Waterproof footwear application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

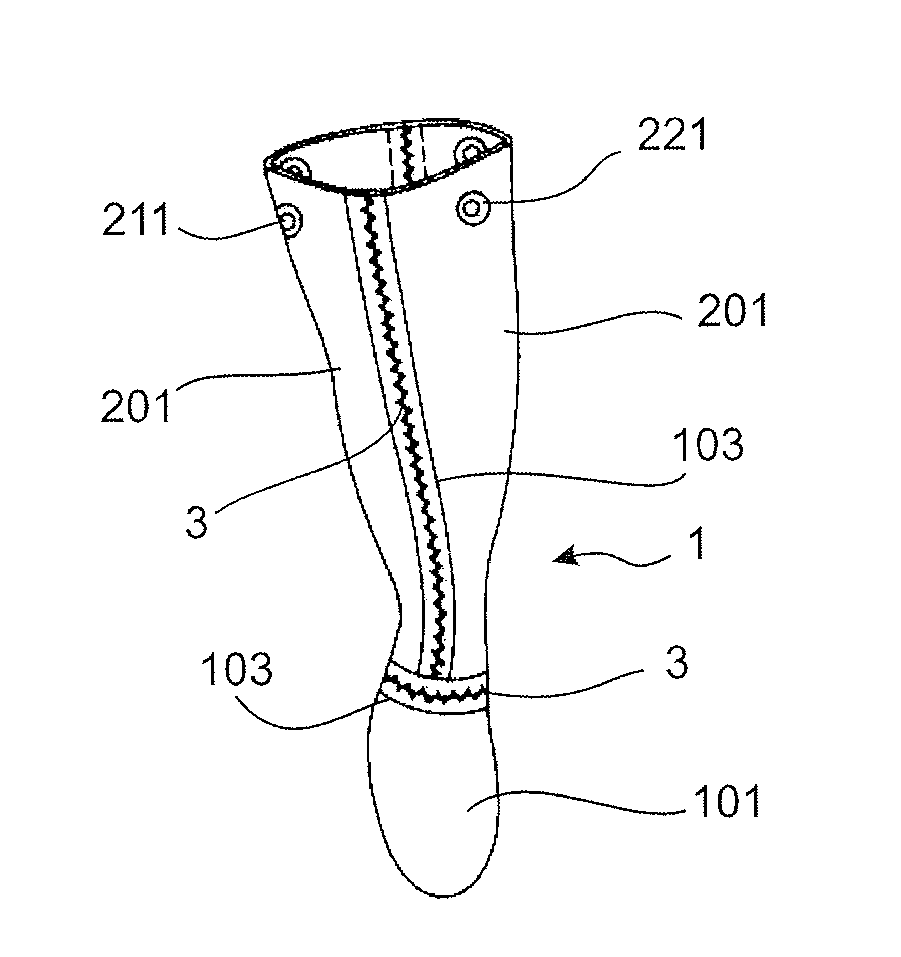

[0020]FIG. 1 shows an embodiment of the article of footwear according to the present invention, particularly a boot; reference numeral 1 denotes an upper comprising a front foot portion 101 and two rear leg portions 20; the three portions 101, 201 of the upper 1 are coupled to each other by means of stitches 3 which are covered with a strip 103 of a waterproof film. Holes 211 are formed on both the leg portions 201 at the open end of the boot, near the outlet edge thereof, and such holes are provided with reinforcement eyelet rings 221.

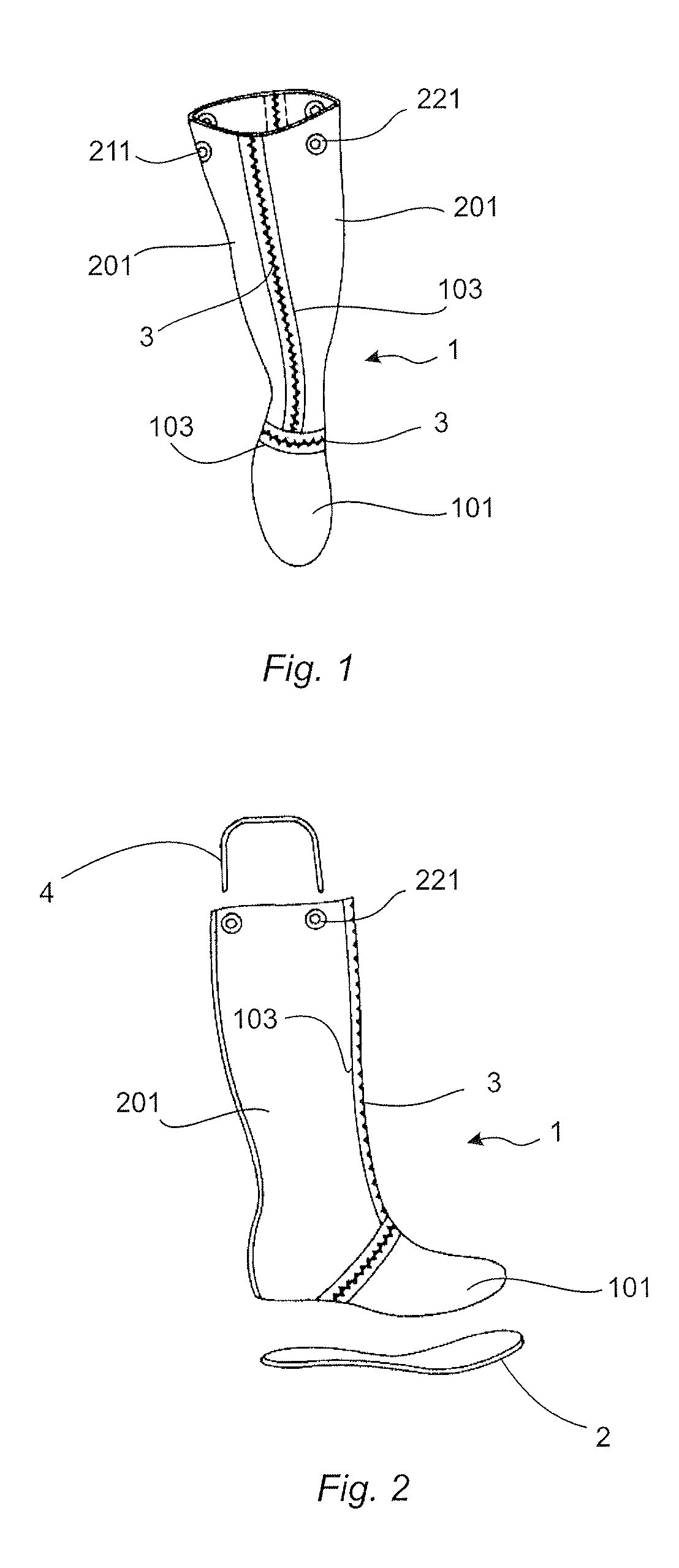

[0021]FIG. 2 shows the boot as shown in FIG. 1, in which like reference numerals refer to like parts; FIG. 2 shows a sole 2 and a ribbon-like member 4 whose ends will be passed through the holes 211 and fixed in position.

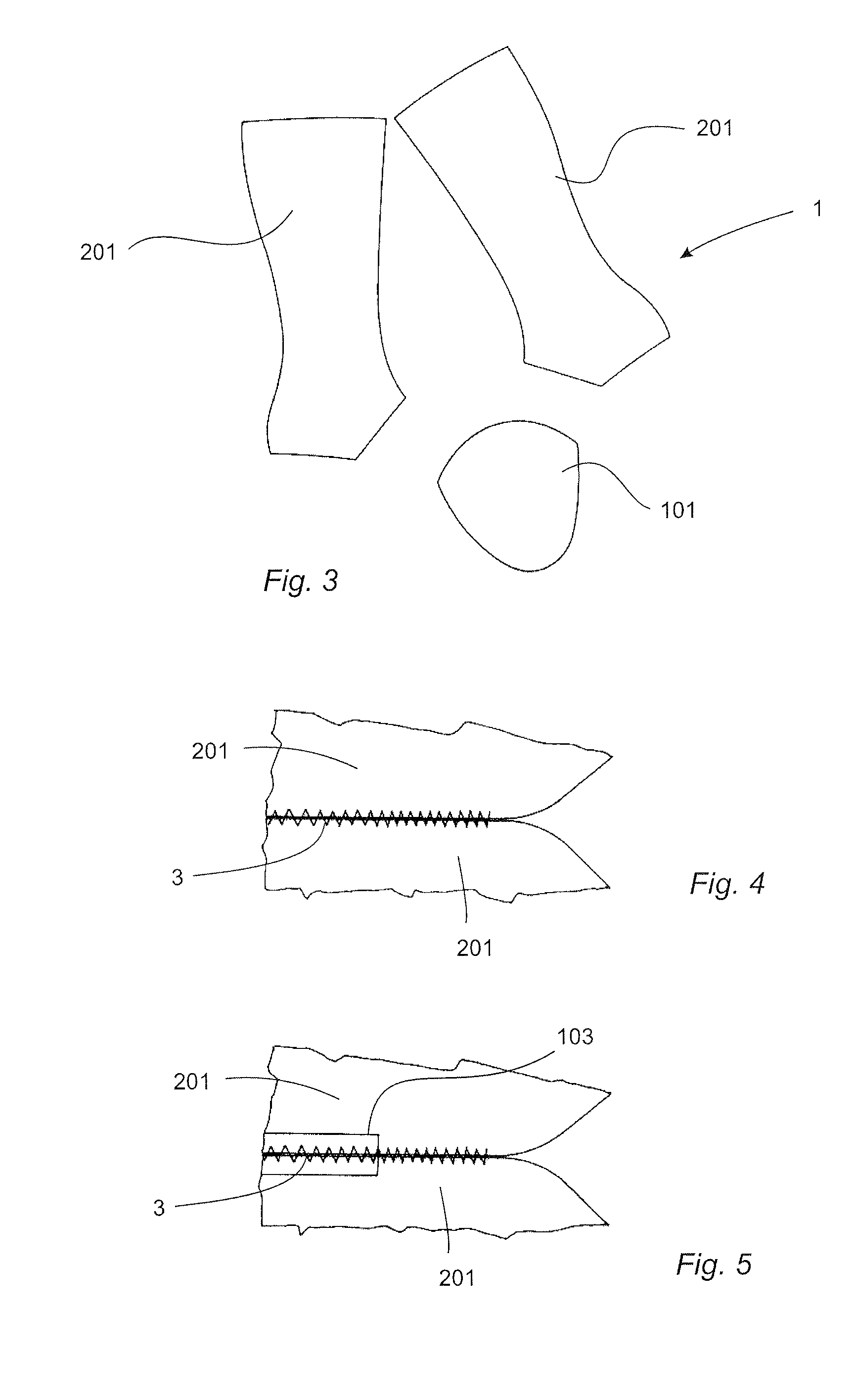

[0022]FIG. 3 shows cut-shaped waterproof material portions which are used in the process of manufacturing the article of footwear according to the present invention; as already mentioned above, the upper 1 is made up of the cut-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com