Media cover for manufacturing a disk drive

a technology for media covers and disk drives, applied in the field of disk drives, can solve the problems of particles contaminating the surface of the disk, still a risk,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

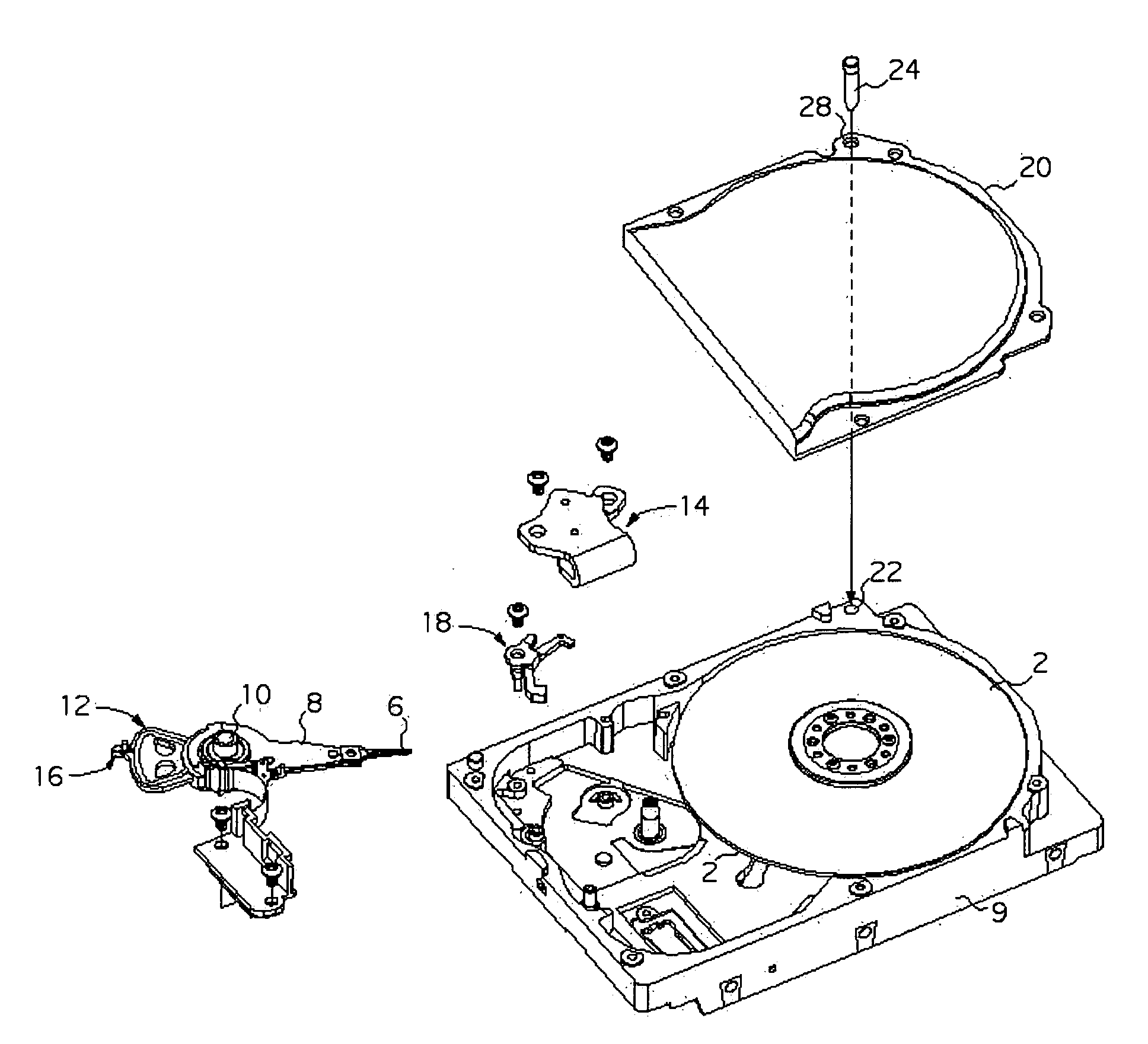

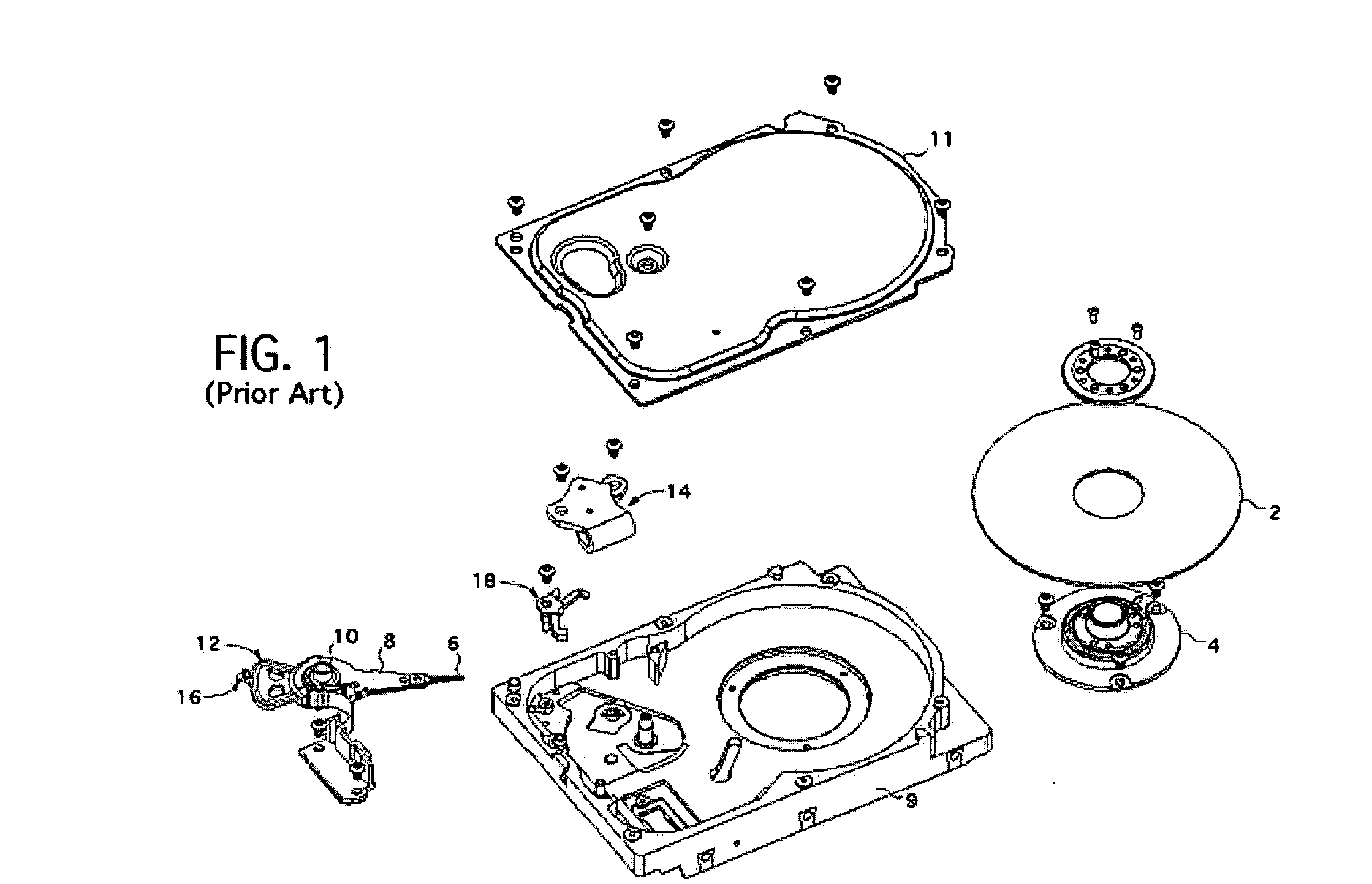

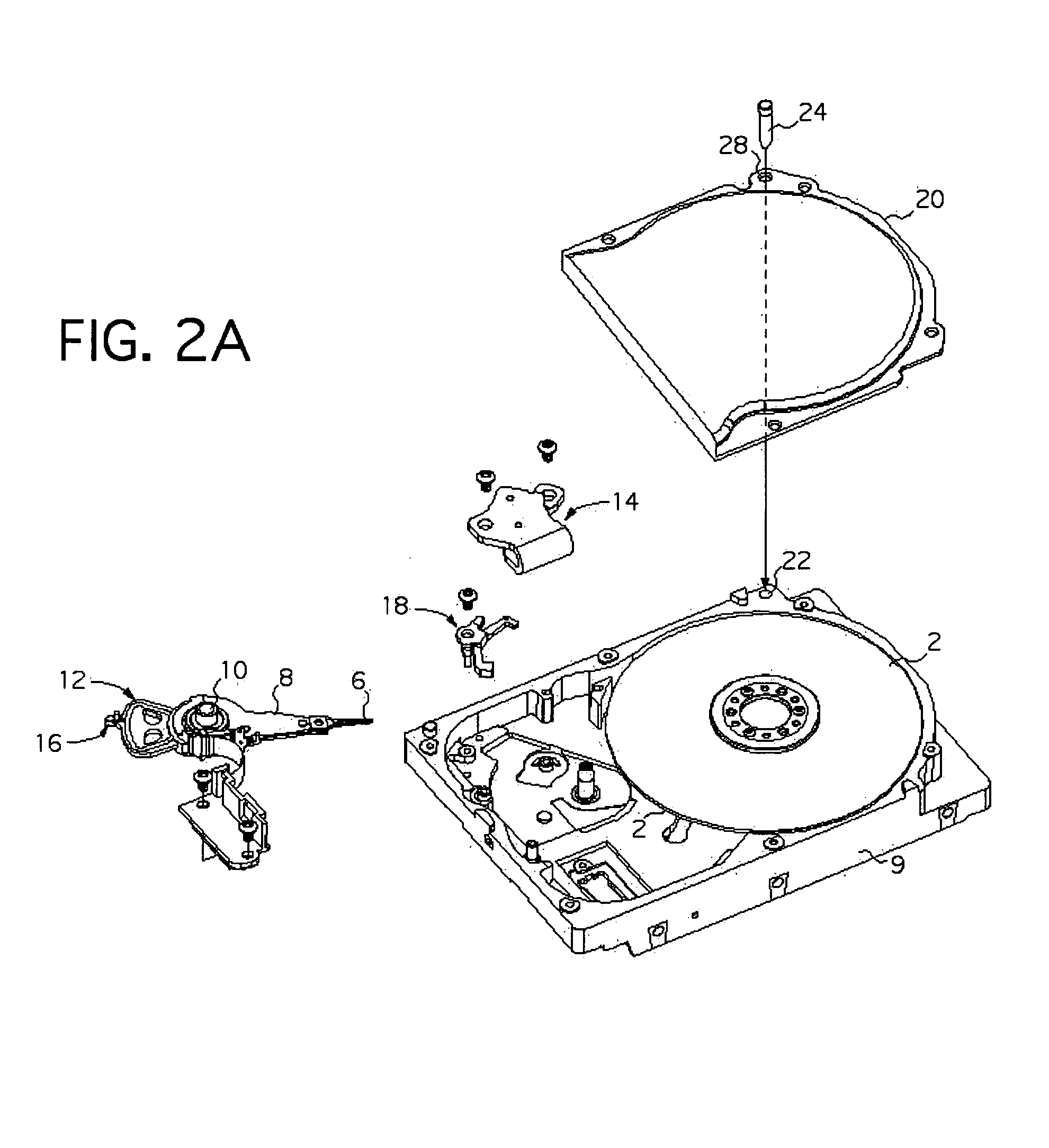

[0015]FIGS. 2A-2C illustrate an embodiment of the present invention as a method of manufacturing a disk drive. FIG. 2A shows at least one disk 2 is installed into a base 9, and a media cover 20 is coupled to the base 9, wherein the media cover 20 covers at least a portion of the disk 2 (FIG. 2B). FIGS. 2B and 2C shows how after installing the media cover 20, a head coupled 6 to an actuator arm 8 and a voice coil motor for rotating the actuator arm 8 about a pivot 10 are installed into the base 9. The media cover 20 is then removed and an HDA cover 11 is coupled to the base to form a head disk assembly (HDA) as shown in FIG. 3.

[0016]The voice coil motor may comprise any suitable components, but typically includes a voice coil 12 coupled to the base of the actuator arm 8 and a yoke 14. In the embodiment of FIG. 2A, the yoke 14 comprises a suitable flux conductor (e.g., metal) bent into an arc shape and comprising one or more magnets (not shown). In other embodiments, the yoke 14 may c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

| movement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com