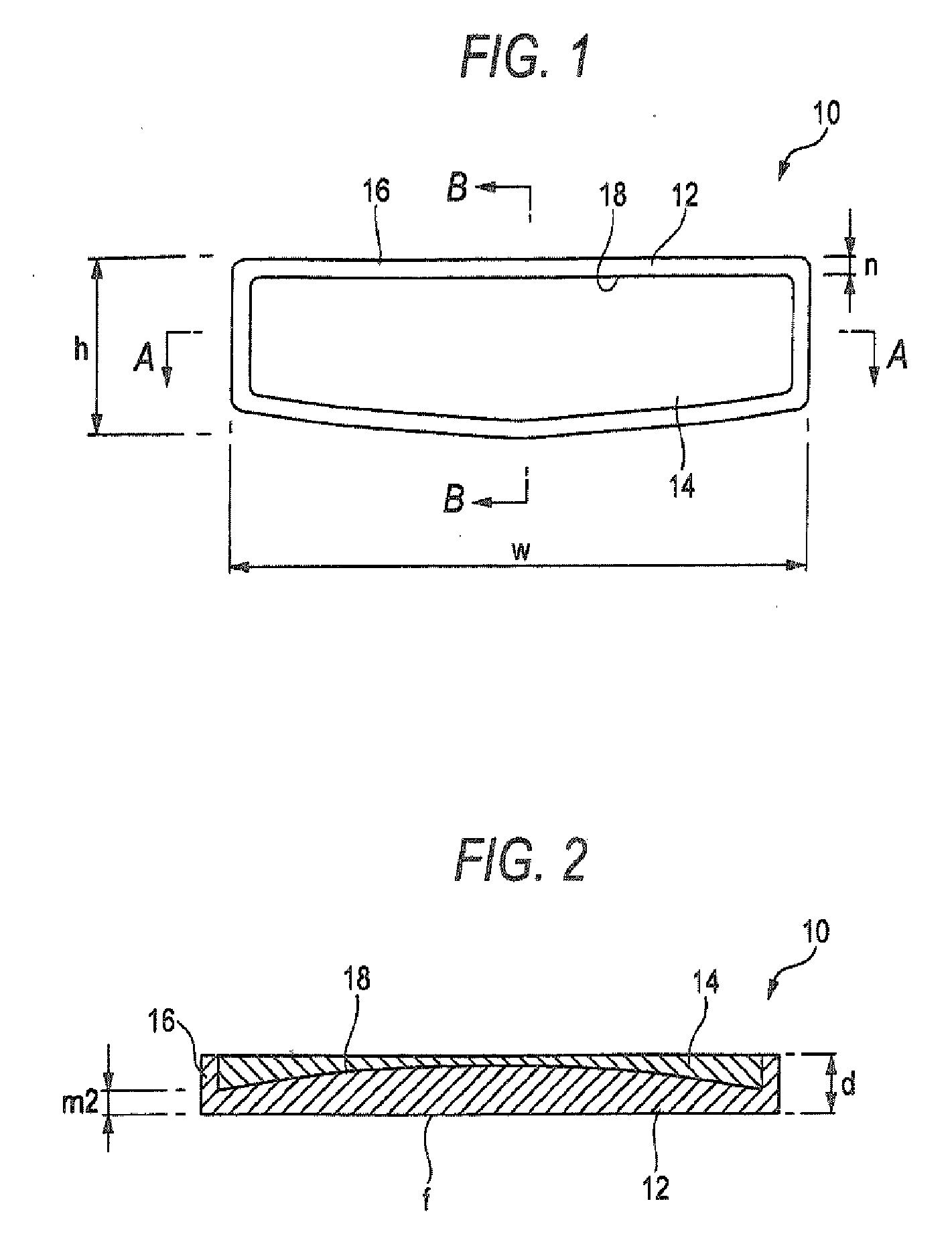

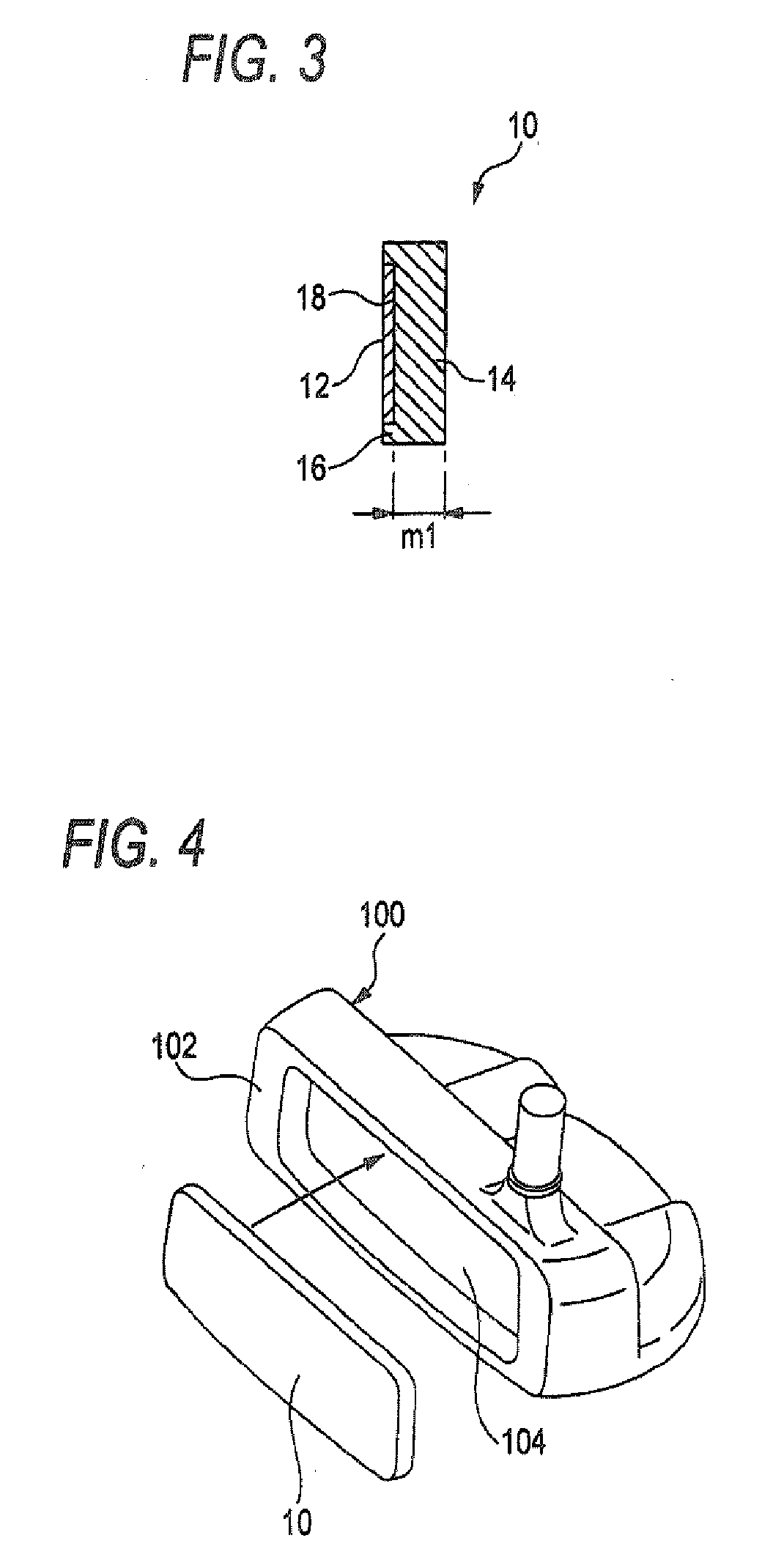

[0030]FIG. 1 is a rear view illustrating a face insert used in a putter head according to a first embodiment of the invention. FIG. 2 is a cross-sectional view taken along line A-A in FIG. 1. FIG. 3 is a cross-sectional view taken along line B-B in FIG. 1. A face insert l0 in accordance with this embodiment includes a high-hardness portion 12 that forms a hitting surface and a low-hardness portion 14 that is joined to an inner surface of the high-hardness portion l2. The hardness of the low-hardness portion 14 is lower than that of the high-hardness portion 12. In addition, in the face insert 10 of this embodiment, the thickness of the high-hardness portion 12 becomes gradually smaller from a central portion toward a peripheral portion in the longitudinal cross section shown in FIG. 2. It should be noted that the thickness of the high-hardness portion 12 is fixed in the transverse cross section shown in FIG. 3. Furthermore, in the face insert 10 of this embodiment,...

second embodiment

(Second Embodiment)

[0031]FIG. 5 is a rear view illustrating a face insert used in a putter head according to a second embodiment of the invention. FIG. 6 is a cross-sectional view taken along line A-A in FIG. 5. FIG. 7 is a cross-sectional view taken along line B-B in FIG. 5. A face insert 20 in accordance with this embodiment is similar to the first embodiment except that the frame-like body is not projectingly provided on the peripheral edges of the high-hardness portion 12. In FIGS. 5 to 7, the same component portions as those shown in FIGS. 1 to 3 are denoted by the same reference numerals, and a description thereof will be omitted. The use of the face insert 20 in accordance with this embodiment is similar to that of the first embodiment.

third embodiment

(Third Embodiment)

[0032]FIG. 8 is a longitudinal cross-sectional view illustrating a face insert used in a putter head according to a third embodiment of the invention. FIG. 9 is a transverse cross-sectional view taken along line B-B in FIG. 8. It should be noted that a rear view is the same as FIG. 1. A face insert 30 in accordance with this embodiment includes a high-hardness portion 32 that forms a hitting surface and a low-hardness portion 34 that is joined to the inner surface of the high-hardness portion 32. The hardness of the low-hardness portion 34 is lower than that of the high-hardness portion 32. In addition, in the face insert 30 of this embodiment, the thickness of the high-hardness portion 32 becomes gradually larger from the central portion toward the peripheral portion in the longitudinal cross section shown in FIG. 8. It should be noted that the thickness of the high-hardness portion 32 is fixed in the transverse cross section shown in FIG. 9. Furthermore, in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com