Synthetic cork with a natural cork appearance and method of making it

a cork and natural technology, applied in the field of container closures, can solve the problems of slow penetration of synthetic stoppers into the food and wine container industry, spoilage of products within containers, and unfit consumption of products, so as to achieve accurate simulation of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Methods of creating the random and irregular markings of the present invention include molding the details directly into the surface of the stopper and extruding the synthetic material into a desired shape before passing it through forming cylinders or rollers that contain the negative of the desired surface texture, and which imprint the texture onto the material's exterior surface.

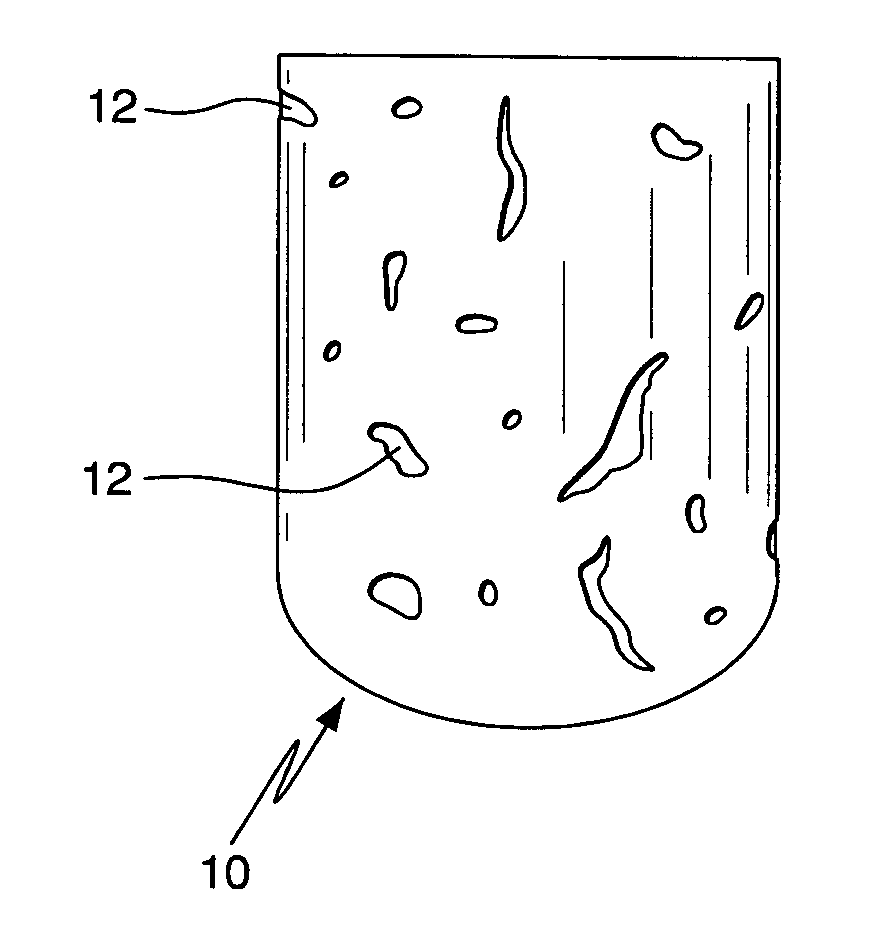

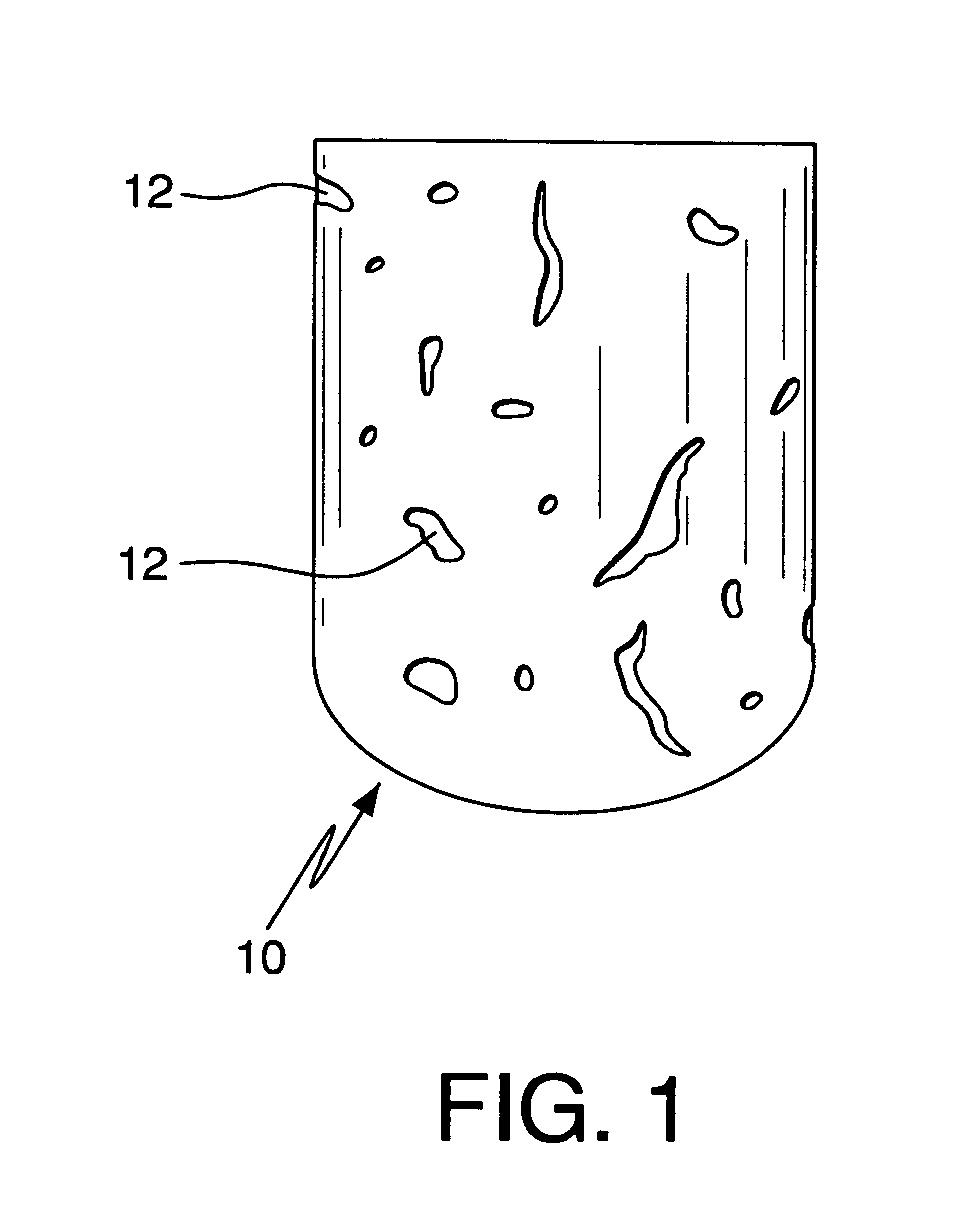

[0014]FIG. 1 shows a side elevation view of a stopper 10 made by a method in accordance with an exemplary embodiment of the present invention. Stopper 10 features random and irregular holes, markings, and dimples 12 on its outer surface. It will be obvious to one of ordinary skill in the art that the exact outer shape of stopper 10 is not limited to the shape depicted in FIG. 1; a number of methods of shaping a stopper are well-known in the art. Accordingly, the shape depicted in FIG. 1 should not be construed as limiting the present invention.

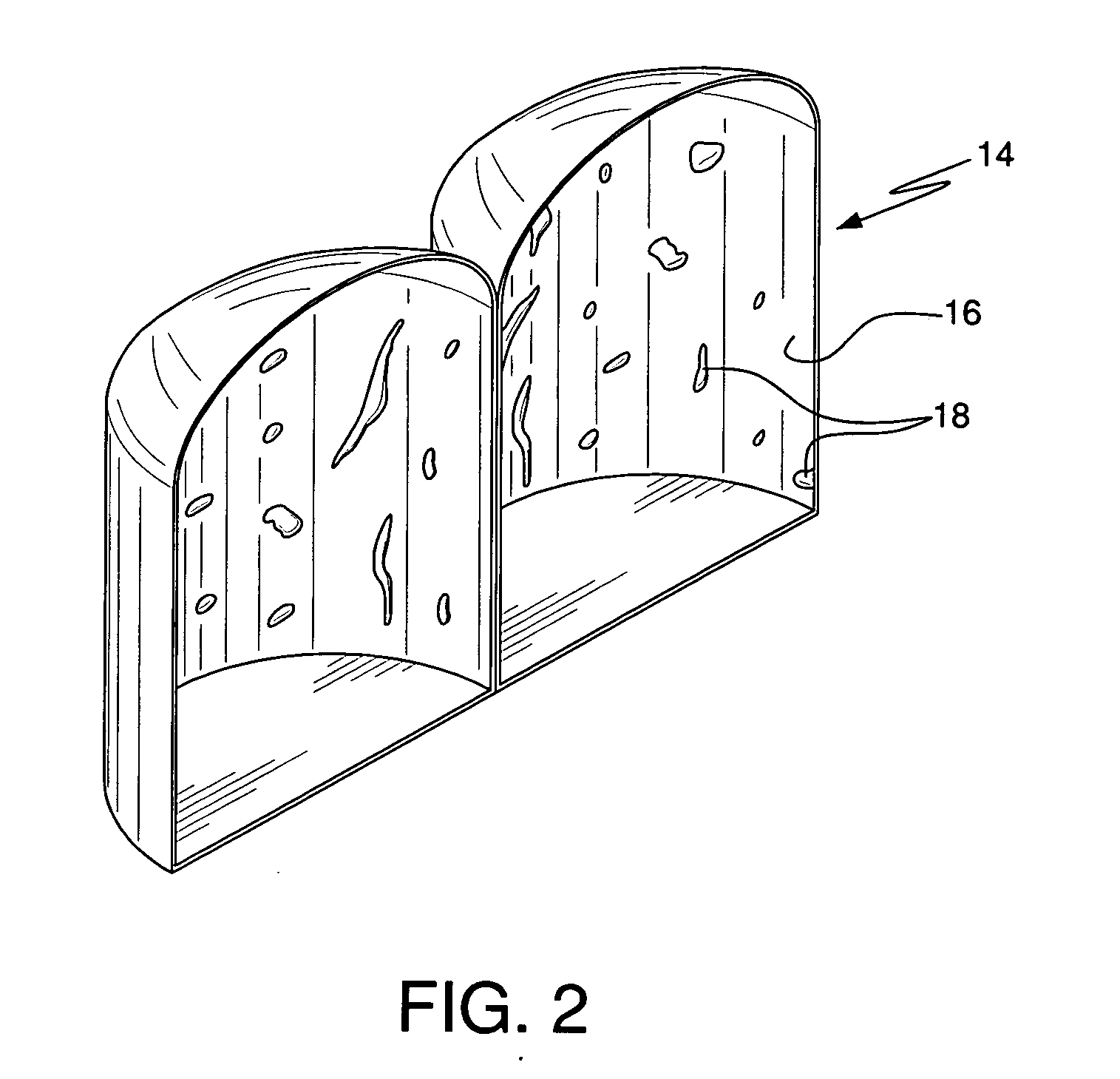

[0015]FIG. 2 shows a mold 14 used in a method in acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com