Peg board

a peg board and peg technology, applied in the field of peg boards, can solve the problems of increasing shipping costs, increasing installation difficulty, and affecting the installation efficiency of peg boards, and achieve the effect of reducing disadvantages and problems and reducing the disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A need therefore exists for peg board that eliminates or diminishes the disadvantages and problems described above.

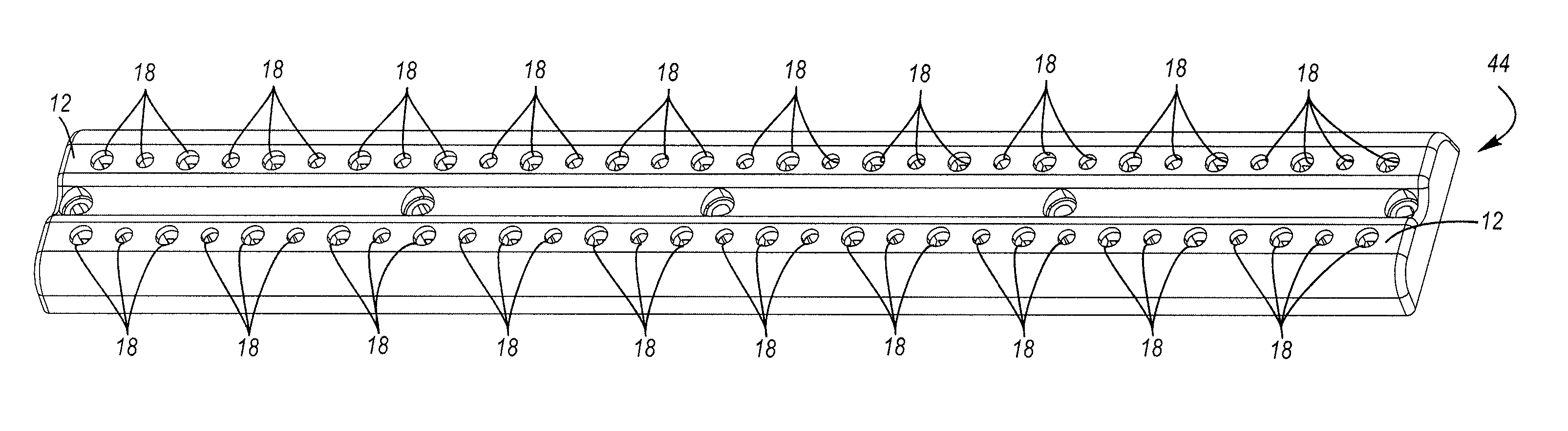

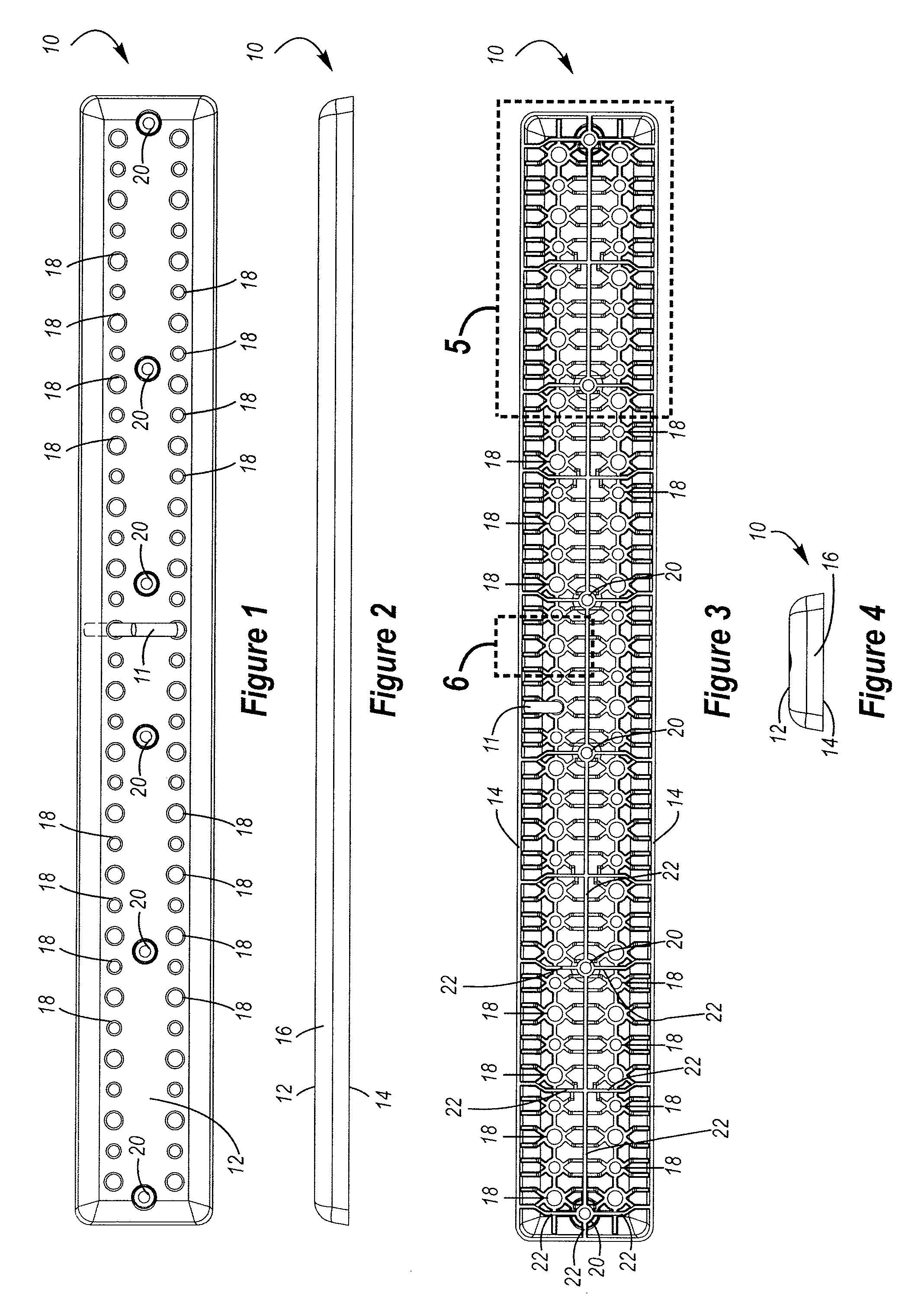

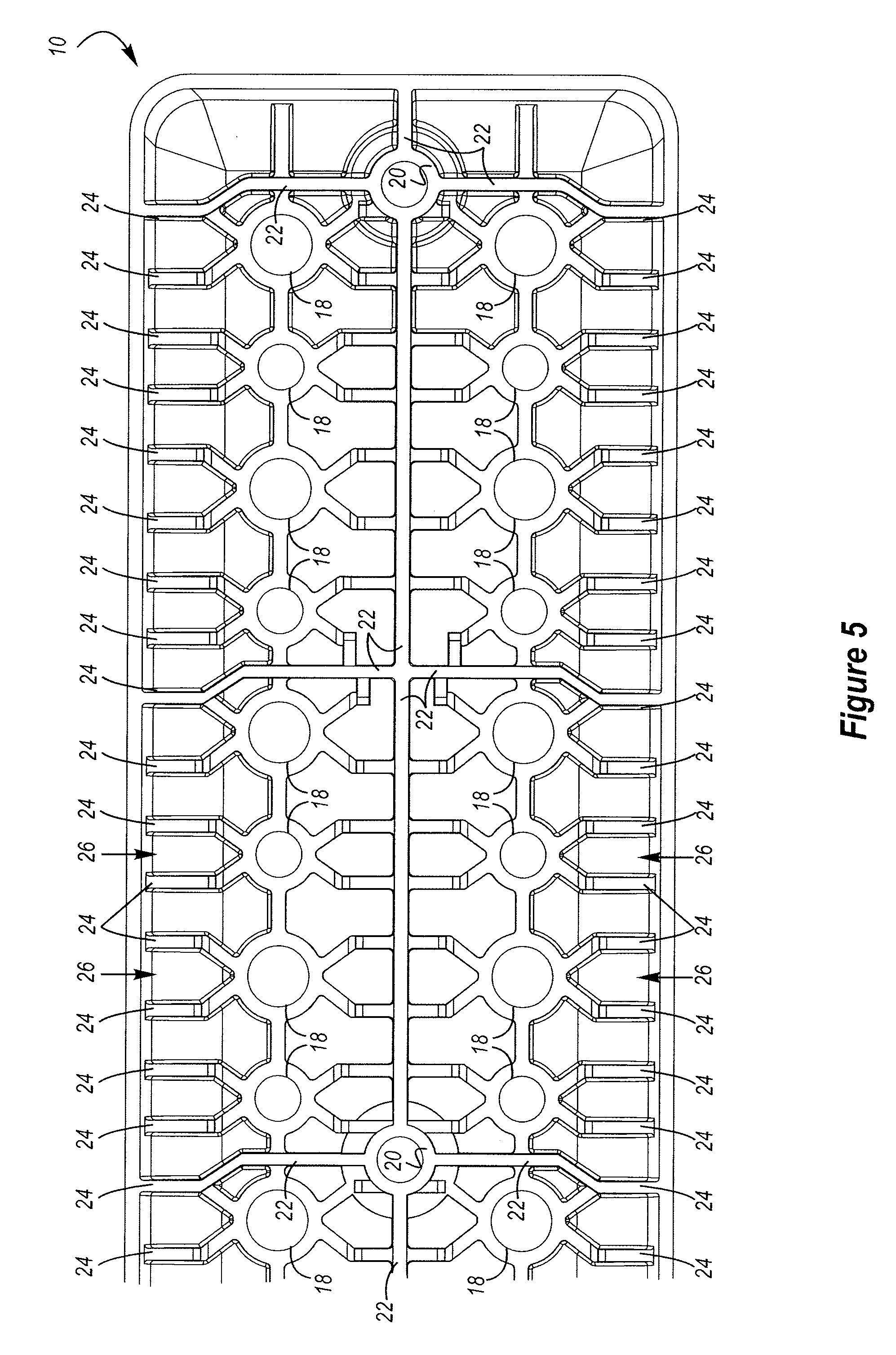

[0017] One aspect of the invention is peg board that may be used to store and / or organize various items. For example, various types of hooks, supports, braces, brackets, racks and the like may be attached to the peg board, and these structures may be used to hold and / or position various items in desired locations. Advantageously, these structures may be selectively attached and / or removed from the peg board.

[0018] Another aspect is peg board that may include openings having a first size and a second size. In particular, the peg board preferably includes both larger-sized holes with a diameter of about 5 / 16 of an inch and smaller-sized holes with a diameter of about 3 / 16 of an inch. Preferably the holes alternate between the larger and smaller sizes. Advantageously, this may allow larger-sized and smaller-sized hooks, with diameters of ¼ inch and ⅛ inch respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com