Enzymatic Treatment of Paper Making Pulps

a technology of paper making pulp and enzymes, applied in the field of papermaking pulp processing, can solve the problem that treatment can indeed take place, and achieve the effect of reducing the cationic demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Degradation of Pectin with Pectate Lyase and Pectinases

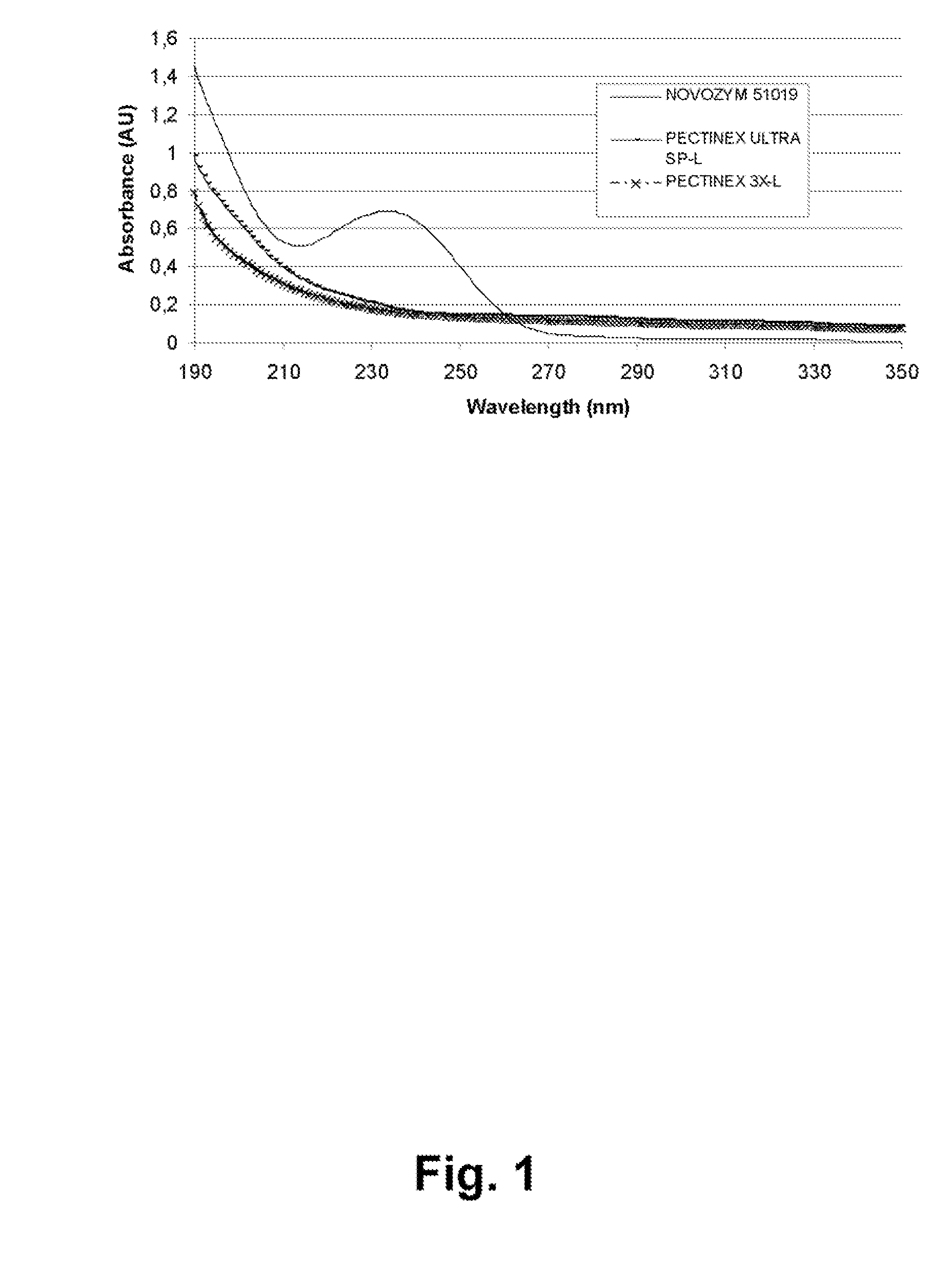

[0105] 1 g of polygalacturonic acid sodium salt (Sigma, P3850, minimum purity 85%) was dissolved in 1 L of de-ionized (DI) water. Aliquots of the solution were treated with NOVOZYM™ 51019 pectate lyase, and the pectinase preparations PECTINEX™ ULTRA SP-L, and PECTINEX™ 3X-L (all commercially available from Novozymes A / S, Krogshoejvej 36, DK-2880 Bagsvaerd, Denmark). The treatment took place for 60 min. at pH 7.0 and 55° C. Enzyme dosage was 40 mg / L of the three enzyme preparations, respectively. After the treatment, the solutions were acidified with 8% (w / w) phosphorous acid to pH 2.0. The solutions were diluted 10 times with DI water, and then the UV spectrum was determined by a UV-Vis spectrometer.

[0106] As shown in FIG. 1, the pectate lyase treatment leads to different degradation products as compared to the two pectinases, as evidenced by the characteristic strong UV absorbance at 235 nm. Pectinases degrade pectin into gal...

example 2

Effect of Pectate Lyase on Cationic Demand after Alkaline Treatment

[0107] A thermo-mechanical pulp (TMP) sample was treated with 2% NaOH at 6000 for 1 h. The treated pulp was then filtered through a Brit Jar (200 mesh screen) and the filtrate was neutralized to pH 7 by 0.1 N H2SO4. The filtrate was treated with different dosages of the NOVOZYM™ 51019 pectate lyase at 55° C. for 2 hrs.

[0108] Cationic demand was determined on all samples using a Mütek particle charge detector and an auto-titrator. 1.0 ml of sample was diluted in 20 ml of DI water and the suspension was titrated with 0.001 N of the cationic retention aid polydiallyldimethylammonium chloride (poly-DADMAC, commercially available from Aldrich).

TABLE 1Effect of Pectate Lyase on CationicDemand after Alkaline TreatmentNOVOZYM ™ 51019Cationic Demand,Pectate Lyasemeq / LSTD% Decrease 0 mg (control)0.6530.0340.0 4 mg / l0.5410.03117.220 mg / l0.4280.00834.540 mg / l0.4400.02332.8

example 3

Enzyme Treatment before Alkaline Treatment—Effect on Cationic Demand

[0109] A thermo-mechanical pulp (TMP) sample was treated with different dosages of the NOVOZYM™ 51019 pectate lyase, combinations thereof with NOVOSHAPE™ pectinesterase, and with the pectinase preparation PECTINEX™ ULTRA SP-L (all commercially available from Novozymes A / S, Krogshoejvej 36, DK-2880 Bagsvaerd, Denmark). The pulp suspension was adjusted to pH 7.0 before the enzyme treatment. The other enzyme treatment conditions were: 55° C., 4% consistency, for 2 hrs. Then, the pulp samples were further treated with 2% NaOH at 60° C. for 1 h. The treated pulp was then filtered through a Brit Jar (200 mesh screen) and the filtrate was neutralized to pH 7 by 0.1 N H2SO4

[0110] Cationic demand was determined on alt samples using a Mütek particle charge detector and an auto-titrator. 1.0 ml of sample was diluted in 20 ml of DI water and the suspension was titrated with 0.001 N of the cationic retention aid polydiallyldim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com