Stacking containers

a technology for stacking containers and containers, applied in the field of stacking containers, can solve the problems of inability to align containers in a point of purchase display, stacking containers can collapse, etc., and achieve the effect of limiting relative horizontal movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

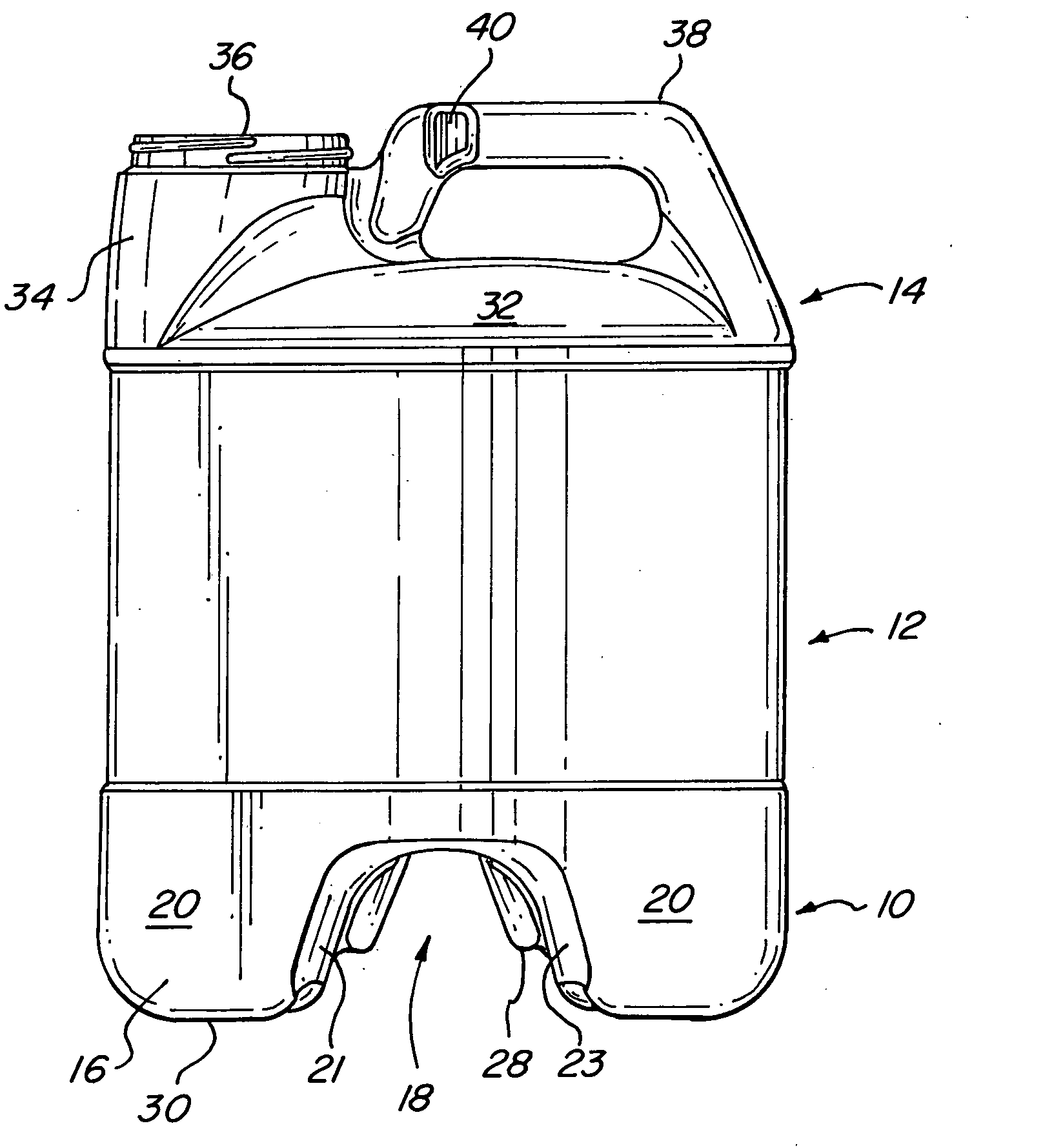

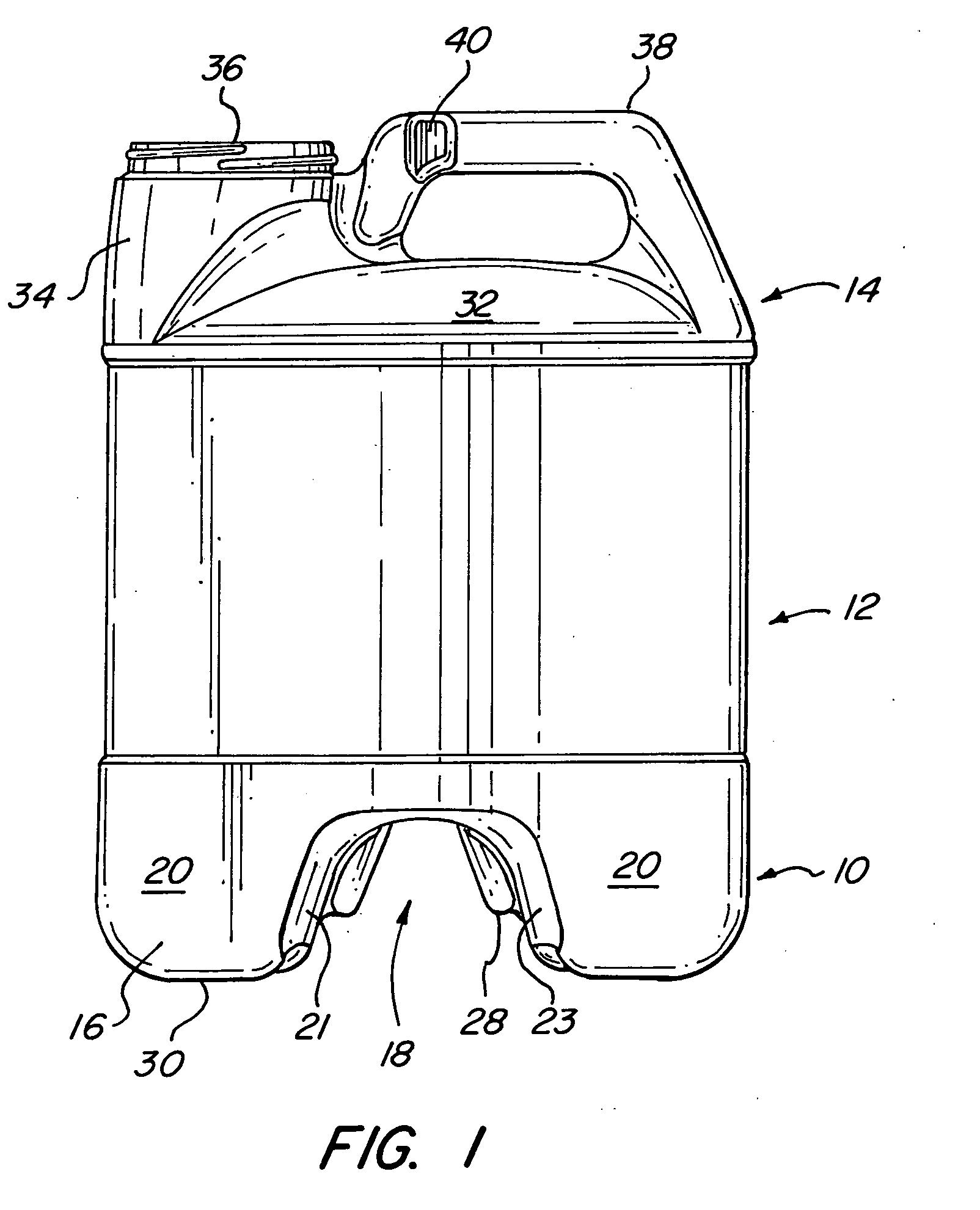

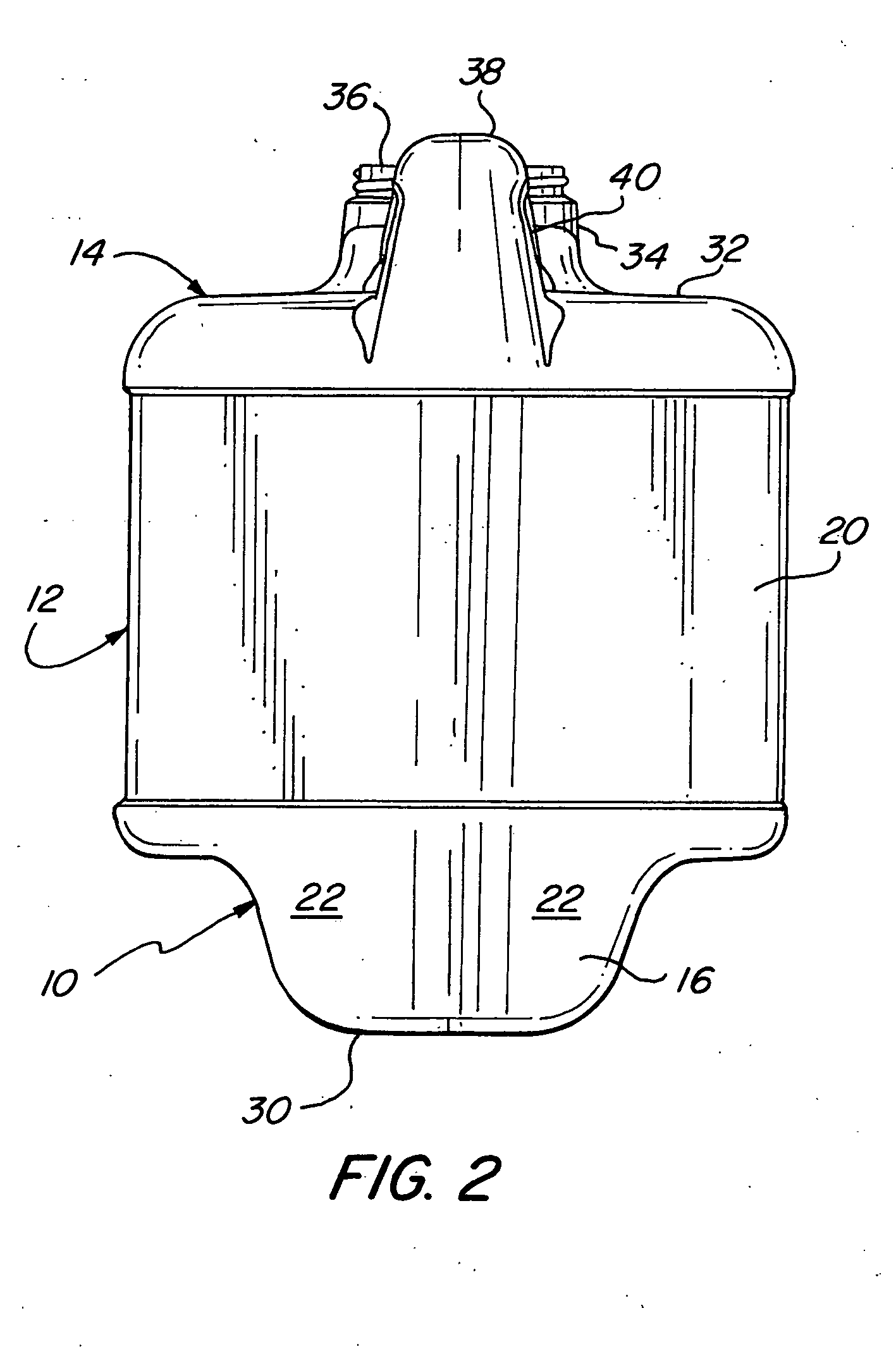

[0020] Turning first to FIGS. 1-4 of the attached drawings, a bottle A embodying the present invention has a base portion generally designated by the numeral 10, a body portion generally designated by the numeral 12 and a top portion generally designated by the numeral 14. Containers embodying the present invention can be stacked as seen in FIGS. 5 and 7.

[0021] Turning first to the base portion 10, it has a pair of legs 16 which are spaced apart diagonally so as to define a channel 18 therebetween. The general cross section of the bottle is that of a square and the legs 16 are located at diagonal corners of the square configuration. Each of the legs 16 has two outer substantially vertical faces 20,22 which are perpendicular to each other and two substantially vertical inner faces 21, 23 which converge inwardly and a projection 28 extends along the upper portion of the converging sides surfaces. The bottom surfaces 30 of the legs 16 lie in a common plane so that the bottle A can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com