Blasting system and method

a technology of blasting system and blasting method, which is applied in the direction of combustion process, combustion ignition, incandescent ignition, etc., can solve the problems of insufficient accuracy or readily available gps location data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

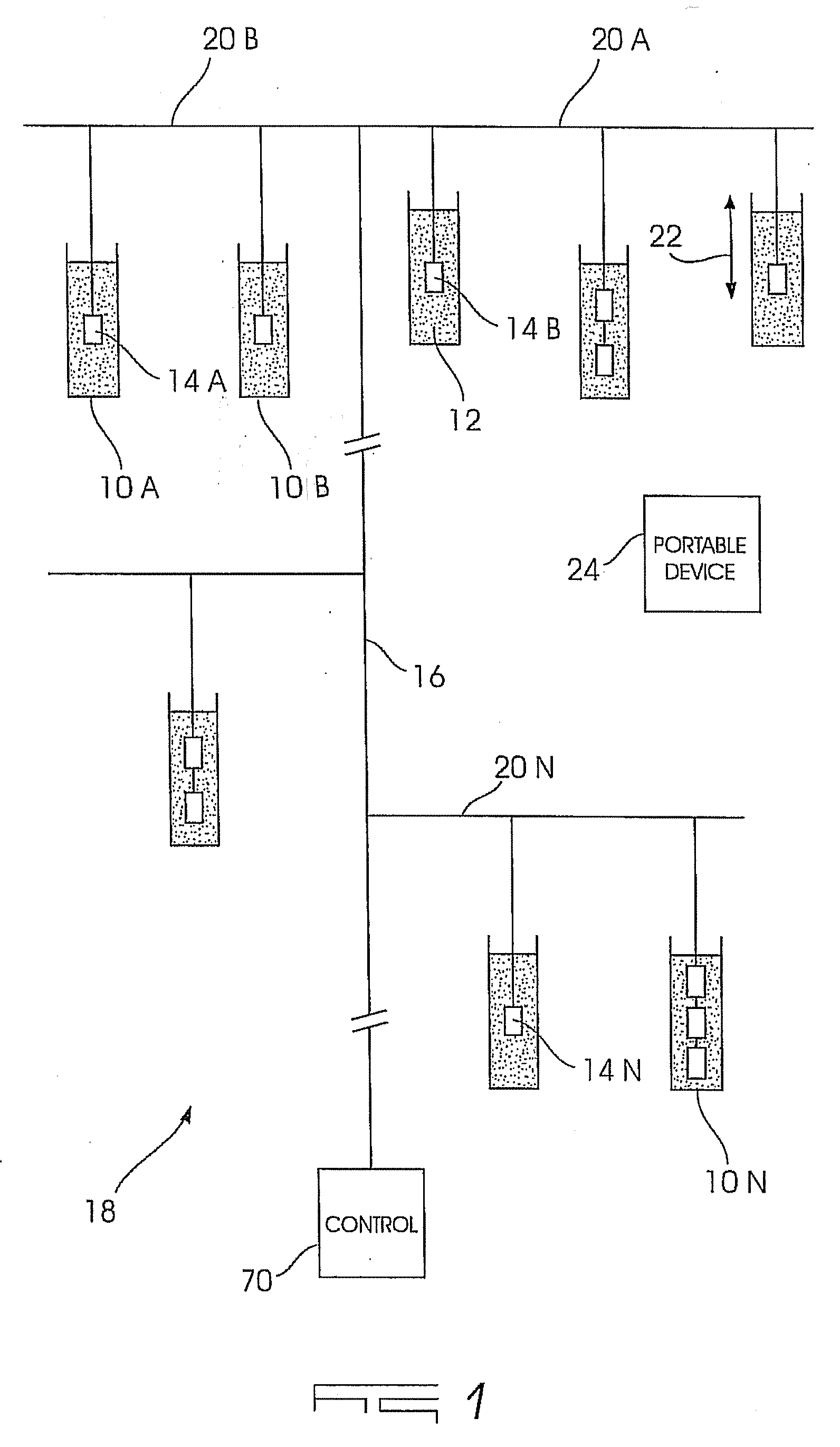

[0039]FIG. 1 of the accompanying drawings illustrates a number of boreholes 10A, 10B . . . 10N respectively formed at predetermined positions in the ground using conventional techniques. The depth of a borehole and its size may vary according to requirements known in the art.

[0040]Each borehole contains explosive material 12 and at least one respective detonator 14A, 14B . . . 14N.

[0041]A two-wire harness 16 is used to connect the detonators to one another in an array 18 which is defined by rows of detonators 20A, 20B, 20N and, within each row 20, the boreholes 10A, 10B . . . which are in the row. The array can be further particularised by the number of detonators in a borehole. As is shown in FIG. 1 most of the boreholes contain one detonator but a limited number contain two detonators and one borehole contains three detonators. A number can be assigned to each detonator when they are decked or stacked in this way and this feature also characterises the blast array. Apart from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com