Dynamic heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

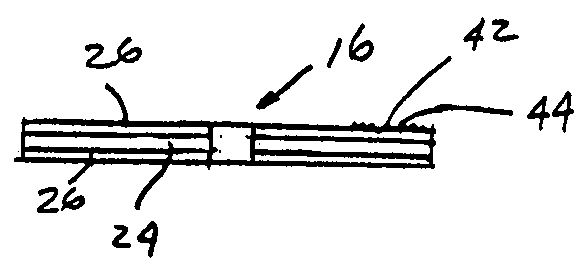

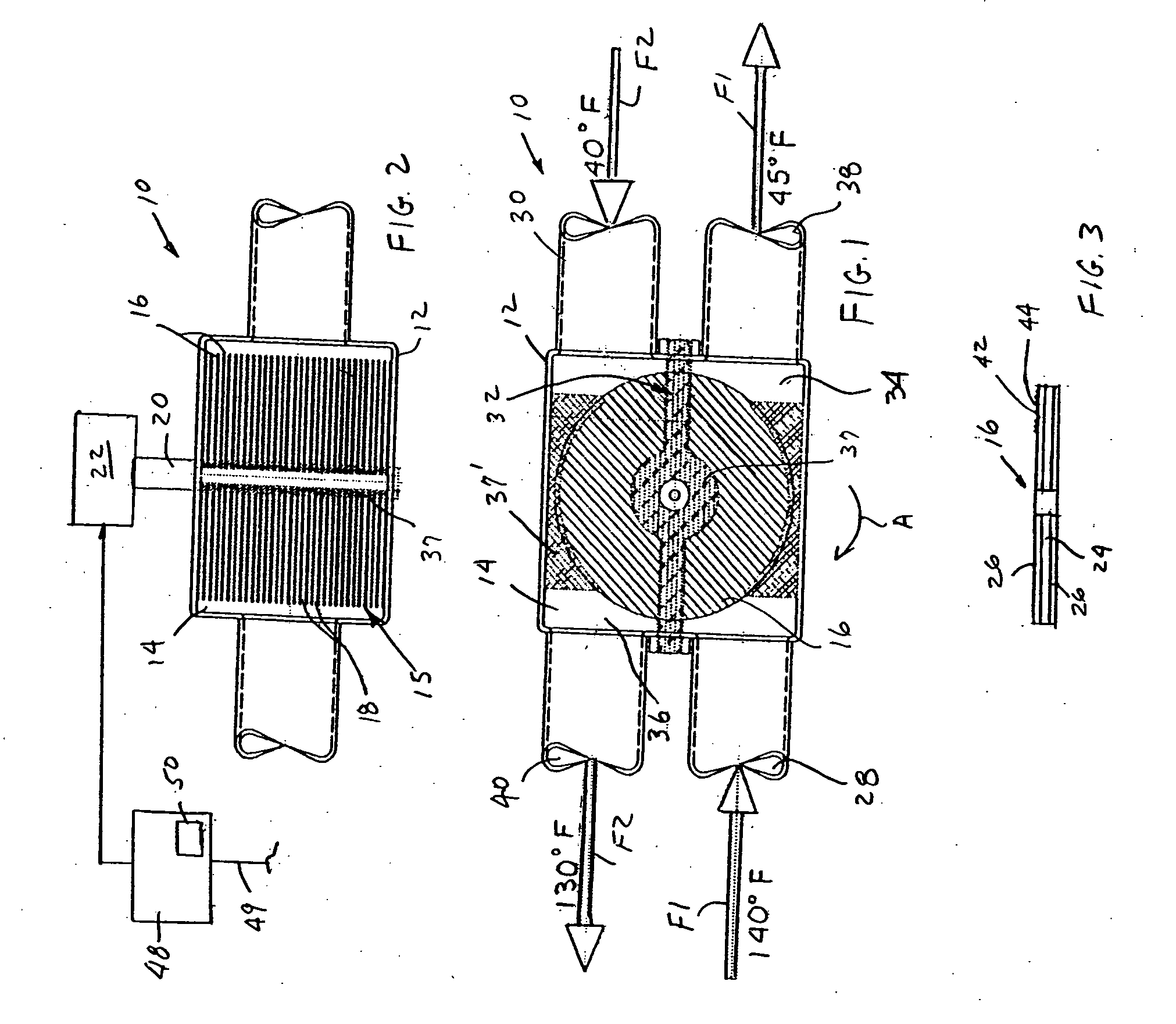

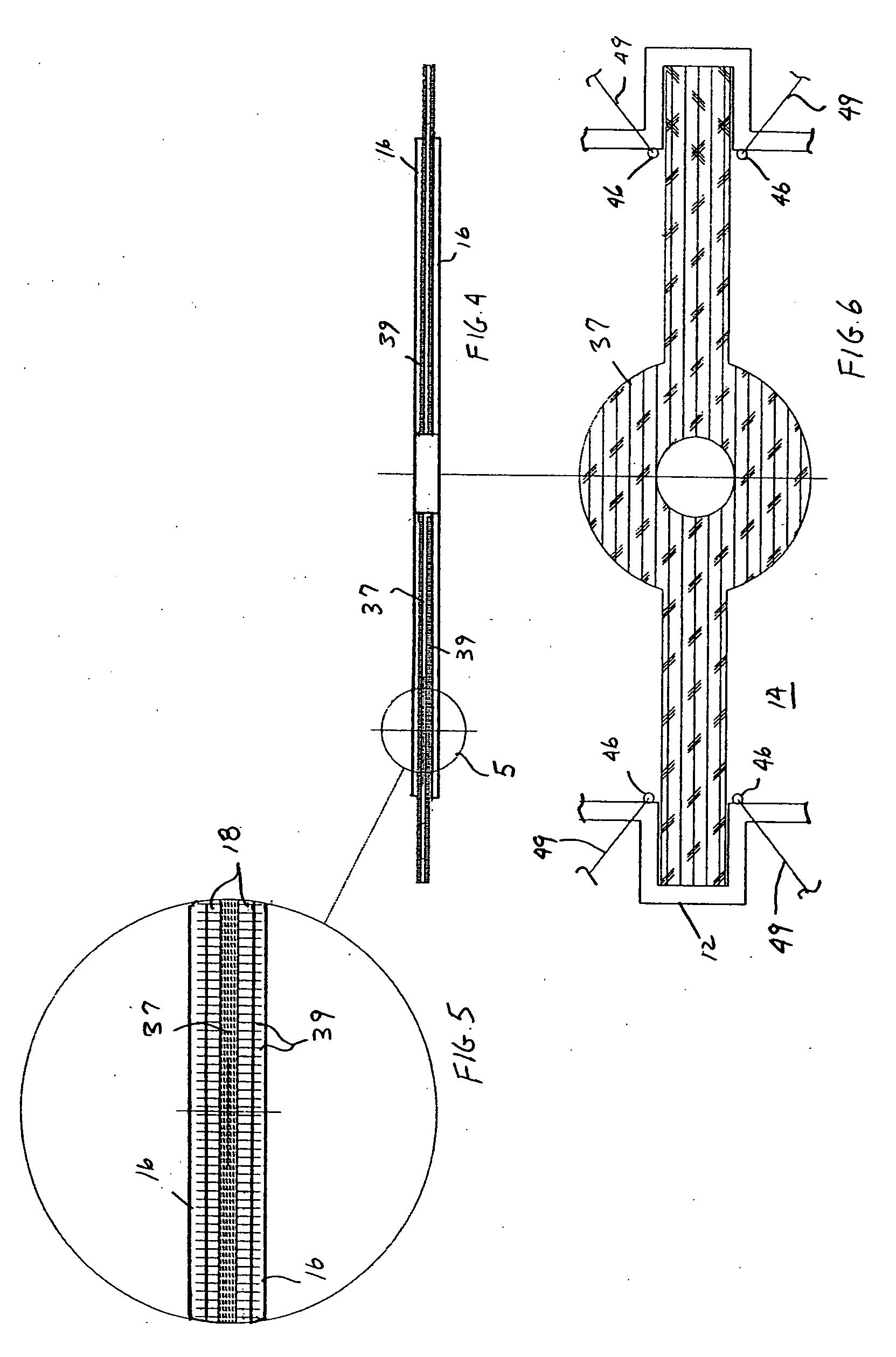

[0015]With reference to FIGS. 1 and 2, a rotary heat exchanger for heat exchange between at least two fluids is shown, generally indicated at 10, in accordance with an embodiment of the invention. The rotary heat exchanger 10 includes a housing 12 defining an interior space 14. Heat transfer structure, generally indicated at 15, is provided in the interior space 14 and in the embodiment is in the form of a plurality of concentric, plate-shaped members or discs 16 disposed in spaced relation to define passageways 18 (FIG. 2) between the discs. Each disc 16 is mounted for rotation within the housing. More particularly, with reference to FIG. 2, each disc 16 is coupled with a common shaft 20 that is rotated by a motor 22. Each disc 16 is coupled at central portion thereof to the shaft 20. The shaft 20 can be part of the motor 22 or coupled with a shaft of the motor 22. The discs 16 can be a structure made from a single material having high thermal conductivity (e.g., copper). However, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com