Bottom weight device of a roller blind

a bottom weight and roller blind technology, applied in the direction of snap fasteners, door/window protective devices, buckles, etc., can solve the problems of not being perfect at all, achieve superior bottom weight effect, move more smoothly, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

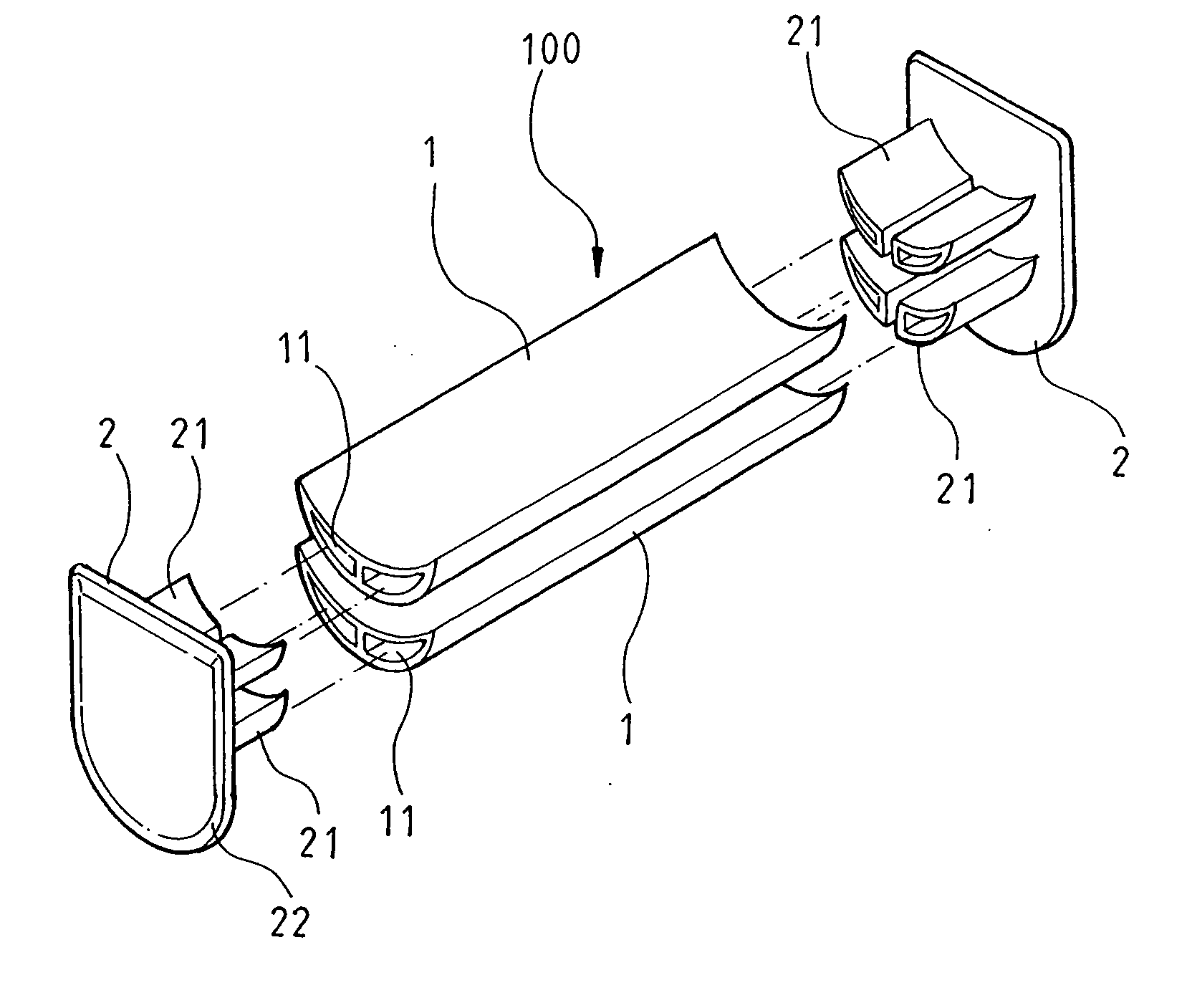

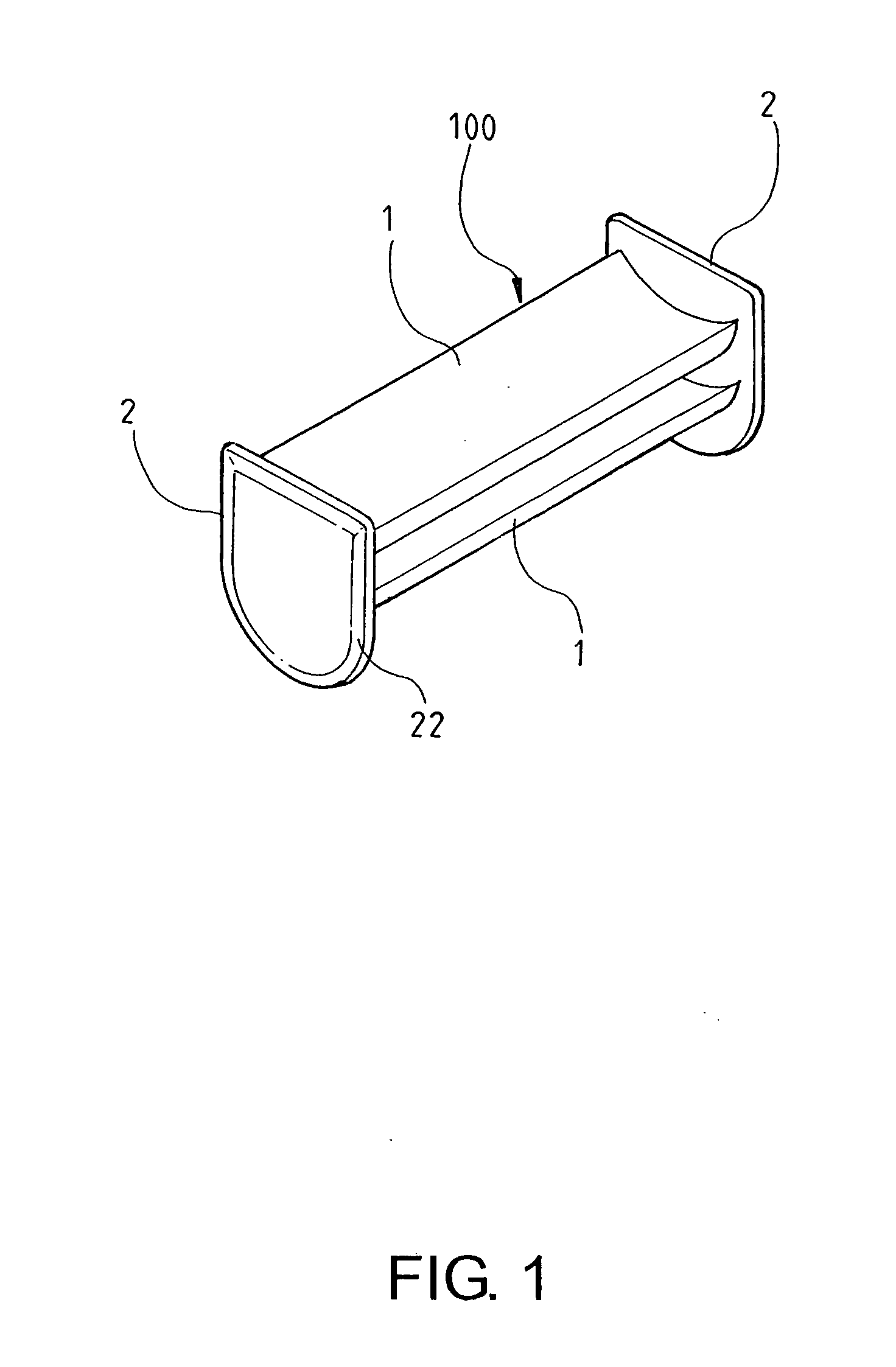

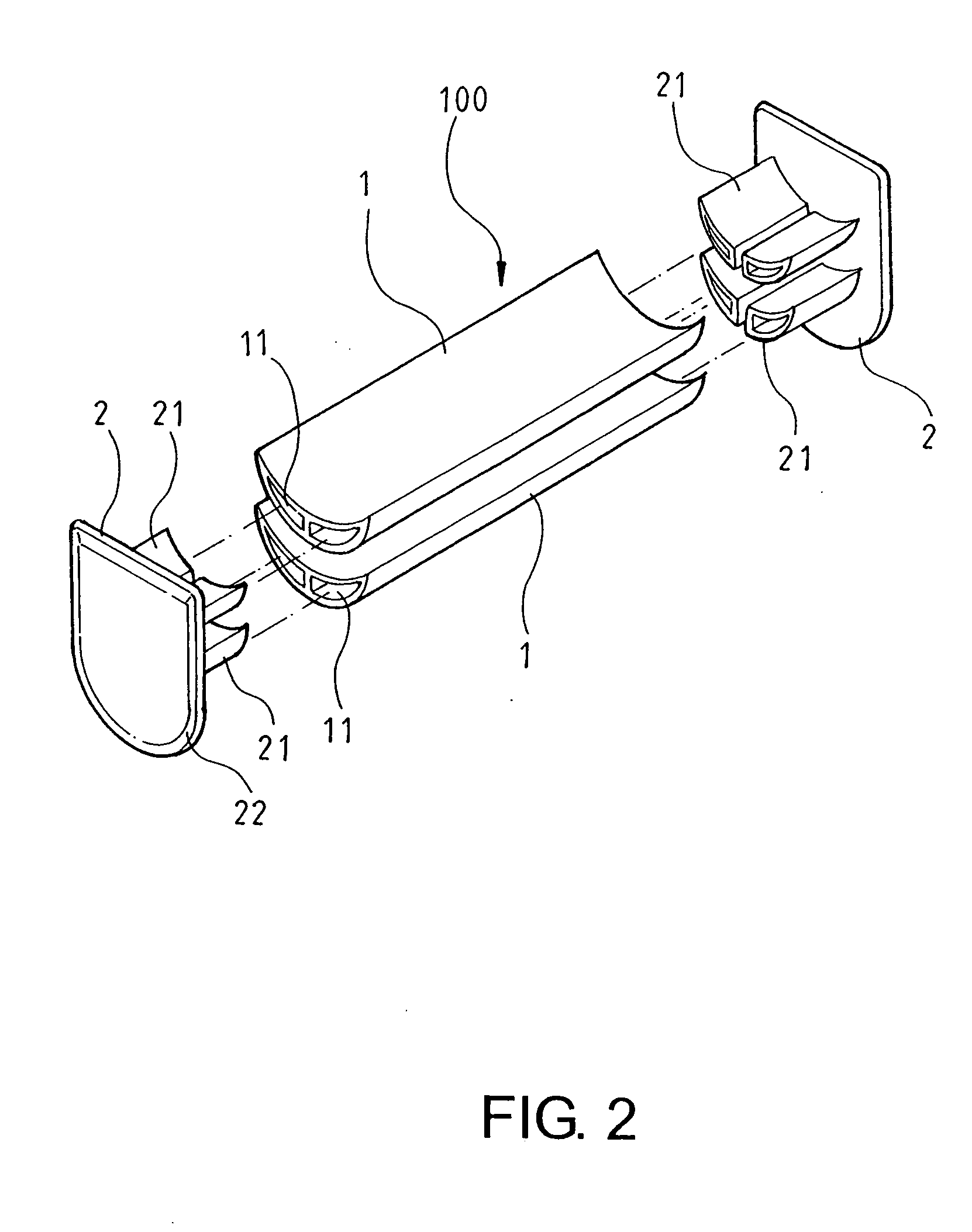

[0013] Referring to FIG. 1 and FIG. 2, the present invention comprises primarily two rails 1 and two side covers 2, wherein the two rails 1 are roughly in a U-shape, bottom rims of which are formed with an arc, and which are provided with symmetric longitudinal boreholes 11. Inner rims of the two side covers 2 are provided with lock lumps 21 corresponding to the boreholes 11 of rails 1, the lock lumps 21 are separated by a proper distance, and peripheries of the two side covers are inclined by about 10 degrees.

[0014] Through an assembly of the aforementioned structures, the two side covers 2 are fixed at two sides of rails 1 by latching the lock lumps 21 to the boreholes 11 of rails 1, respectively, so as to constitute a bottom weight device 100, which enables a bottom end of the roller blind to reeve around the gap between the two rails 1. Through a weight of the bottom weight device 100 and the arc of rail 1, the roller blind can move up and down more smoothly, and can be prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com