Cap structure for zipper

a zipper and cap structure technology, applied in the direction of snap fasteners, slide fasteners, press-button fasteners, etc., can solve the problems of difficult pulling of the pull tab, user's large force, complex etc., and achieve the effect of easy assembly of the zipper slid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The following detailed description is of the best presently contemplated modes of applying the invention. This description is not intended to be taken in a limiting sense, but is made merely for the purpose of illustrating general principles of embodiments of the invention. The scope of the invention is best defined by the appended claims.

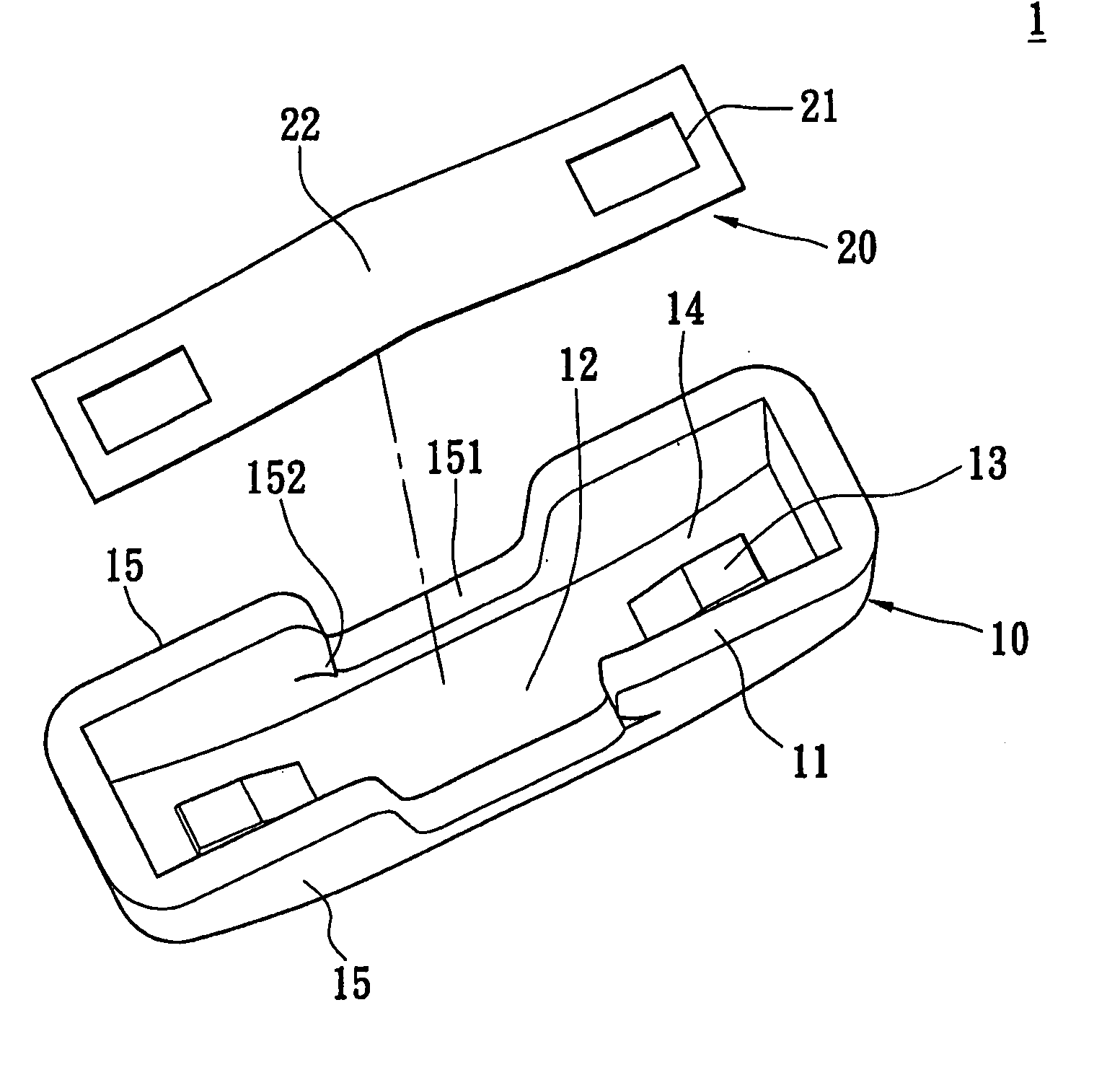

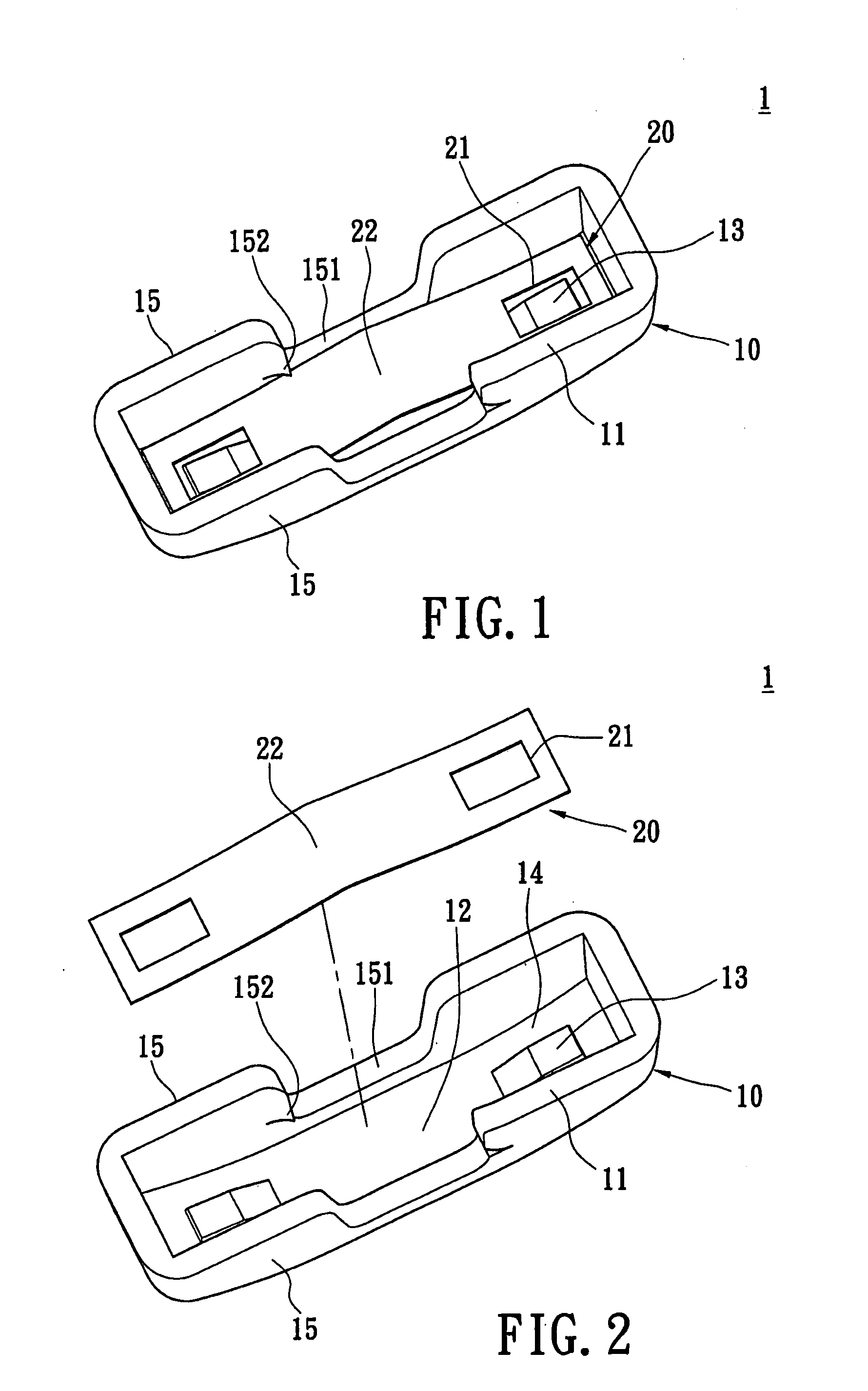

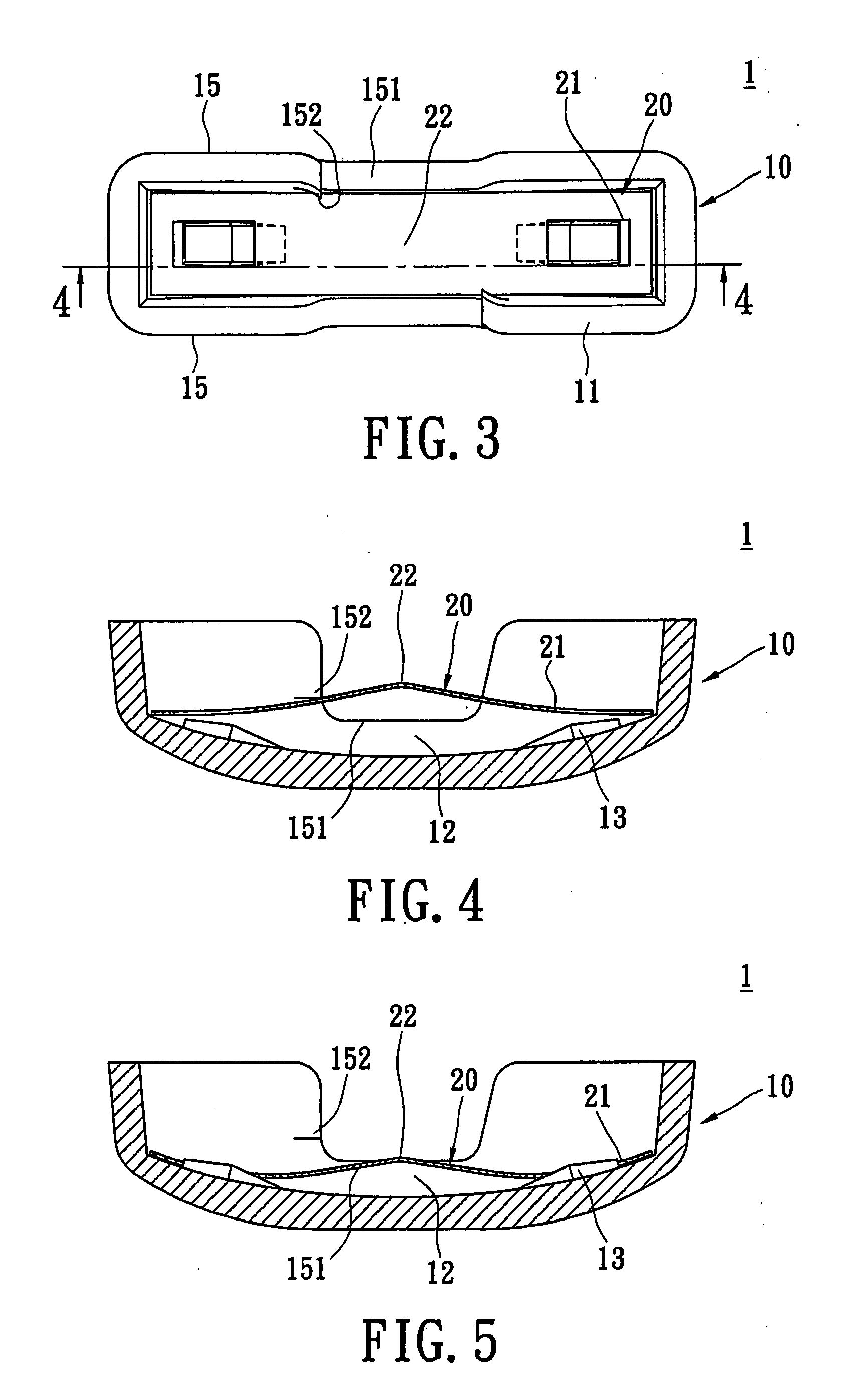

[0021]Please refer to FIGS. 1 and 4, which show a cap structure for a slide of the zipper of the present invention. The cap structure for a slide of the zipper includes a cap 10 and a resilient tap 20.

[0022]The cap 10 has a containing groove 12 formed on the bottom surface 11 thereof. Two lugs 13 are disposed on the opposite ends of the containing groove 12 respectively. The bottom surface of the containing groove 12 has a concave portion 14 between the opposite sides of each of the lugs 13 and the walls of the containing groove 12. The bottom of the concave portion 14 is lower than the top of the lugs 13.

[0023]The two lengthwise sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com