Removable Wallboard System

a wall panel and wall panel technology, applied in the direction of walls, covering/linings, constructions, etc., can solve the problems of difficult positioning of electrical, mechanical and structural features behind the wall panel, time-consuming and labor-intensive, and therefore expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

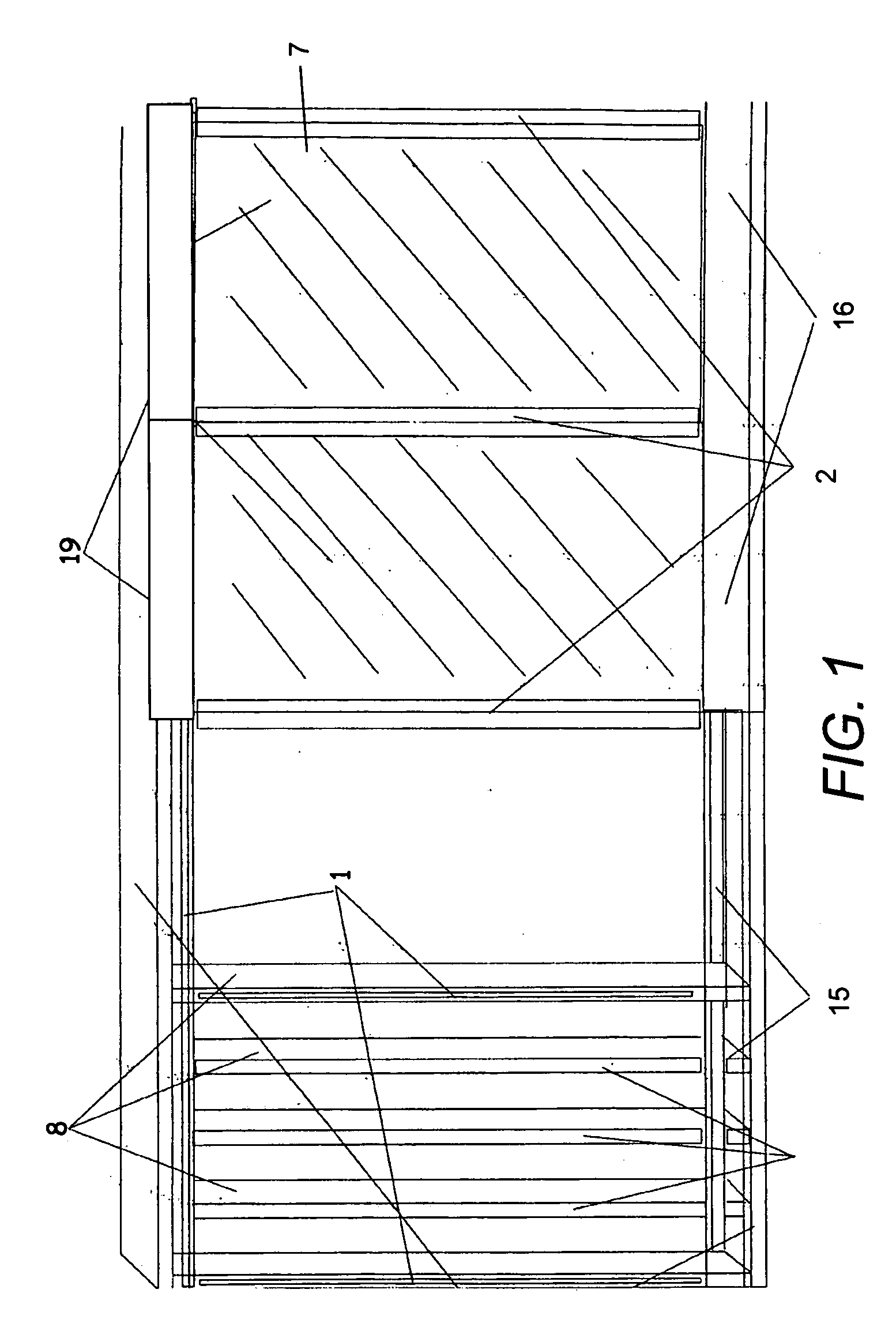

[0068]FIG. 1 is a perspective view of a section of a room having partially installed walls using the system of the present invention. A plurality of frame members 8 are installed using a traditional installation method.

[0069]Multiple receiver strips 1 are attached to support frame members 8 a specific distance apart. Wall panels 7 are positioned adjacent to a receiver strip 1 and held in place.

[0070]Trim units 2 are pressed into the receiver strips 1 such that they secure wall panels 7. Trim units 2 also act to cover the vertical seams.

[0071]Wall panel 7 is typically made of gypsum, commonly called drywall. Since this drywall is inexpensive and plentiful, this system is very cost effective. Other types of panels may also be used.

[0072]A receiver strip 1 is installed horizontally at floor height.

[0073]Base molding 16 is pressed into receiver strips 1.

[0074]Similarly, a receiver strip 1 is mounted horizontally at ceiling level. A crown molding 19 is pressed into receiver strip 1 near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com