Lolly Column Easy Framer

a technology of easy framing and lolly columns, which is applied in the field of can solve the problems of tedious and time-consuming framing procedure, and none of these patents provide for framing a circular cross-sectional lolly column, etc., and achieves the effect of convenient and economical use and manufacture, fast and efficient framing operation, and easy framing of lolly columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

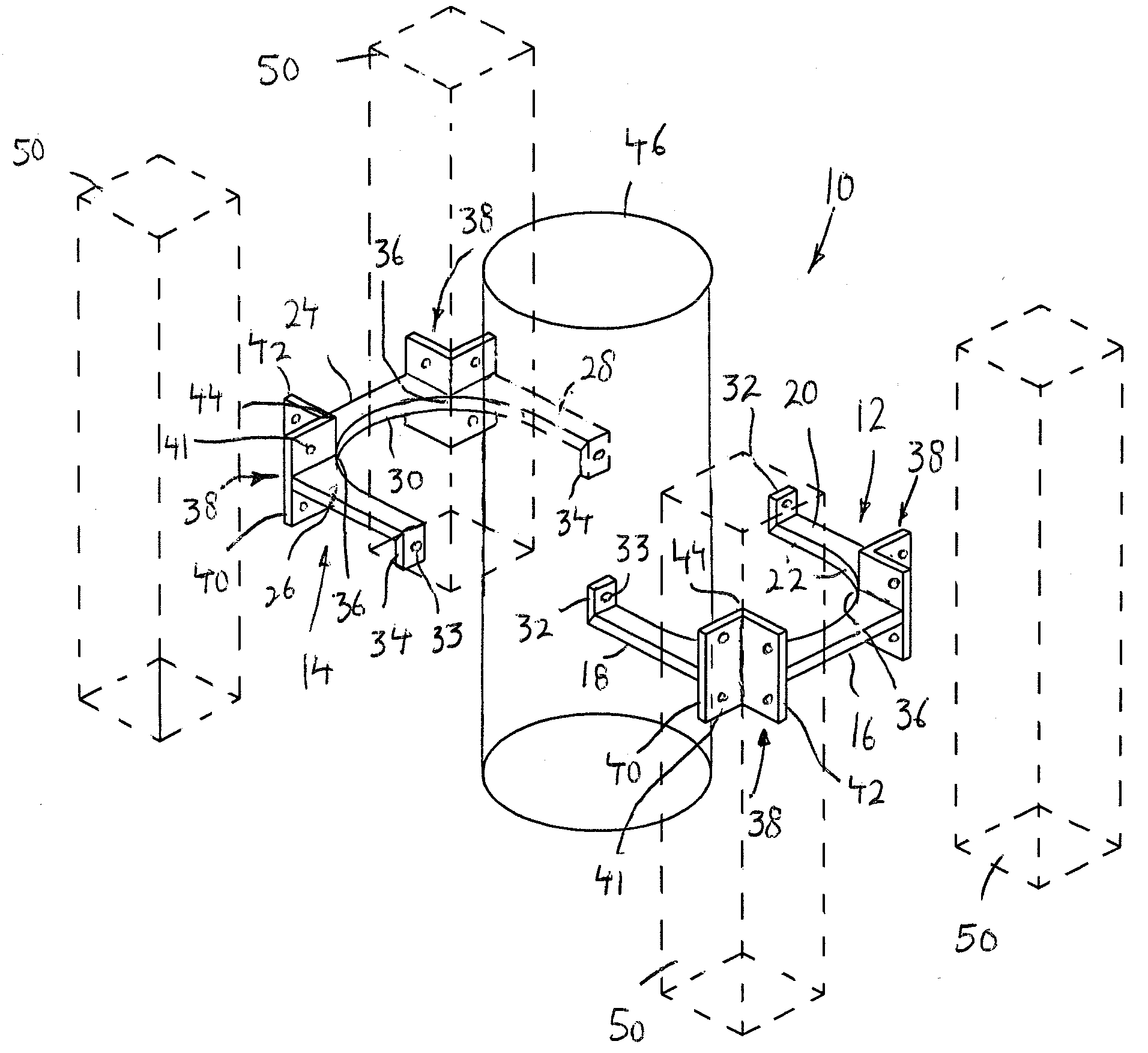

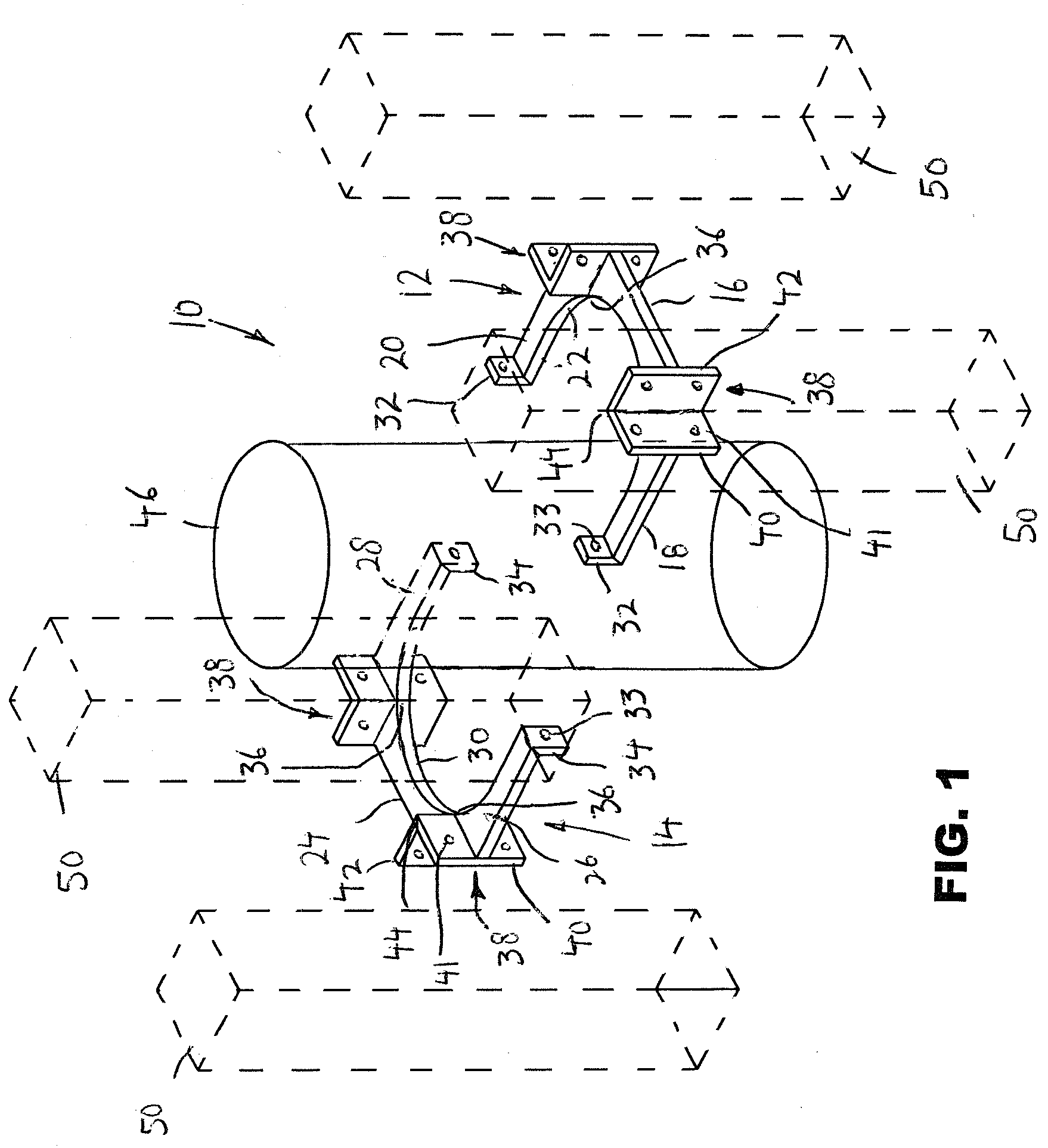

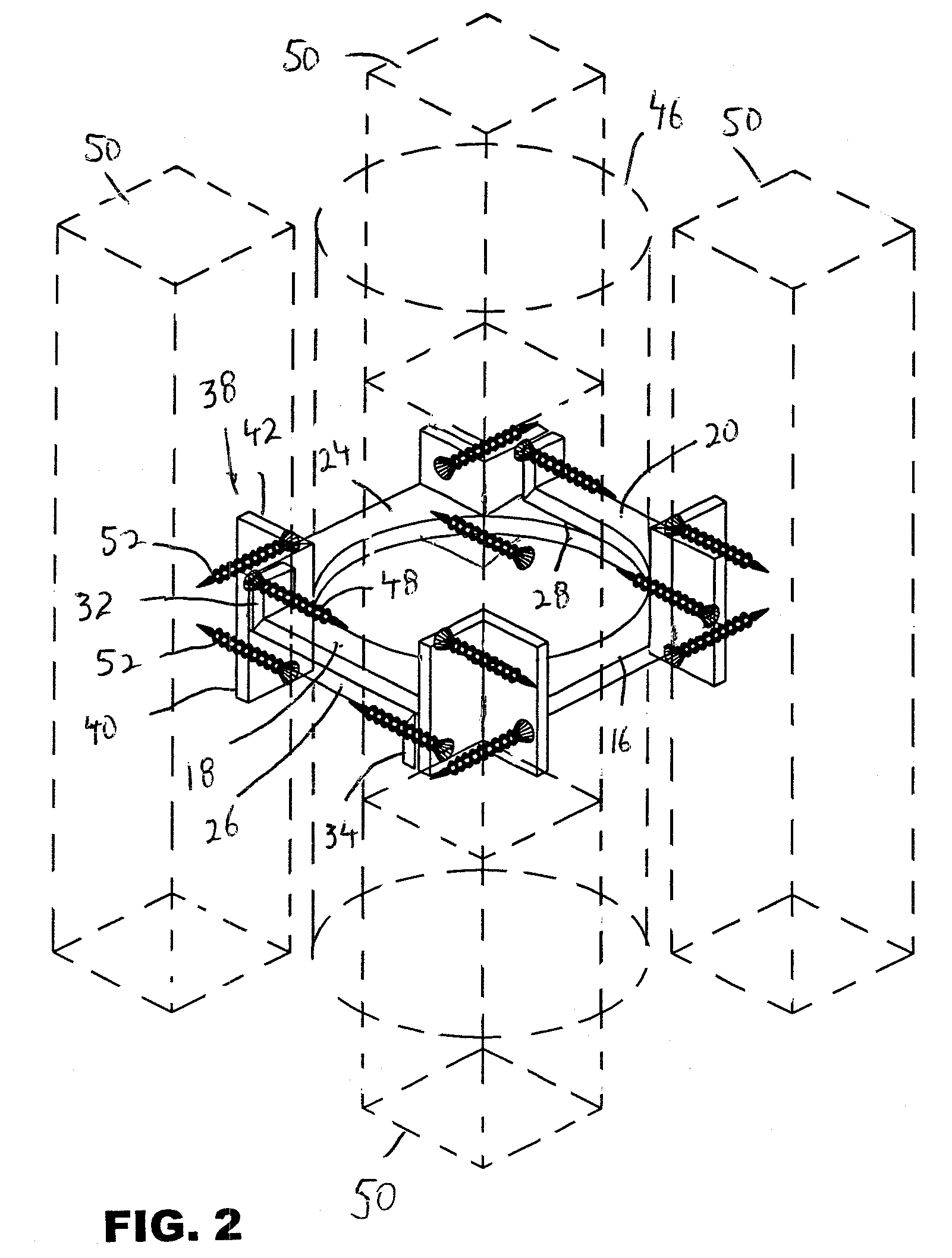

[0026]Referring to the drawings in detail, and initially to FIGS. 1-4 thereof, an arrangement 10 for easily framing lolly columns according to a first embodiment of the present invention includes a first substantially U-shaped framing member 12 and a second substantially U-shaped framing member 14.

[0027]Framing member 12 is formed by a thin, plate-like center member 16 and two thin, plate-like legs 18 and 20 extending at right angles from the ends of the center member 16 and being in parallel, spaced apart relation. Center member 16 and legs 18 and 20 are coplanar and have a uniform thickness. The inner circumference formed by the inner facing walls of center member 16 and legs 18 and 20 defines a generally semi-circular wall 22 which staightens out toward the ends of the legs 18 and 20, while the outer circumference formed by the outer facing walls of center member 16 and legs 18 and 20 defines a generally square or rectangular shape.

[0028]In like manner, framing member 14 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com