Self-adhesive corner flashing member and method for making and using

a self-adhesive and corner technology, applied in the field of flashing members, can solve the problems of recessed window corners that are particularly difficult to seal and seal adequately, and the sealing of recessed windows is difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

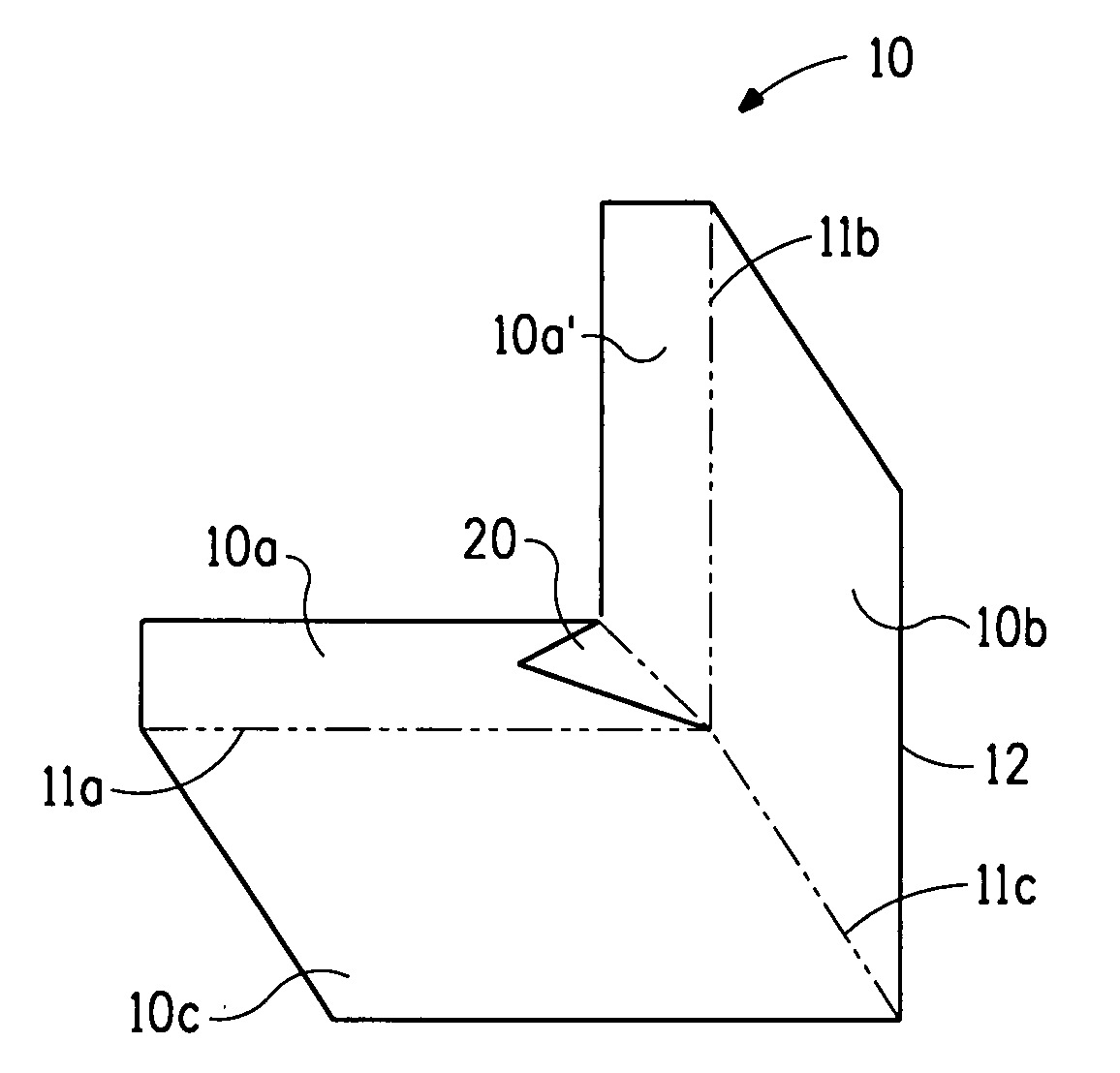

[0014]FIG. 1 illustrates a corner flashing member 10 according to the invention. Flashing material 12 has four faces in three planes, 10a, 10a′ (it is noted that 10a and 10a′ are coplanar), 10b and 10c, where the three planes are at right angles to each other in the shape of a recessed corner. The three planes share three common edges 11a, 11b and 11c. The corner flashing member is free of seams or holes through which water could infiltrate behind the flashing. The flashing material is elastic, conformable and flexible such that it can not only fit into the recessed corner of a recessed window, but it may also be extended and wrapped around the exterior wall. The length of the flashing material on either side of the corner is at least about 1 inch, and is typically about 6 inches.

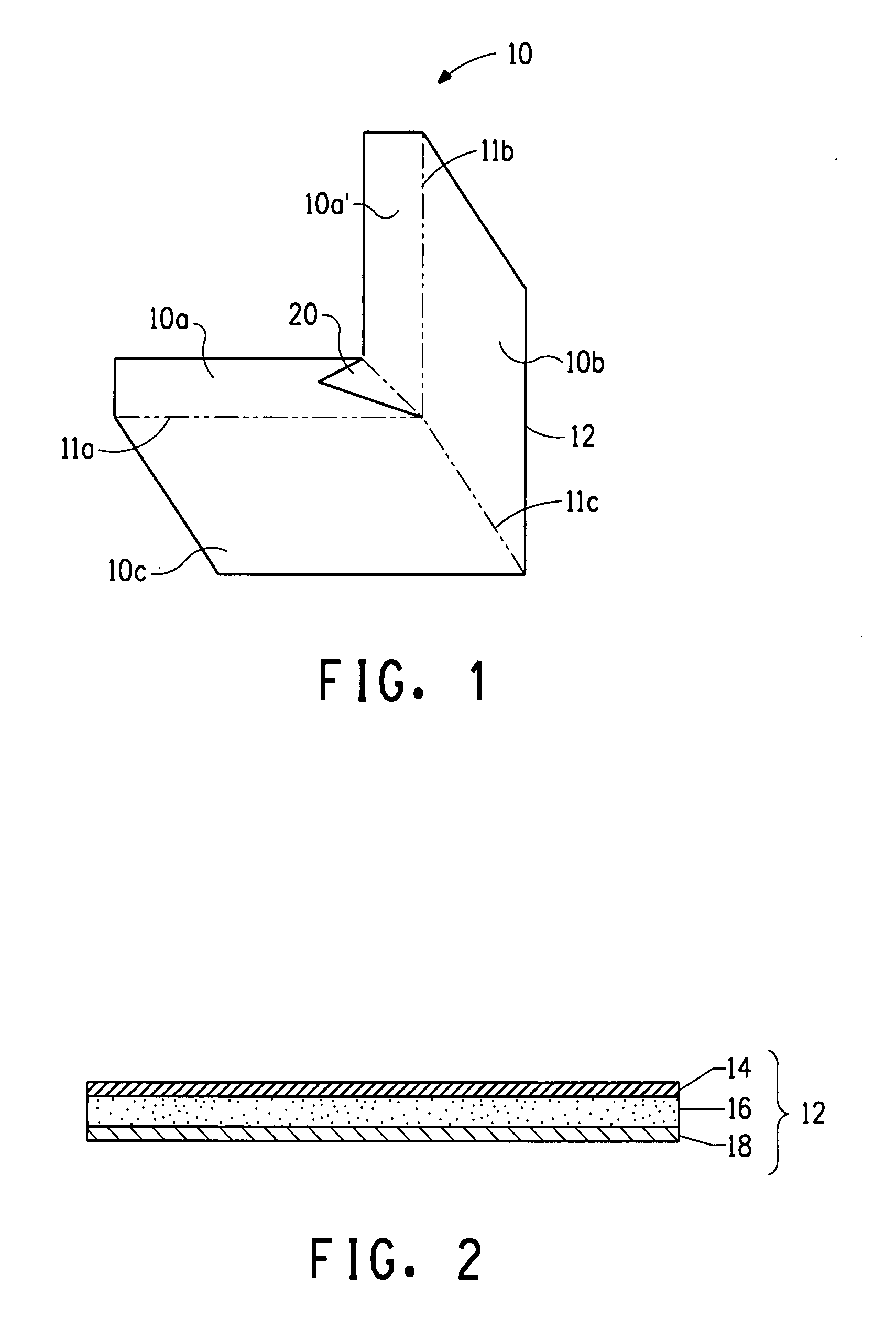

[0015]FIG. 2 illustrates a cross section of the flashing material 12. Flashing material 12 has a topsheet 14, a pressure sensitive adhesive layer 16 on one surface of the top sheet and a release sheet 18 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com